A New Concept of Power Transmission

Specialized in manufacturing power transmission components, the Bologna-based company Poggi Trasmissioni Meccaniche has patented P-gear®, a new way of conceiving the mechanical power transmission: no longer through traditional drive systems, but thanks to operating principles based on magnets, which reduce energy consumption, noise emissions and vibrations.

by Elena Magistretti

There’s a revolutionary concept behind the development of P-gear®, the new oilfree, gearfree technology patented by Poggi Trasmissioni Meccaniche.

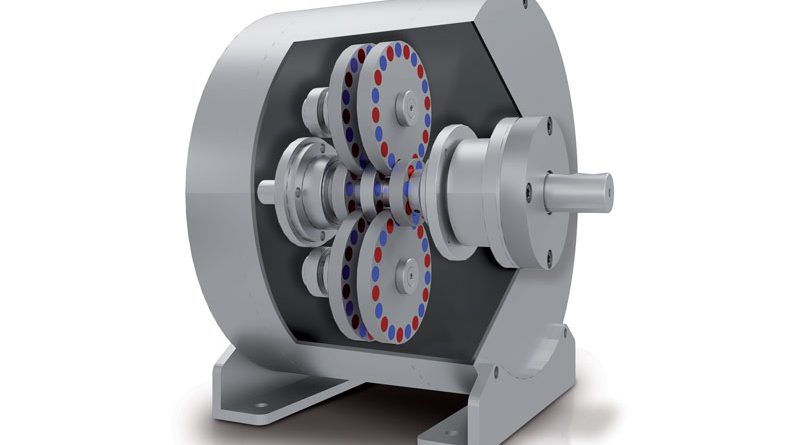

In 2017 the Bologna-based company had already launched P-drive®, a range of highly efficient, low noise pulleys and synchronous belts. With P-gear® is now presenting a transmission system with contactless meshing, with applications in the sector of right angle gearboxes and of speed reducers. This is not only a product for the power transmission market, but a cutting-edge system, which can be tailored according to customer’s requirements: a concept that can be industrialized without limits as to the fields of application. Free from gears and maintenance-free, P-gear® is an advanced, silent, clean, lubrication-free technology.

This device achieves significant energy savings and enhanced energy performances, by means of two rotors equipped with permanent magnets, which ensure transmission / speed reduction without any contact between components.

The areas of application are diversified

P-gear® can be used in a variety of industrial sectors, especially in applications requiring no lubricants, low noise and vibration levels and low risk of overheating.

The sectors of destination are the most different ones: pharmaceutical, medical, food & beverage, civil engineering, robotics in general and collaborative robotics, automation, packaging, automotive, energy, naval, oil, agriculture, constructions.

P-gear® will not compete with indstriual gear units, but offers an alternative solution but offers an ideal alternative solution to be used where there are limits in traditional uses or specific needs in terms of performance, energy savings or critical applications.

Poggi thus reduces maintenance costs, thanks to to non-contact gears free from wear and friction, and the risk of possible contamination from lubricant leakages, combining better overall performance with significant energy savings.

These characteristics make P-gear® an ideal project for obtaining research and development grants aimed at reducing environmental impact and optimizing resources.