Automating intralogistics at various levels

Bonfiglioli approaches the AGV market with dedicated taylor made solutions. The AGV System platform, in particular, includes three configurations featuring different levels of integration: Base, Advanced and Compact in order to suit the automation requirements of an intralogistics system.

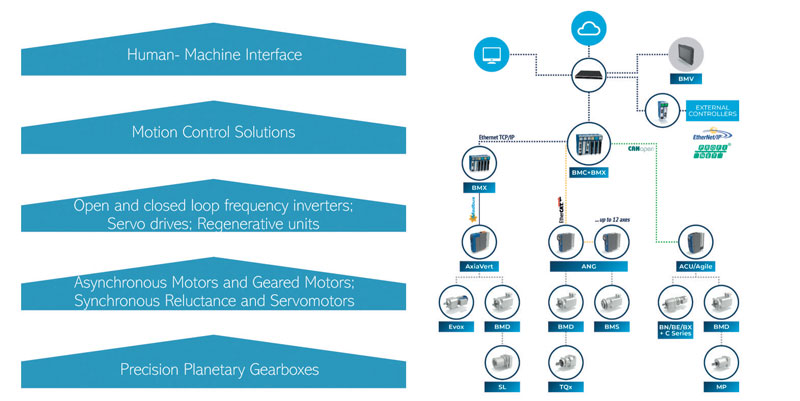

Intralogistics requires various types of equipment and machinery, such as automated storage systems, warehouse vehicles and many others. Thanks to decades of experience in designing complete solutions for specific applications, Bonfiglioli can offer the most suitable product for material handling, transport and storage applications: solutions characterized by efficiency, reliability, flexibility, load capacity and environmental compatibility.

Automated guided vehicles: a fast-growing market

Automated Guided Vehicles (AGVs) or transportation robots, are driverless, computer-controlled material-handling vehicles. These vehicles are programmed to transport materials through designated pickup and delivery routines within a facility. AGV industry has registered a very strong growth in the latest years. This technology is increasingly adopted due to numerous advantages: shorter & faster product cycles, increased needs for manufacturing flexibility, increased ergonomic and safety, reduced labour costs, increased accuracy and productivity, easily expandable layout and system capacity, enhances workplace safety by eliminating related accidents caused by human error, perform tasks in dangerous environment

such as handling hazardous substances, working in extreme temperatures and moving heavy materials. Companies continue to invest in automation, and in many cases AGVs are the most suitable solutions. Mobile robots are met in many sectors such as: logistic, pharmaceutical, automotive, and even more. Bonfiglioli has oriented its offer to the deck load solutions being those that better respond to the most innovative design concept and the most technological one.

