A Specially Designed Gearbox Guides You To Victory

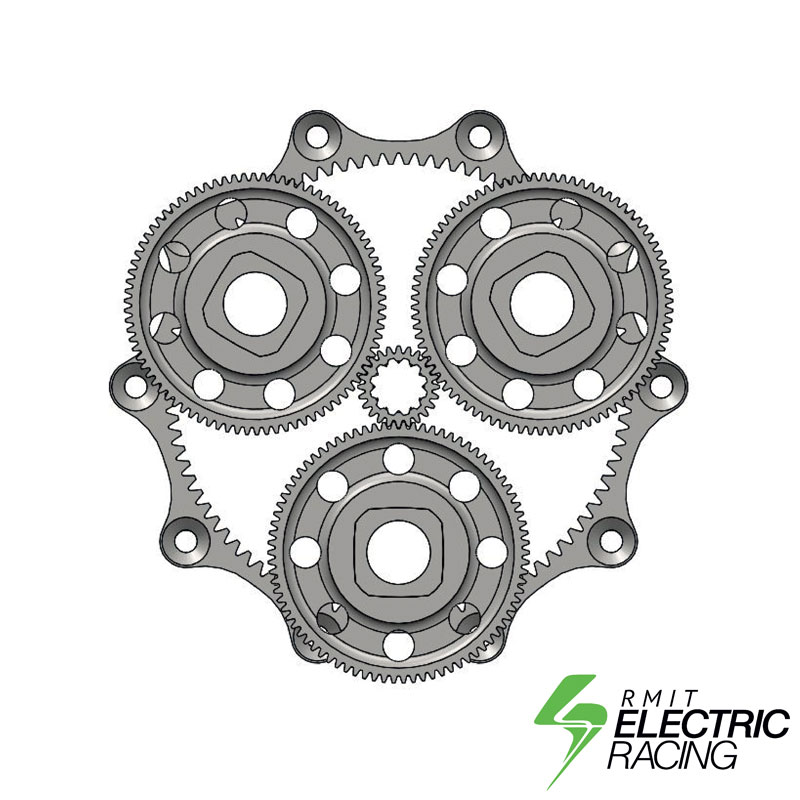

RMIT Electric Racing has been producing electric vehicles since 2008. A part of the success and the progress of the team is owed to KISSsoft. Apart from the electronics, the powertrain is one of the most important parts of the vehicle and KISSsoft has significantly contributed to its success. With the help of KISSsoft, the team has been able to meet its vehicle requirements and design a compact and ultra-lightweight compound planetary gearbox with the required torque.

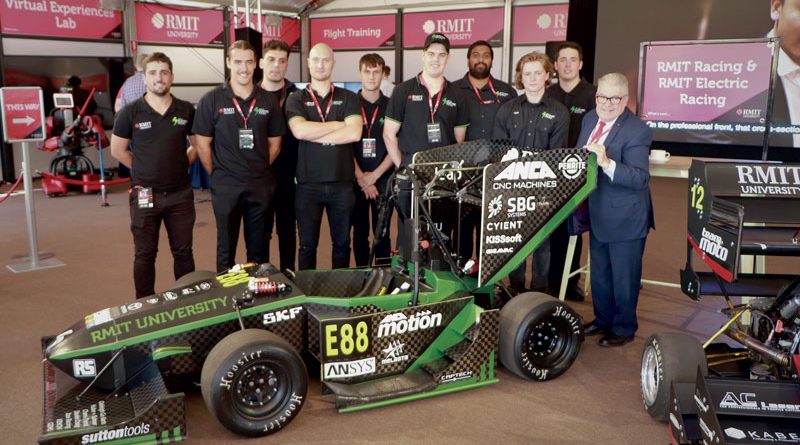

RMIT Electric Racing is an organisation run and operated by students that promotes education, innovation, and community through the development of a full electric vehicle for the Formula Student competitions. The team comprises of over 50 passionate students from over a dozen facilities at RMIT University, which work committed to their project gaining knowledge and experience for their professional career.

The team, the vehicle and their progress

RMIT Electric Racing has been producing electric vehicles since 2008, when the first Student EV was created to show FSAE that there was room for environmental-friendly solutions. During 2019, the team was able to perform highly in the Australian events, achieving 1st in all EV events in the FS-Sydney Competition in early 2020. As such, the team was preparing to go to Europe during 2020 and compete in FSG (Formula Student Germany), before the Covid-19 pandemic in 2020 cancelled their plans. However, the members of the team have hopes in going to Europe in the future years.

