Connectivity at the Forefront in Measurement Systems

Heidenhain’s presence at SPS IPC Drives 2018, Nurnberg, was focused on connectivity. Regardless of the application in which its products are to be used, the available mechanical and electronic connection options between individual components and within complex networks are both manifold and convenient.

by Andrea Baty

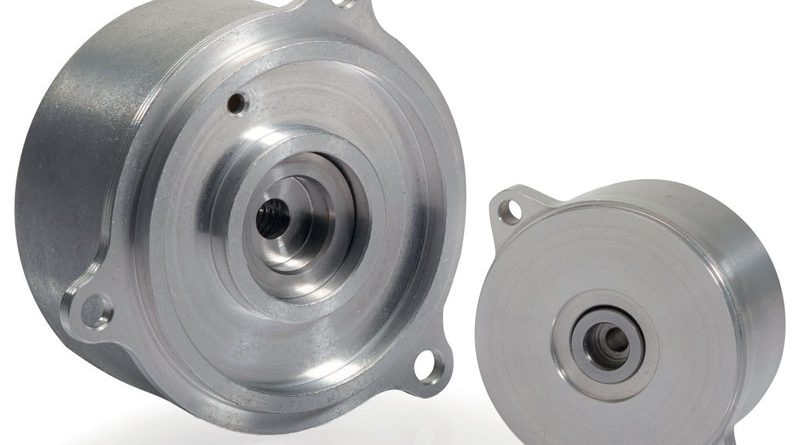

Position measurement tasks require encoders that are capable of fulfilling a variety of requirements. These include not only accuracy and reliability but also mechanical and electronic connectivity. For both accurate and highly accurate applications, Heidenhain offers a broad spectrum of encoders. Their wide variety of interfaces and identical mounting dimensions provide machine and equipment manufacturers with a standardized design that is independent of the subsequent electronics used. Linear, angle, and rotary encoders are available with serial interfaces to common controls, including those of Heidenhain, Siemens, Bosch, Fanuc, Panasonic, Mitsubishi, Yaskawa, and many more. Encoders that are explicitly certified for safety-related applications, such as the ECI and EQI series rotary encoders, are well suited to the task of providing servomotor feedback on safe axes. These encoders fulfill the requirements for safety-related applications up to SIL 3 (EN 61508) or PL d (EN ISO 13849).A key advantage of serial interfaces is their diagnostic functionality. Such functionality supports the analysis of complex machines, thereby providing an important contribution to the topic of Industry 4.0. Heidenhain makes diagnostics much easier through the use of valuation numbers, which enable the assessment of an encoder’s function reserve. The high level of expertise formerly required for the evaluation of encoder signals is no longer necessary. This superior approach is also available with other interfaces besides EnDat.

Heidenhain is the only encoder manufacturer to offer a diagnostic tool for all of its encoders with absolute and incremental interfaces: the PWM 21 adjusting and testing package, consisting of the PWM 21 along with the ATS software. This package enables an extensive analysis of the condition of an encoder during machine operation (online diagnostics) and within the context of mounting or repair (offline diagnostics).

Secondary encoders: significantly greater robot accuracy

A seventy- to eighty-percent increase in the absolute position accuracy at their tool center point enables industrial robots to perform more demanding tasks in assembly applications and in the machining of large workpieces. To this end, a secondary encoder for additional motor feedback is mounted to each robot axis on the output side of the respective gear train. At this location, the secondary encoder ascertains the actual position of each robot joint, always taking into account the zero position error and reverse play. Backlash that arises during machining is also measured on every axis of the robot arm.

A typical encoder solution for high-accuracy robots consists of a Heidenhain EBI 1100 or EQI 1100 series inductive rotary encoder for motor feedback, along with a WMKA/WMRA angle encoder from AMO as the secondary encoder. Thanks to its high resilience to contamination, the AMO angle encoder is well suited for being mounted on the outside of the robot. This eliminates the need for planning additional room for encoders within the already limited space of a robotic arm.

Connected Machining: efficient processes through customized networking

The software and hardware solutions of Connected Machining provide ease of data usage, work reduction, time savings, and transparent processes in all relevant areas of the company. Because data can be accessed directly, legwork is reduced, and errors can be all but excluded. Productivity is increased, and processes are streamlined. Uniformly digital, networked job management with Connected Machining thus supports the production-focused strengths of the shop as well as those of the entire company. With the help of the StateMonitor software, applications such as process monitoring and status notification can be shown on the control, on PCs in the network, or on mobile end devices as desired. StateMonitor helps the user keep an overview of the status of his machine and jobs – regardless of the given machine and control type. In an automated production environment, Connected Machining can exchange data with precision over the Heidenhain DNC interface. Transfer units or tool and workpiece handling systems, for example, can thus be provided with the right information at the right time for the creation of an uninterrupted flow of automation. Communication is carried out over the Ethernet interface, supported by common fieldbus systems.