The innovate AGV platform includes three levels of integration

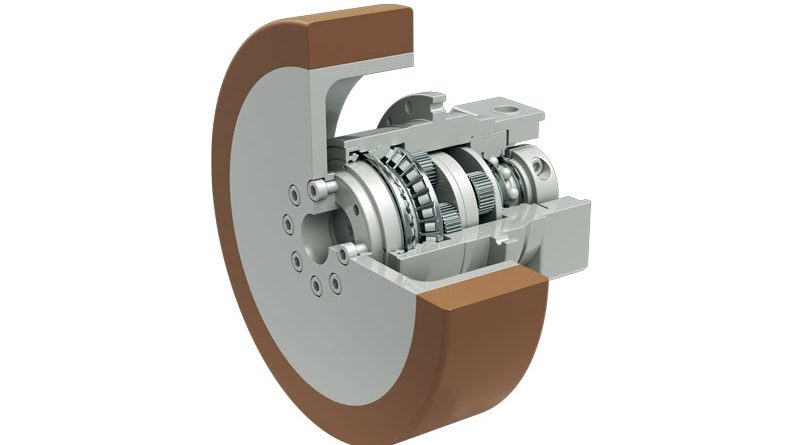

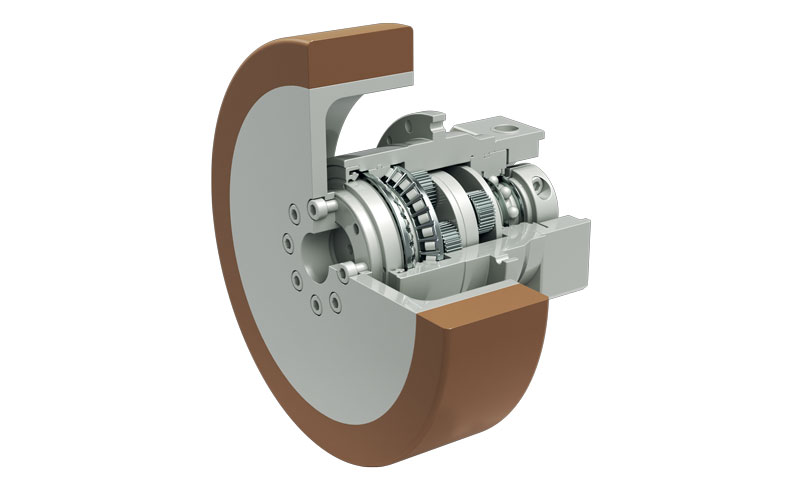

Bonfiglioli’s solutions for AGV systems are the answer to a continuously growing sector characterized by challenging requirements. By relying on our expertise and by working in close synergy with their partners, the company has developed a number of AGV’s solutions over the past few years. The result is an innovative technological platform, including three levels of integration. The Base version consists of a flanged version planetary gearbox with high-capacity load support and wheel integration. Bonfiglioli has developed an extremely compact solution with a design concept that allow the gearbox to be integrated inside the wheel reducing drastically the axial dimensions. The gearbox is integrated inside the wheel. This lead to an extreme compactness and a high load capacity because the disposal of the radial load and highest load capacity bearings extend the lifetime of the product and load to carry. In the design phase a thermal effectively characterisation was considered versus traditional solutions; seals and lubrication have been optimized too, making it possible to obtain longer cycles and higher loads. Bonfiglioli’s offer comprises 3 sizes for load capacity in the 350 – 1000 kg range, speeds up to 2m/s and positioning 0,2 … 0,3 mm. An even more precise positioning can be achieved by reducing the backlash of the gearbox.

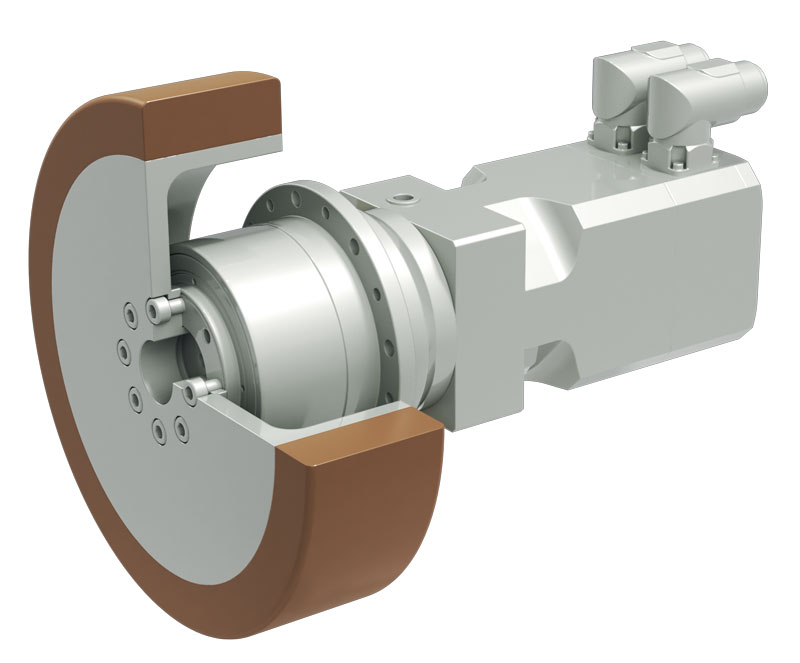

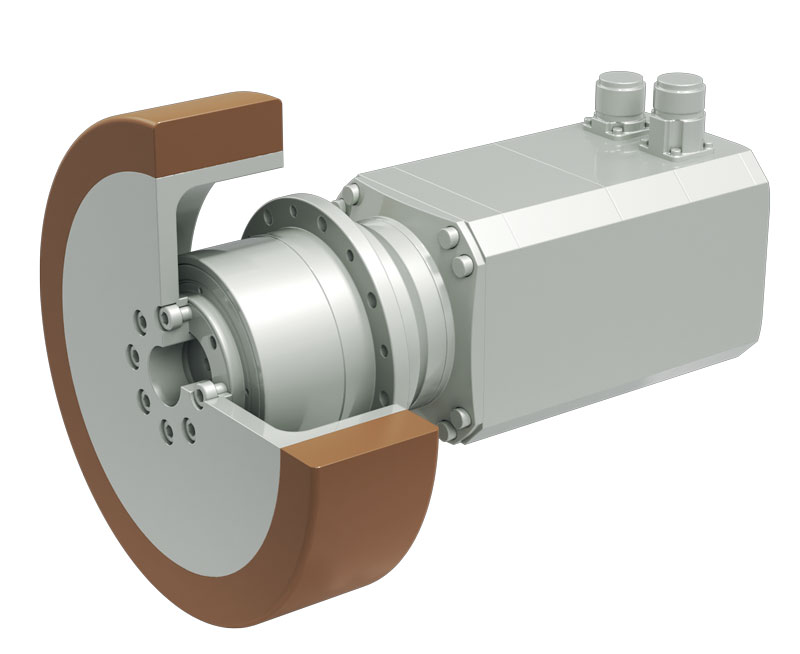

The Advanced version includes a low voltage brushless motors for battery systems (typically 48 V / 24V) from Bonfiglioli. Thanks to the company’s know how and a high level of customization Bonfiglioli can offer: extended motor – torque dominium for the motors, high compact encoders with various protocols, different type and layouts of the connectors, parking or dynamic brakes systems, high IP protection and much more… The Compact version represents the maximum expression of compactness and performance. Indeed, motor and gearbox are integrated together not with a typical PAM flange. Sun gear is mounted directly to the motor shaft and gear together with the first gearbox stage. This led to a reduction of axial layout up to 25%. Bonfiglioli’s designers have selected the motor combination that can lead to maximum output and characterisation and at the same time the straightest layout. l