Linear stage control for precise positioning

To control its PRO-LM series positioning tables, Aerotech offers the Automation1 platform, which combines the control of positioning systems and process tools. This platform uses the HyperWire fibre optic bus and includes a series of drives. This solution will be showcased, among others, at “SPS – smart production solutions” in Nuremberg.

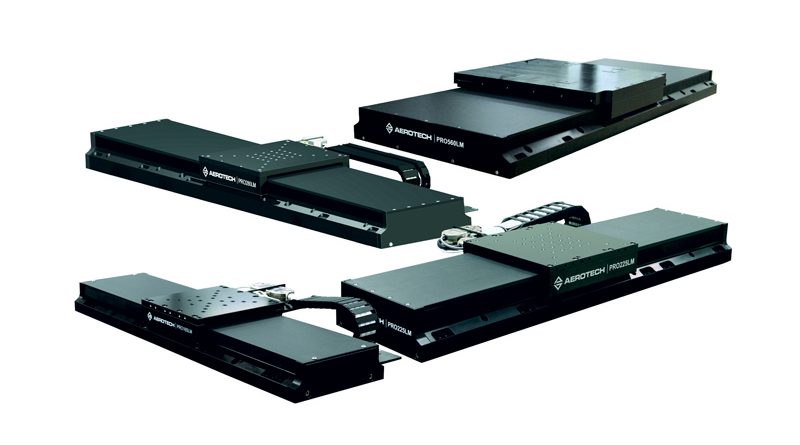

The PRO series positioning tables family is available with direct drive linear motor or ball screw options. Four of the direct-drive linear motor stages are available: a PRO115LM installed on a PRO165LM and a PRO190LM installed on a PRO225LM. The tables are capable of high-speed motion with very good velocity regulation. However, it is not only the speed and positioning performance that is characteristic, but also their robustness. The sealed mechanical bearings make the PRO-LM linear tables insensitive to any kind of contamination. The linear stages are equipped with a low-friction sealing system, which sustainably reduces maintenance in industrial applications.

Allows precise control with the dedicated platform

Due to their high rigidity and fundamental precision design, the linear stages have proven themselves many times over in production processes with high cycle rates. Users of the high-performance linear stages benefit from the proven industrial linear motors and ball screws with improved positioning accuracy, according to Aerotech. Aerotech developers promise up to 98% better resolution whilst repeatability and geometric error motion have also been significantly improved compared to conventional linear tables. The control system also contributes to this: with Automation1, Aerotech has combined the control of positioning systems and connected components onto one platform, which is specially equipped with a new software-based motion controller. Automation 1 connects with HyperWire, the most powerful motion bus in the motion control industry.

Turnkey machines for automated processes

Since such linear tables are usually integrated into production systems or automation processes, Aerotech sees providing more of the total solution where motion performance is important as a key area of growth in the future. Custom-designed motion subsystems include positioning systems on granite structures with undercarriage and vibration isolation, as well as external measurement systems. Integrated systems are near turnkey machines designed with customers to run an automated process. These include not only Aerotech precision motion control components, but also full automation integration for such things as parts handling, process instrumentation, safety features and custom software. Aerotech has a high level of vertical integration, particularly in drive components and controls.