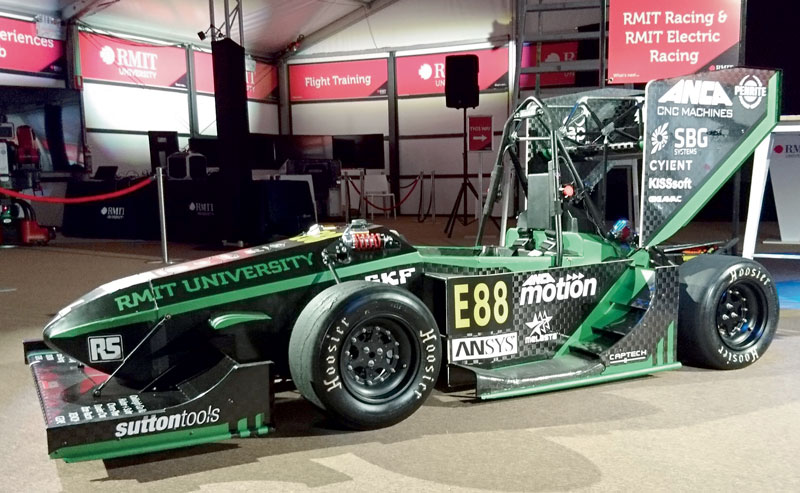

The team consists of a large diverse group of undergraduate students from mechanical engineers to electrical engineers, computer science and business marketing students. Such a group enables the team to design custom and test all the vehicle’s components, to achieve the best results on the racecourse. The vehicles’ HV and LV system has a large portion of student custom designed circuit boards enabling better packaging of the components leading to lower vehicle weight and as importantly – better accessibility and serviceability. Part of the HV System is the accumulator at the rear of the vehicle. The team is fortunate enough to have a spare accumulator that is interchanged with the first one when the capacity is exhausted. The two accumulators enable the team to do interesting strategies that keep the vehicle performing to the designed limit. Apart from the 144 Li-po cells, the whole accumulator is custom-designed and built – including the housing and BMS.

Calculation software helps powertrain upgrading

A part of the success and the progress of the team is owed to KISSsoft. Apart from the electronics, the powertrain is one of the most important parts of the vehicle and KISSsoft has significantly contributed to its success. KISSsoft has enabled the team to upgrade the powertrain and final drive package to keep up with the other formula student teams all around the world. To reduce our lap-times, the vehicles torque was increased with 4 in-wheel hub motors to achieve 4WD. However, since the in-wheel hub motor needs a speed reduction, an in-wheel gearbox is needed. As these components are unsprung , the reduction of the size and weight are very important for the overall performance. The size of the gearbox is also crucial, as the gearbox is space-constrained within the suspension a-arms, chosen wheel bearings, brake disc and brake calliper. With the help of KISSsoft, the team has been able to meet its vehicle requirements and design a compact and ultra-lightweight compound planetary gearbox with the required torque. The designing of this gearbox was made a smooth experience as the team was able to easily sort through thousands of gearboxes to attain the one that meets the requirements. KISSsoft provides lots of tutorial videos and lessons that helped the team understand how to use the program. KISSsoft also enables the members of the team to be confident in their designs as they are able to estimate the predicted cycles/ hours of the gearset, design optimized shafts and export this data in a nicely formatted technical engineering report for documentation and presentation. A further example was the planet shaft for the gearset; with the help of KISSsys, they were able to choose lightweight and life-cycle dimensioned bearings and run calculations to find the equivalent maximum stress which we could then validate using FEA programs. This geometry would then be exported to our 3D modelling program to be added to the 3D assembly of the drivetrain system. This all would then be exported as engineering drawings and with the help of the KISSsoft calculation programs, they could also easily export manufacturing friendly files and diagrams. As KISSsoft is widely used in the engineering industry, it also helped the team communicate its ideas with these professionals. The support and the contribution of KISSsoft has been of great importance to the members of RMIT Electric Racing and their future careers. l

About the author: Stewart Marrogi is Drivetrain System Head at RMIT Electric Racing.