A New Diameter for the Electric Actuator

MICROingranaggi has added a new 22-diameter electric linear actuator to its product catalogue. The component, which will be officially launched on the market before summertime, allows both high speeds and very high thrust forces to be achieved despite its small size.

MICROingranaggi has added a new 22-diameter electric linear actuator to its product catalogue. The new linear actuator available before summer 2021 has been developed starting from a solid knowledge in practical application, an aspect that should never be underestimated. As often, it is the market that gives the right inputs to companies. MICROingranaggi’s product portfolio already included a slightly larger linear actuator (32-diameter) – originally designed for furniture automation systems, later made standard and added to the company’s product catalogue.

Product customization is possible even in case of small batches

The new 22-diameter linear actuator is offered as standard with a coreless DC micro motor, but it can be customized with stepper, brushless or any other kind of motors supplied by the customer. The screw that provides the linear motion can be metric, trapezoidal or balls screw according to the needs and length required. All of MICROingranaggi’s brand products are completely designed, produced, and assembled internally. This allows the company to customize products even for small quantities. In order to meet the needs of the food industry, it will be available a stainless-steel version of this actuator and equipped with a cover to guarantee extremely high IP protection.

The improvements introduced in the new version

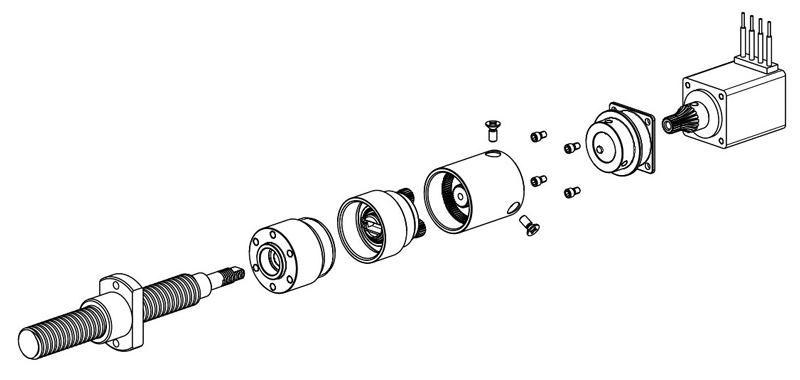

Compared to the diameter 32 linear actuator, a number of improvements have been introduced in the new component. Every linear electric actuator is made by three groups: the electric motor, the planetary gearbox and the linear actuator assembly. The improvements concern the latter, inside which are the bearings that serve to withstand the thrust. In the new 22-diameter linear actuator, extremely solid bearings have been miniaturized, which allows fast speeds as well as very high thrust forces to be obtained in relation its size. At the same time, the assembly procedures have simplified thanks to the introduction of new technical solutions. This greatly reduced the time needed for assembly and, consequently, the final cost of the actuator itself.

Electromechanical actuators: a growing market

The demand around these small electromechanical actuators is growing, because they are replacing pneumatic components in a number of applications. Reasons are many. First of all, the fact that every machinery has electric current, but not necessarily also the pneumatic one.

So, when integrating a pneumatic piston, the user is forced to have pneumatic force in the machinery. Secondly, even though an electric actuator has a higher prize then a pneumatic one, it is easier to amortize, thanks to the absence of maintenance and the low energy costs. It is also easier to program and control the speed and the positioning, making it more versatile in applications that do not only require an ON/OFF.