3D Printing Applied to Fluid Power

Aidro is now designing and manufacturing fluid systems with metal additive manufacturing technology with the goal to reduce both material waste and production times. Among the components which have already been 3D printed are hydraulic manifolds, heat exchangers, spools and valve blocks.

by Elena Magistretti

One year after the official presentation of the hydraulic solutions 3D printed in metal at Hannover Messe, Aidro Hydraulics is still pursuing this direction with new developments, attracting great international interest.

The additive manufacturing technology or 3D printing, which is spreading in various industrial sectors, such as automotive and aeronautics, is still standing on the threshold when it comes to hydraulic applications.

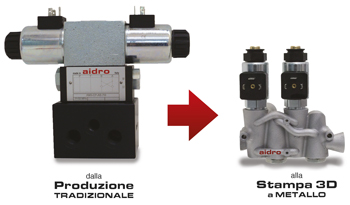

Complex hydraulic components produced with metal 3D printing can incorporate details that would be difficult or impossible to duplicate through conventional machining; beside that weight and size are reduced without compromising performance. Aidro is now designing and manufacturing fluid systems with metal additive manufacturing technology. In March, during the technical forum IFK (International Fluid Power Conference) in Aachen, the company presented several solutions showing the transformation from conventional to 3D printed products to the major experts in this field.

The advantages of 3D printing hydraulics

Metal 3D printing holds many advantages over subtractive manufacturing techniques, including reducing material waste and cutting production times. When it comes to hydraulics, where the internal design of the component makes all the difference, 3D printing is particularly useful. Firstly, a component can be completely redesigned to minimize weight and space. In case of hydraulic manifolds, they may be up to 75% lighter. This is especially important in mobile applications. Secondly, the internal geometries of the component can be redesigned to optimize flow and reduce pressure drop. Moreover, the potential leakage from the auxiliary drilling and plugging is thoroughly eliminated (these are no more required as in the CNC milled hydraulics). In fact, 3D printing overcomes the limitations of traditional manufacturing by positioning flow channels precisely where they are needed and in a variety of shapes and sizes. This means flow channels can be spaced closer together than with conventional manifolds, which makes the finished product more compact and lighter. Furthermore, passageways connecting two or more internal channels don’t have to be machined from outside the manifold and subsequently the channels can have curved shapes. However, 3D printing isn’t limited to manifolds. Valve components themselves can also benefit from 3D printing. For example, valve spools usually contain circular flow paths, primarily because machine tools use rotating cutting tools. Instead, making flow paths with square cross-sectional areas instead of circular could increase flow capacity, thanks to the larger area of a square compared to a circle of the same width. Other examples are the heat exchangers produced with additive manufacturing, in smaller size and with higher performances.

The additive manufacturing process

Aidro is 3D printing a range of components, including hydraulic manifolds, heat exchangers, spools and valve blocks. The materials used depend on the amount of pressure the component will undergo. With metal 3D printing, Aidro can manufacture parts out of Stainless Steel (AISI316L) and Aluminium (AlSi10Mg). These are the main used metals in hydraulics, but with this new technology also other materials are available, such as Inconel, Maraging Steel or Titanium. Hydraulic components are initially designed in CAD software and specific additive manufacturing softwares and analyzed using finite element method (FEM). They are then 3D printed with additive technology based on metal power bed melting (called direct metal laser sintering o DMLS). Then, they are subjected to material testing, pressure resistance measurement and dimensional control via 3D scanning. Finally, the components are CNC milled, where a specific coupling is required, and heat treated.

Solutions Center for Additive Manufacturing

According to Alberto Tacconelli, Aidro Managing Director, the 3D printing technology allows the internal channels of the valve block to be optimized to achieve a greater flow in a smaller space. Furthermore, the mechanical proprieties of the 3D printed materials are equivalent to metals produced from bar stock (and better than casting metals). After investing in metal 3D printers in the past few years, Aidro is now 3D printing metal components on a regular basis. Thanks to the team of engineers who specialize in additive manufacturing, Aidro set-up a Solutions Center for Additive Manufacturing in Hydraulics (SCAMH) where the AM specialists design new hydraulic solutions basing on customers’ requirements while offering services to companies wishing to approach this technology.