A Way to Increase the Effectiveness of the Overall System

By monitoring the tribological conditions of linear guidance systems, basing on vibration signals, Schaeffler DuraSense increases the effectiveness of the overall system. DuraSense consists of carriages with sensors and a pre-processing unit that provides information about the entire lubrication system and acts as needed.

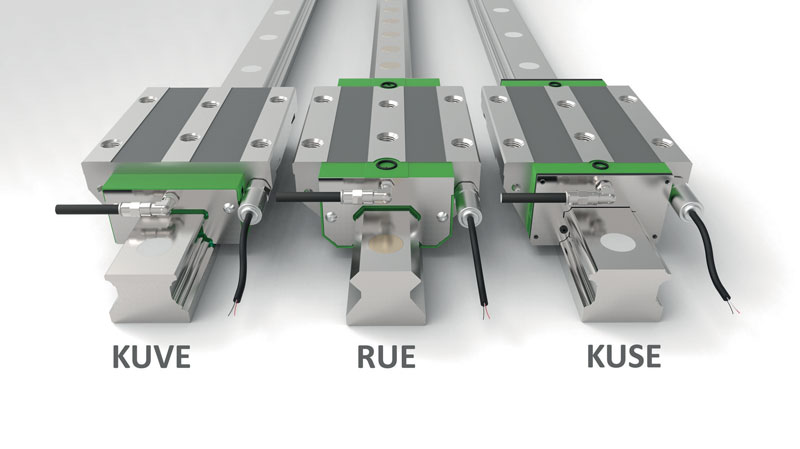

Schaeffler DuraSense is designed for the safe operation of INA linear recirculating ball or roller bearing and guideway assemblies and monitors the tribological conditions of linear guidance systems based on vibration signals. The system comprises carriages with sensors developed specifically for this task and a pre-processing unit for up to seven sensors. The pre-processing unit is at the heart of DuraSense and contains Schaeffler’s rolling bearing expertise, evaluates the sensor signals, and generates an authoritative parameter, the lubrication parameter.

The vibration energy that is emitted by the carriage is affected as the lubricant ages or the quantity of lubricant becomes less, and the Schaeffler DuraSense makes use of this effect. The lubrication parameter measured during measurement runs describes the carriage’s current lubrication condition and Dura Sense sends a signal to the machine’s control system if a lubrication limit value generated based on the bearing’s new condition (i.e. the target situation) is exceeded. As an option, Schaeffler DuraSense can be combined with a lubrication system from Schaeffler (Concept2 or Concept8). Schaeffler DuraSense provides various options for increasing the effectiveness of the overall system depending on the application.

Schaeffler DuraSense can detect both correct relubrication and insufficient relubrication. An unforeseeable and premature machine downtime caused by insufficient lubrication or a failure to perform relubrication and maintenance. .A service setup tool is used for configuration and initial operation. For this purpose, the pre-processing unit is connected to a PC via an ethernet interface. The lubrication condition and the lubrication limit value are measured and displayed during a subsequent reference run with a freshly lubricated carriage. The log files for the measurements can be read out and updates loaded via the ethernet interface if required.

Lubrication condition as an analog or digital signal

The pre-processing unit can transmit digital signals 0 – 24V or analog signals 420 mA to the machine’s control system. The digital signal indicates whether the lubrication condition of the carriage corresponds to the target situation or whether relubrication is required. The analog signal enables a differentiated analysis of the lubrication condition and provides the option of using the lubrication parameter for further more detailed analyses.

Schaeffler DuraSense makes the lubrication condition of the carriage transparent and indicates critical lubrication levels. This enables a conversion to manual lubrication in linear axes, which e.g. are only connected to a central lubrication system for safety reasons due to low loads and short periods of operation. The machine layout is thereby simplified and the costs for the pipework connection to the central lubrication system including the metering valve can be saved. Overgreasing or an accumulation of grease and the risk of contaminated workpieces – a common phenomenon when central lubrication systems are used – can also be prevented.

Since Schaeffler DuraSense monitors the changes in the lubrication condition on the carriage, the system detects all the defects and changes that can affect lubrication. This includes all defects in the lubrication system and defective guidance system covers and the influence of cooling lubricants etc. Schaeffler DuraSense notifies the control system that relubrication is required before the next, defined lubrication interval. This enables a troubleshooting function in the event of unusually short relubrication intervals. In highly automated manufacturing systems with considerable interlinking of machines, entire production lines can be protected against unplanned downtimes in this way, which significantly increases the effectiveness of the overall system.