A Stronger Position in the Belt Conveyor Market

In the Hybrid Belts series all the advantages of timing belts and conveyor belts are gathered in one product, optimally combining the quality of both components. With the Spiraflex series Megadyne offers a range of belt conveyors for the food industry. Both series are now part of Megadyne’s offer thanks to the acquisition of the company SACIF.

by Alma Castiglioni

The Megadyne group, in over 60 years of experience, starting as a single-product manufacturer has become a multinational company specialized in power transmission tools, progressively expanding its business to strengthen its market position. The acquisition of the company SACIF, a specialist in the field of reworking belts and conveyor belts, is in line with this strategy of completing the production range and allows Megadyne to propose the Hybrid Belt series (basic version, Hybrid Belt Plus, Hybrid Pro Belt Plus and Hybrid Belt For Vacuum). These belts are used for packaging, food and medical, paper and printing industries, robotics and automation.

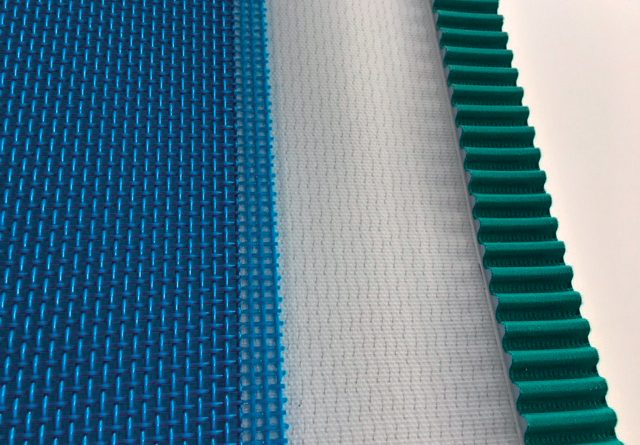

These innovative hybrid belts presenting unique characteristics on the market are made with the application of one or more polyurethane timing belts in the central part (or at the edges) of a conveyor belt, optimally combining the qualities of both products.

A range of hybrid convetors with integrated toothed belts

The Hybrid Belts series operates in a wide temperature range (-20°C/+ 80°C for Hybrid Belt and Hybrid Belt Plus; -25°C/+ 80°C for the top of the range, Hybrid Pro Belt Plus) and ensures greater productivity, with a driven speed up to 550 meters per minute even in case of customization. The lower energy absorption (about 30%), combined with a quick and economical retrofit on to existing systems, lead to further savings while the smaller pulleys allow a compact transmission and greater flexibility.

The timing belts used to make Hybrid Belts and Hybrid Belt Plus are Megalinear: the pitches commonly used are T10, T5, H, HTD5M, HTD8M, STD8M.

Whereas Hybrid Pro Belt Plus mounts the Megalinear QST that guarantees less noise. Finally, Hybrid Belt For Vacuum is the ideal solution for automation and vacuum handling due to the addition of a polyester plain fabric that guarantees optimal suction.

Customized open mesh conveyors for the food industry

The Spiraflex series, now part of Megadyne’s portfolio of conveyors thanks to the acquisition of the SACIF company, includes open mesh conveyor belts manufactured and packaged in Italy, are specifically designed for the transport of food products and for hygiene products. Spiraflex conveyors are made with food contact approved materials and in full compliance with the hygiene rules that regulate food processing and manufacture. The belt edges are sealed to ensure that the belts integrity is maintained, during operation and aggressive cleaning regimes. Spiraflex is a safe and reliable product, reducing any risk of product contamination due to our specialised fabrication techniques. It is lighter, higher performance product, compared to conveyor belts with a metal mesh. Spiraflex offers an excellent performance, at a range of temperature between -30° and +90°. l