Designing 3D Printed Actuators with Artificial Intelligence

A group of researchers from the Center of Complexity and Biosystems of the State University of Milan created an algorithm to design high efficiency metamaterial actuators, going beyond traditional human design; the designed structures were then printed in 3D. The work was funded by the European Research Council and published in the journal “Nature Communications”.

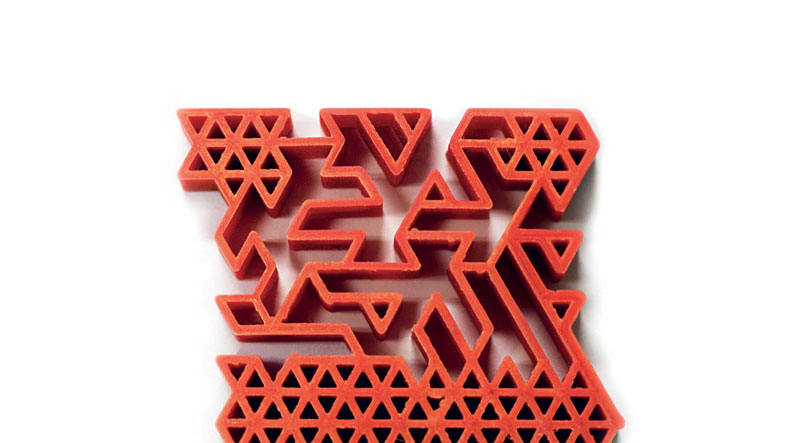

Mechanical metamaterials actuators achieve pre-determined input-output operations exploiting architectural features encoded within a single 3D printed element, thus removing the need of assembling different structural components. Actuators are currently used in many applications from machines to robots. A team of researchers from the Center for Complexity and Biosystems of the University of Milan used artificial intelligence (AI) to design metamaterial actuators with high efficiency, surpassing traditional human design. Designing materials with tailored mechanical properties and functionality still remains a great scientific and technological challenge, with huge potential for engineering applications and societal gains.

A revolutionary approach of recent years has been to focus on materials that are structured on the macroscale producing mechanical metamaterials, a novel class of artificial materials engineered to have exceptional properties and responses that are difficult to find in conventional materials.

These peculiar properties find natural applications in industrial design, as architectural motifs or reinforcement patterns for textiles, beams and other structures.

Machine design beats human design

The increased focus on metamaterials is stimulated by the recent advances in digital manufacturing technologies, such as 3D printing, which enable an easier design of such material structures with the removal of many of the constraints in scale and geometry at low cost. In metamaterials actuators constituent cells work together in a well-defined order to obtain a desired macroscopic movement. Current design strategies for metamaterial structures and machines are essentially based on manual operations, but CC&B researchers showed that AI can improve considerably the design process.

The team combined different computational algorithms to be able to optimize the response of the actuator and then compared the efficiency with human designed actuators: machine design always beats human design. They have also tested that the predicted structures could be 3D printed and confirmed their high efficiency. The algorithm they devised has practical applications for human-machine interactions as interactive/responsive components. The team is currently pursuing a commercialization strategy thanks to the support of the European Research Council.