A single gripper for the handling of boxes and interlayers

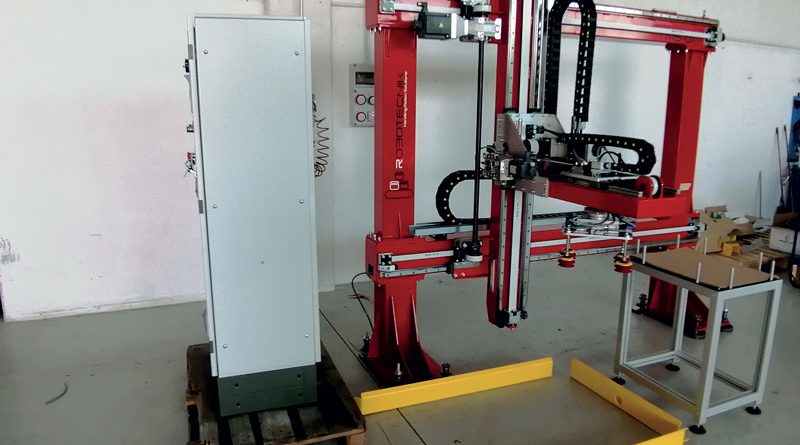

With a single gripper consisting of four B75 silicon suction cups by Piab, Robotecnik designed and manufactured a palletising robot to handle efficiently the end-of-line operations of Banca d’Italia, such as the handling of boxes and interlayers for the production of security cards. The flexibility of the system allows different types of boxes to be handled.

On a palletizing system supplied to Banca d’Italia for the handling of boxes at the production site for security cards, Robotecnik installed a gripper consisting of four B75 silicone suction cups by Piab. Each suction cup is combined with a self-supporting mini COAX® ejector by Piab for decentralised and independent vacuum generation. Each suction cup is also combined with a level compensator by Piab’s KSPH series. The level compensators are used to compensate for dimensional errors in the boxes that have a tolerance of a few mm. This is completed by a vacuum switch, also supplied by Piab, for measuring the vacuum. The operating pressure is 6 bar. Before the palletising system was installed, operations at Banca d’Italia were carried out manually by an operator. Today, the palletising robot picks up the boxes from a roller conveyor and places them on a half pallet of 800×600 mm.

The flexibility of the system allows different types of boxes to be handled. Now, three different formats are handled to meet the different dimensions of the semi-finished product. The weight of the boxes varies from 10 to 15 kg depending on the format and content of the boxes. An anti-slip interlayer is placed between every second layer of boxes. There are two pallet configurations: one with 20 boxes for the largest format, one with 40 boxes for the two smallest formats.

The gripper is the heart of the palletising system

“The gripper is the heart of the palletising system” says Davide Caretta, mechanical designer at Robotecnik, responsible for the project. “We chose the B75 silicone suction cups because they allow us to pick up both the boxes and the interlayers, which are made of a very porous plastic material that is difficult to grip. Often in palletising systems, one type of suction cup is used for the boxes and another for the interlayers. But this makes the gripper heavier and more expensive. Thanks to Piab, we were able to overcome this problem”. With the B75 silicon suction cups, Robotecnik succeeded in creating a small and flexible gripper, which fits perfectly with their Mini Open palletiser, that is appreciated for its small dimensions and because it can work at high heights. Six pallets per hour are made for pallets of 20 boxes and three pallets per hour for pallets of 40 boxes. In fact, the palletising system takes about 30 seconds per box because Banca d’Italia does not need any particular speed, but a continuous and constant process.

The palletising robot could go much faster and pick up a box every 10 seconds or make 6 cycles per minute with a single grip. Suction cups for multi-purpose applications, where height compensation is required Piab’s B75 silicone suction cups are developed for multi-purpose applications, where a certain height compensation is required. The high-quality silicone they are made of is not usually the choice for handling cardboard boxes, but thanks to its softness it can solve handling problems or particularly low or high temperatures. Piab’s COAX® vacuum generation technology minimises energy consumption while offering a safe and fast grip, thanks to its high initial flow rate. The pump unit can deliver high performance even with low or fluctuating supply pressure. This has been proven in independent comparative tests conducted by the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Dresden. These tests showed that Piab ejectors require significantly less compressed air to achieve the same result as ejectors from other suppliers. Consequently, their use reduces the cost of compressed air supply and thus the total cost of production.