Accurate Measurements with the Magnetostrictive Technology

With HYPERWAVE Gefran presents a detection system which is capable of ensuring a repeatability of 0.01 mm with a very low non-linearity error of 0.01%/FS and a resolution of less than 0.5 µm, also operating at extreme temperatures from -30° C to + 90° C. The amplification of the primary element’s signal, 15 times greater than traditional models, makes the contactless transducer immune to the typical industry electromagnetic fields, guaranteeing precise and continuous operation over time. In detail, HYPERWAVE boasts a high tolerance to vibrations (15g/ 10 ÷ 20,000 Hz) and to shocks (100g – 11ms – single strike). Finally, the waterproof case ensures an IP67 level of protection, contributing to make this system ideal for use in harsh industrial environments.

The long working lifetime and the reduced maintenance are among the strengths of the new Gefran solution compared to traditional measurement systems. By virtue of the magnetostrictive technology, the position is identified by the interaction between two magnetic fields: the first is electrically generated along the entire transducer and it interacts with the second, consisting of a cursor – with a sliding or floating design – equipped with a permanent magnet. The elimination of mechanical contact makes the system nearly immune to wear, thus significantly reducing downtimes.

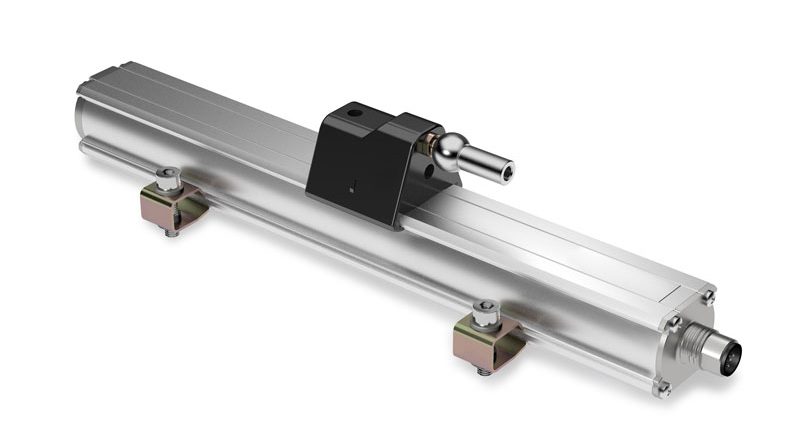

The complete range consists of two macro-categories: WP (Profile Magnetostrictive Position Transducer) with profile mechanics mounted with brackets directly on the structure to be measured, and WR (Rod-style Magnetostrictive Position Transducer) with 10 mm rod mechanics in AISI 316L stainless steel, that are mainly installed inside hydraulic cylinders with operating pressures up to 350 bar, to detect the position of the piston in real time. Transducers with WR rods can also be used as tank level meters, thanks to the magnetic float cursor.

Thanks to its precision, reliability, robust and compact design, this solution can be used in various fields of application, including injection moulding, robotics, hydraulic presses, foundries, die-casting and wind generators.