Bearings Maximize Efficiency in Woodworking

NSK bearings and its AIP Added Value Programme help woodworking machine builders make considerable savings. In the two case studies described in these pages two types of bearings were chosen: NSK spherical roller bearings for the vibrating screen and NSK pulley bearings. In both cases NSK bearings proved to be the right choice to withstand the harsh operating conditions such as those found in woodworking shops.

by Alma Castiglioni

Shock loads and vibration are common issues for woodworking machinery that can impact on the overall performance of bearings. Faced with premature bearing failures every 2-3 months, a manufacturer of MDF boards called upon the expertise of NSK and its AIP Added Value Programme. The plant set a target of at least one year bearing lifetime, which would allow it to only perform planned shutdowns and maintenance. NSK’s specialist engineers commenced a full application review, meticulously studying the design of the grinding machine and its operating conditions. As a result of its observations, which identified the cause of bearing failures as shock loads and vibration, NSK recommended installing its special vibrating screen series of spherical roller bearings, which were provided for testing. The conclusion of the trials saw bearing lifetime extended to 10,000 hours, which met the expectations of the MDF plant. The previous cost of €13,400 per year associated with downtime and bearing consumption, was therefore eliminated.

After 14 months of operation, the NSK bearings were replaced as part of a planned maintenance routine.

Excellent capacity to withstand harsh working conditions

NSK’s long-life vibrating screen series of spherical roller bearings are engineered to withstand harsh working environments, particularly those where recurring vibration is an issue.

The bearings are supplied with a precision machined, tough, one-piece brass cage. Further features include high levels of surface finish on the rollers and inner/outer rings, and especially heat treated rollers to prevent cracks from vibration and shock loads.

As a result of these characteristics, NSK’s vibrating screen series of spherical roller bearings offer at least twice the service life of conventional bearings, while dynamic and static load ratings are increased by 1.25 times. The bearings can be supplied in bore diameters from 40 to 200mm.

The right bearing for a safe table guidance

After suffering repeated failures of its table guide rollers, an international woodworking machine manufacturer called upon the expertise of NSK and its AIP Added Value Programme to resolve the issue. The decision proved lucrative, with NSK helping the company to save a total of €13,333 per annum in reduced labour and assembly costs.

Upon arriving at the customer’s facility, NSK set about investigating the problem with the table guides, discovering that the existing bearings had insufficient tolerance. This issue, in combination with inconsistent bearing assembly methods, was resulting in the frequent failures.

A proposal was made to adopt NSK pulley bearings, predominantly because of their higher tolerance levels. In tandem with a suitable NSK training course that allowed consistent table guide assembly, it was calculated that the problem would be resolved. Sure enough, these actions enabled fault-free running of the machine and reduced fitting times for the bearings.

Sealed bearings provide protection against dirt and other contaminants

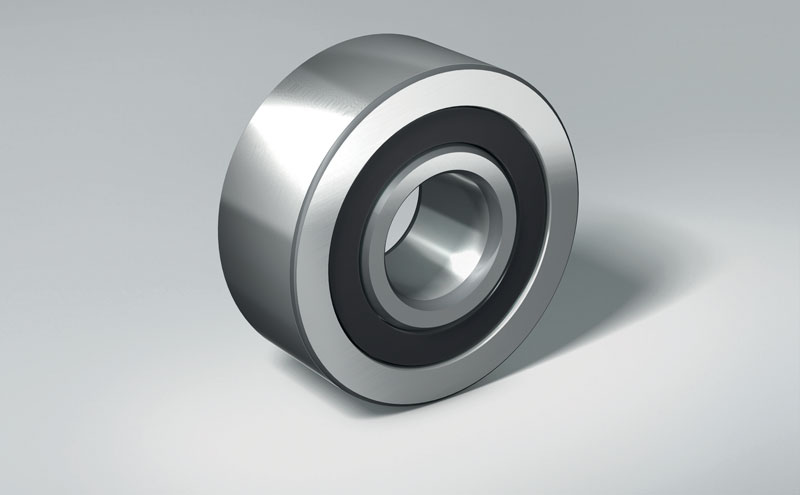

Pulley bearings from NSK correspond in design to a sealed double-row angular contact bearing.

Based on their function as pulley bearings, the outer ring – which can be cylindrical or crowned – is reinforced.

Importantly, in harsh operating conditions such as those found in woodworking shops, NSK pulley bearings feature contact seals that provide excellent protection against the ingress of dirt and other types of contamination. These bearings also serve to reduce wear on the raceways and ball surface, cut noise levels, and reduce vibration and the danger of lubricant failure.

A further advantage of NSK pulley bearings, which accommodate radial and axial forces in both directions, is their potential to be re-greased through the inner ring.

At the woodworking machine manufacturer, NSK pulley bearings were subjected to an initial trial, which demonstrated their superior performance, without any failures. In tandem with employee training in bearing installation and removal, it was possible to reduce assembly costs and staff deployment.