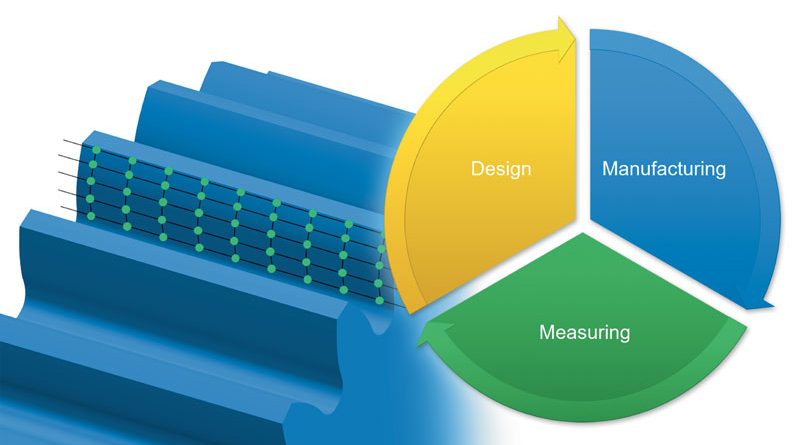

Design/Manufacturing Closed-Loop for Cylindrical Gears

The “Design/Manufacturing Closed-Loop” for cylindrical gears developed by KISSsoft allows the design to be modified to match a manufacturing process – or the manufacturing process can be tested for suitability to achieve the desired transmission performance at the lowest cost. This way, design, manufacturing and measurement are integrated into one holistic process.

“Closed-Loop” is a term used in state-of-the-art bevel gear manufacturing, but has not been widely used – at least not as a term – in the cylindrical gear world. The “Closed-Loop” in manufacturing aims at minimizing manufacturing deviations by using evaluation software to determine the necessary correction values for the adjustment of the production machine. This optimizes the manufacturing process so that the manufactured parts achieve the specified accuracy. In the “Design/Manufacturing Closed-Loop” for cylindrical gears developed by KISSsoft, a feedback of the manufacturing deviations to the desired properties of the design (e.g. NVH behavior under load) is performed. If the cumulative deviations are too high, the manufacturing must take measures or a reject selection must be made. This analysis can be performed with the help of KISSsoft calculations.

Functional evaluation of manufacturing deviations

First, gears are designed in the design process according to the desired criteria. After manufacturing, the tooth flank geometries of milled or ground gears are measured, for example on a Gleason measuring machine, and fed back into the KISSsoft program. With the measured tooth flanks, important performance criteria in the drive train – e.g. contact pattern, NVH behavior or service life – are recalculated. The simulation results can then be compared with the design results and allow a functional evaluation of manufacturing deviations in the system.