All the Highlights of the New Release

Several innovations have been introduced in the new KISSsoft 2020 Release, among which are additional methods for reliability assessment of the gearbox concept, changes of the calculated safety factors, the extension of the programming language (scripting) and the integration of FEM calculations.

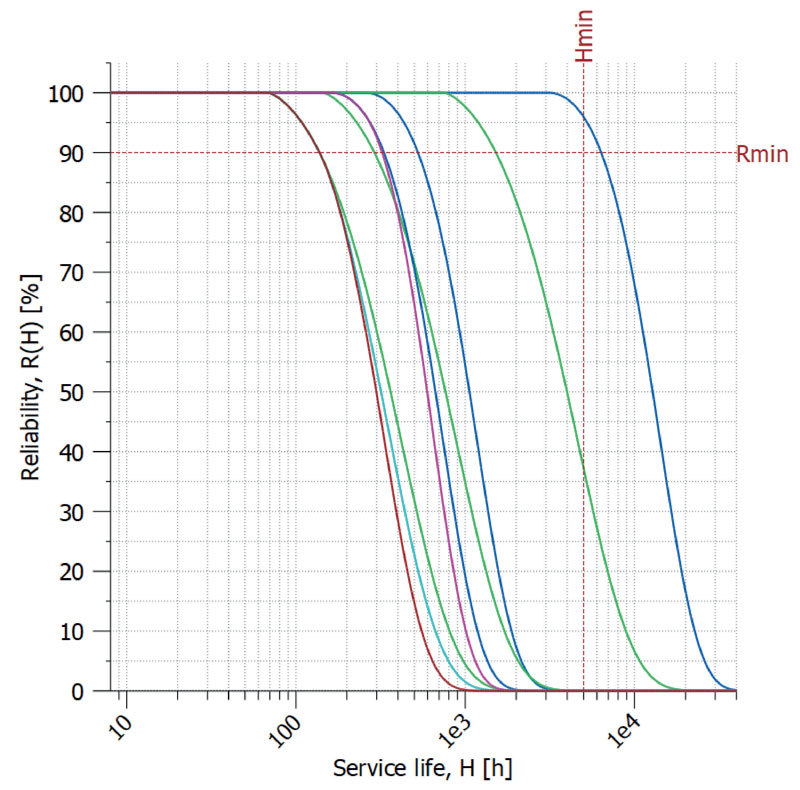

Reliability Assessment of the gearbox concept is among the many improvements introduced by KISSsoft 2020. In addition to safety factors, results are increasingly extended with a time-dependent probability of survival or required reliability. In addition to the Bertsche calculation method, AGMA 6006 and VDM 23904 are now also available. The calculation procedure is available for individual damage mechanisms, components, subsystems and entire gearboxes. This makes it possible, for example, to create maintenance plans, optimize spare parts inventory or even compare two gearbox designs with a holistic approach. Compared to the previous version, changes of the calculated safety factors have been also introduced. Such changes, in some cases considerable, will influence the future design of gearboxes and the minimum safety factors required by certification guidelines.

The integrated programming language has been extended

The integrated programming language has been extended for tailor-made calculations. Thanks to the KISSsoft-”Script”, calculation automations and event functions (preCalc, postCalc, etc) can be programmed independently and individually. Typical applications are, for example, tolerance analyses, integration of company-specific research methods, individual interfaces and much more. The efficient and easy-to-learn programming language “Script” is available in all KISSsoft modules.

Format for gearbox data exchange

VDI/VDE 2610 defines a format for the exchange of gear data. Gear Data Exchange Format (GDE format) enables digital transmission of gear data between design, production, measurement and quality inspection. The GDE (Version 2.6) export and import is available in KISSsoft from Release 2020 and includes the micro and macro geometry of spur and helical gears.

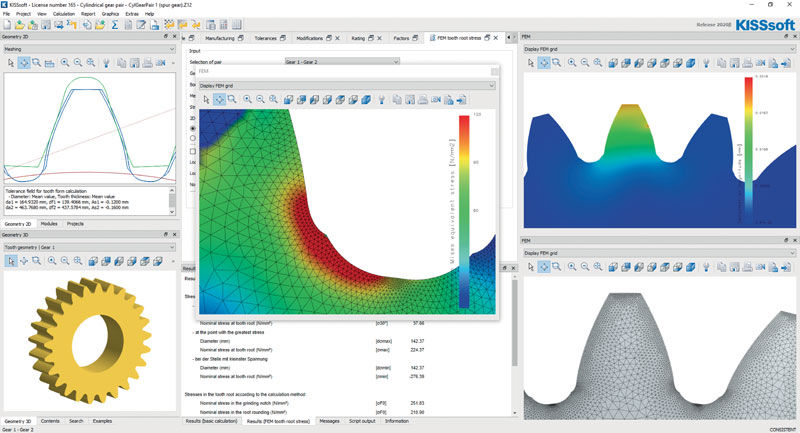

Results of the FEM calculations are integrated in the software

The results of the FEM calculations of the gear body deformation as well as the 2D and 3D tooth root stresses are now additionally displayed in KISSsoft.

For the user, this means a significantly faster evaluation of critical components and critical points as well as better control over the calculation than before. The usual graphics such as meshing, deformation, as well as the stress according to von Mises and other graphics are available for evaluation.

For a detailed evaluation, post-processing with SALOME is still recommended. This also shows the trend and the long-term strategy of KISSsoft to further advance the integration of FE calculations in their calculation programs.