A Broader Range of Couplings for Servo Drives

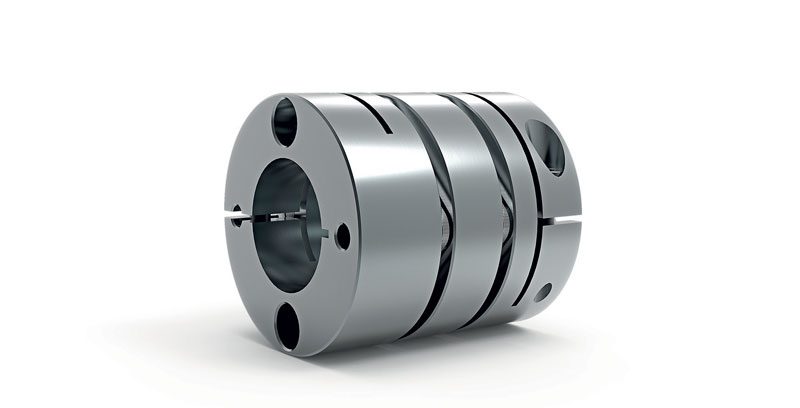

R+W broadened its range of SCL disc pack couplings, ideal for servo drives, by introducing its new SCL1 and SCL2 couplings. Particularly compact, they are suitable to transmit torque values from 25 to 100 Nm.

by Elena Magistretti

Servo drives are used especially where great precision and high dynamics are required, as often happens in the case of automated machinery, packaging lines, machine tools or Cartesian robots.

Couplings used in these applications must make up for misalignments, operating with maximum precision and with a low inertia. Experience accrued during the years led R+W’s designers to introduce this new series of products within the range dedicated to high-speed automation.

These couplings are particularly suitable for high dynamics application; they are made up of aluminium hubs and highly flexible stainless steel disc packs. Aluminium hubs allow a minimum weight and a very low moment of inertia, while the stainless steel disc packs allow transmitting torque with very high torsional rigidity and with a high compensation of misalignments. They may be fixed with high strength screws which transmit torque by means of a friction connection, eliminating backlash completely, with no micro-movements and a greater torsional rigidity. The connection between the shaft and the hub is available with clamping systems, screws or conical shrink discs.

Preventing bearing damages caused by overheating

Modern servomotors enable a high motion control. Couplings play an important role in the compensation of misalignments and in precise torque transmission. The coupling’s design properties allow it to compensate axial, angular and lateral misalignments. Exerted forces are low, preventing the overheating of the bearings normally inserted in the kinematic chain. There are two instances when SCL couplings are to be preferred over metal bellows couplings; the presence of misalignments, which SCL couplings can compensate to a greater degree, and the need for a fast replacement, for instance in case of a fault, since the modular design of the disc pack couplings makes it possible to replace rapidly a coupling or even a single hub. When designing transmissions, engineers must consider multiple variables which interact reciprocally, such as, torque value, torsional rigidity, reaction load, moment of inertia, balance and backlash. R+W’s research and development team always considers these complex properties when designing its couplings. The experience accrued by R+W in the industry is the foundation of the capability of creating products with superior properties.

Both weight and moment of inertia are reduced

R+W’s disc pack couplings are characterized by their compact size. Hollows around the clamping screws ensure the reduction of floor space; materials used contribute to the reduction of weight and of the moment of inertia, which is very important in high dynamics applications. The compact size of SCL couplings provides designers with great flexibility. SCL couplings include high strength steel discs which are oriented so as to obtain a high torsional rigidity. Packs are positioned with a 90° rotation with respect to each other. The direction of lamination of the steel used therefore has no negative impact on the coupling’s torsional rigidity. The steel used for these couplings was developed purposely for this reason and therefore has a high strength as well as remarkable elastic properties. This is the reason why it can withstand all the forces applied to it during torque transmission. R+W’s disc pack couplings are delivered preassembled. There is no need to worry about assembly, they just need to be installed; preassembly carried by R+W’s experts prevents mistakes while saving time. SCL couplings are ideal for precision transmissions where couplings with lower torque values are needed, from 25 Nm to 300 Nm. They have been designed to operate constantly during the machine’s entire working life.