Calculating hob cutting time and speed in gear production

In gear manufacturing there are variables that should not be underestimated. Two of these are speed and cutting time in gear hobbing. Let us see how they can be calculated and how these parameters can affect the final cost of the gear.

There are many parameters that influence the final cost of a mechanical component. Parameters that are often not easy to understand, especially for professionals who do not have in-depth technical knowledge of machining. This is the case, for example, with gear hobbing, where the helical tool creates the external teeth of the gear through a series of passes. This article looks at some aspects of this machining process and, in particular, cutting time and speed in gear hobbing.

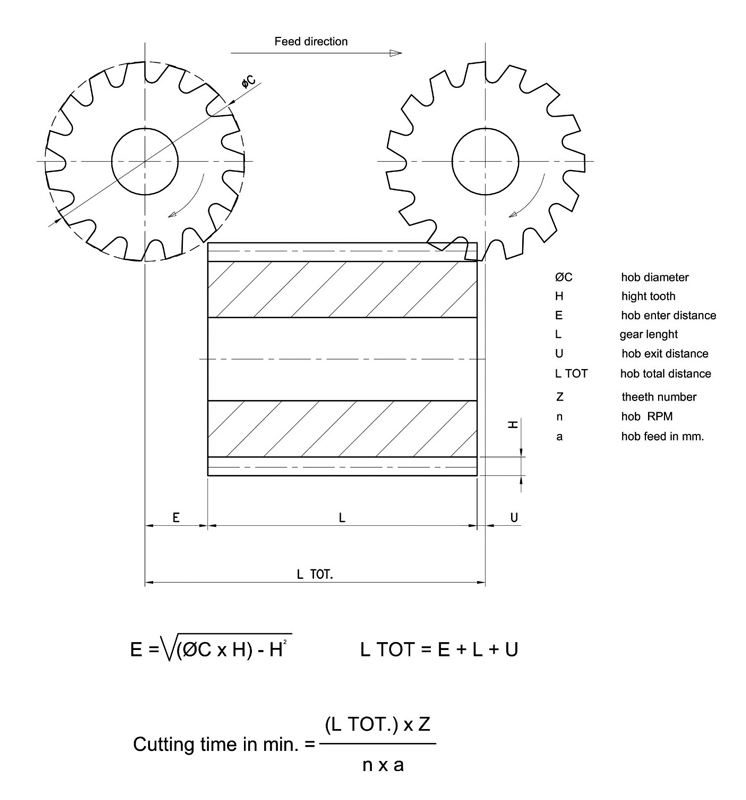

Calculating a gear hob cutting time

The cutting time is the first variable we will deal with. The diagram shown in picture 1 provides a simplified representation of a hob and a starting point, with the uncertainties relating to the rpm (hence the cutting speed) and the forward feed rate. These parameters depend on many different factors, such as: the quality level required for the order; the gear material; the hob tool type (material, number of sharp edges, coating etc.); the shape of the gear and the position of the teeth; the rigidity of the clamping equipment; the rigidity and power of the gear hobbing machine. A more detailed explanation is provided by Stefano Garavaglia, CEO of MICROingranaggi, a specialist in the design and manufacture of small and very small gears and, more generally, of precision mechanical and electromechanical micro-components. “The diagram illustrates the length of the tool stroke on the numerator, which clearly shows that the evaluation of the tooth length is a fundamental cost item during the design and engineering phase. Likewise, the tooth height (hence indirectly the module) and the tool diameter, both in the numerator, have a direct impact on production times. We can therefore say that halving the number of teeth and/or the tooth length means halving the production time. The denominator however shows the result of the rpm for the forward feed rate. This means therefore that the tool, the rigidity of the equipment and that of the machine are all fundamental cost items. In addition to these factors, we will then need to add the machine loading and unloading time for each piece, which will require from 4 to 15 seconds for large batches as this process will operate in automatic mode, or a minimum of 15/20 seconds for the smaller batches which will presumably be operated in manual mode. Generally speaking we then consider a 55 minute hour for an automated productive process, (it is in fact necessary to reserve time for tool grinding, the cleaning of tanks and so forth), and a 50 minute hour for a manual load process (given the need to also take into account the physiological breaks required by an operator). Upon establishing all these variables, we can now deduct that a gear cutting time can be “X”, but also “2X”, or “1/2X”. However, establishing the price of this process is even more complicated, since this aspect is also influenced by other factors such as the services provided by the supplier, its guarantee regarding the quality and reliability of the finished piece, general expenses and the added value that the supplier is able to provide regarding its work.

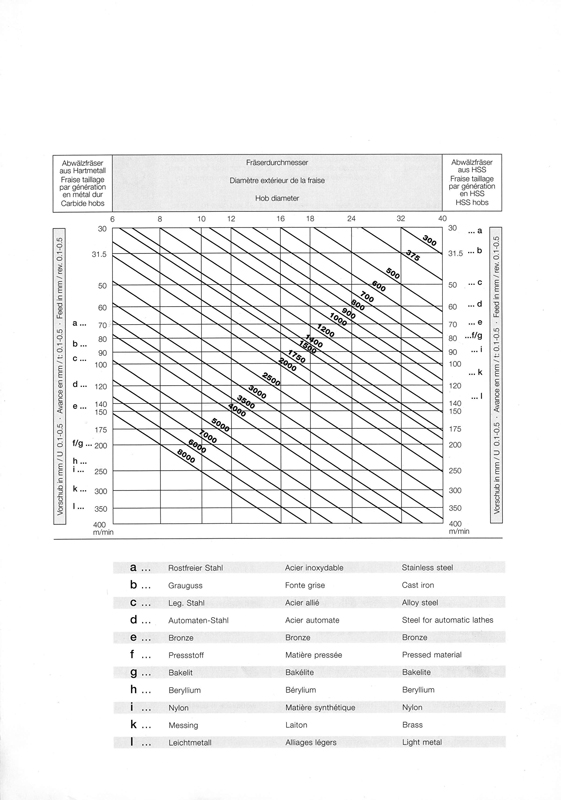

Defining the correct cutting speed

If the cutting time can be deduced by taking certain variables into account, the question also arises as to the cutting parameters depending on the tool and the material to be machined. In other words, what is the correct cutting speed in gear hobbing? The table shown in figure 2 (drawn up and published by the Swiss company SMH AUTOMATION) may be of help, bearing in mind that the limits shown are related to the diameter of the tools used by the Swiss manufacturer, precisely because the diagram refers to its product range. “The chart in question – Garavaglia explains – does not envisage variations due to any PVD coatings; it refers solely to the use of single start hobs; and only considers the number of standard cutting edges based on the hob diameter. Though reliable, these data are to be considered purely indicative. Given that hobs are finishing tools, hobbing speeds can be significantly increased during pre-grinding roughing cycles. Furthermore, at a practical level, the hobbing speed should also be adapted to suit other parameters such as the shape of the workpiece, the rigidity of the equipment, the power of the gear hobbing machine and, most importantly, the level of quality required by the technical specifications. In conclusion, I would say that the supplier who is able to calculate the best possible time according to product and customer requirements will get the most orders”.