A Hybrid Actuator Solution for Axle Testing

Moog and their customer Meritor jointly developed the Electro-Hydrostatic Actuator System (EAS), subsequently creating a test bench for axle fatigue testing at Meritor’s Cameri laboratory near Novara. This application demonstrates Moog’s hybrid technology, and how this technology guarantees the function and performance of electrohydraulic cylinders, albeit totally electronically controlled. The system offers many advantages, including a notable reduction in energy consumption, less maintenance and significantly improved levels of safety.

di Silvia Crespi

Moog’s ‘Total Solution’, introduced at the recent SPS IPC DRIVES Italia trade show in Parma, combines electric, hydraulic and hybrid technologies in a ‘technologically neutral’ approach designed to meet specific customer demands across many types of application. Among the most interesting solutions showcased at SPS Parma was the Electro-Hydrostatic Actuator System (EAS) developed jointly with Meritor. The Moog stand also featured the innovative LMS (Large Motor Solution), an integrated system for primary movement control used with servo presses.

Successful application for the hybrid system

The Electrohydrostatic Pump-Motor Unit (EPU) is a new generation hybrid system that combines the best of electrohydraulic and electromechanical technologies. It boasts the low energy consumption of an electrical system, as well as the high reliability of hydraulic systems and the easy energy storage of failsafe movements. The unit is available both as a single product and as an integrated solution – the Electrohydrostatic Actuator System – that connects the electrohydrostatic pump motor unit with whatever additional component the customer may require.

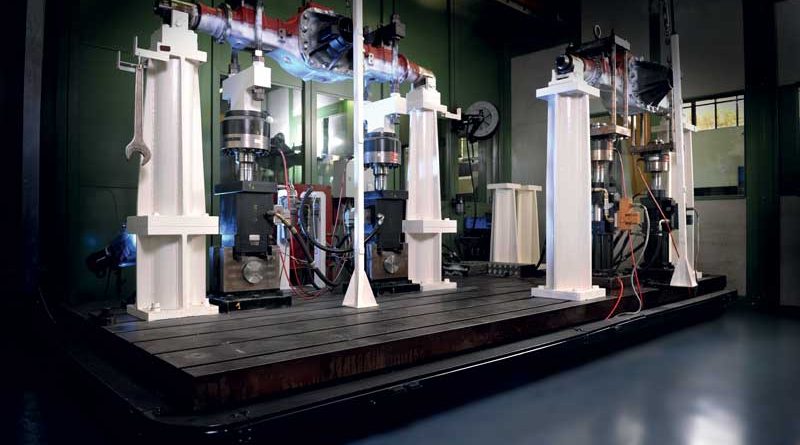

One successful application of this technology has been the test bench for axle fatigue testing recently developed at Meritor’s test lab in Cameri. The US multinational company provides integrated systems modules and components, such as vehicle axles and suspension braking systems, for the transportation and industrial markets. Meritor’s technical centre is a worldwide reference point in axle production terms.

The EAS was launched on the second day of the Parma trade show by way of a technical seminar hosted by Bruno Fazzari, Moog Italiana’s Sales Manager. ‘Traditionally’, Fazzari noted during the seminar, ‘an axle is tested using two hydraulic servo actuators which work at fatigue frequency. After 2 million cycles, the axle can be approved for installation on a vehicle. The method used envisaged the use of hydraulic actuators and servo valves.

A hydraulic circuit used a power supply, pipes and so on, all subject to maintenance.’

‘The EPU is managed electronically, and allows for the implementation of a decentralized transmission system which eliminates the need for high pressure hydraulic units, extensive external piping and filtration systems. This reduces any need for additional floor space, and the risk of wear to critical components. The servo actuator is connected to the control system only by means of an electric cable, along with two signal cables for the force and position transducers’.

Arnaldo Stalla, Senior Manager for Testing and Prototype at Meritor added, ‘The market we operate in is subject to strict regulation and demands that all components, such as axles, go through very strict fatigue tests which simulate both the vehicle’s life cycle and global efficiency. Given the size of the test plants we use, it is not difficult to understand that having oil go through pressurized pipes over a distance of 40 metres incurs very high costs. Thanks to Moog’s cooperation and the development of the EPU, we succeeded in successfully solving this critical issue and ensuring increased performance, a reduction of implementation and running costs together with lower energy consumption.’

Energy savings and improved safety

There are also other advantages to the system. As Bruno Fazzari adds, ‘Even a reduction in oil consumption represents an undeniable advantage. Several types of risk, and especially that posed by fire, are eliminated at source. Today, there are only four litres of oil in Meritor’s electrohydrostatic actuators. Therefore, should a leak occur the quantity of oil that could burn is very small, and therefore any risk of a sizeable fire has been eliminated.

Clearly energy saving is also an important consideration for our customers. Fatigue tests are carried out seven days a week, 24 hours a day. With the previous actuators, energy efficiency was equal to 60%. The purchase of the two electrohydrostatic servo actuators for the new laboratory led to an energy saving which, after only 18 months, already corresponds to the amortization rate. Our clients in the testing domain are highly sensitive both to this type of saving, and to safety in the workplace”.

Moog’s focus on hybrid solutions can really make a difference, and many sectors can benefit, from the plastic industry, to die-casting and the marine industry, especially its offshore branches. In each of these sectors, reductions both to pollution levels and maintenance requirements really matter.