Electric Actuation and Control for the Strapping Machine

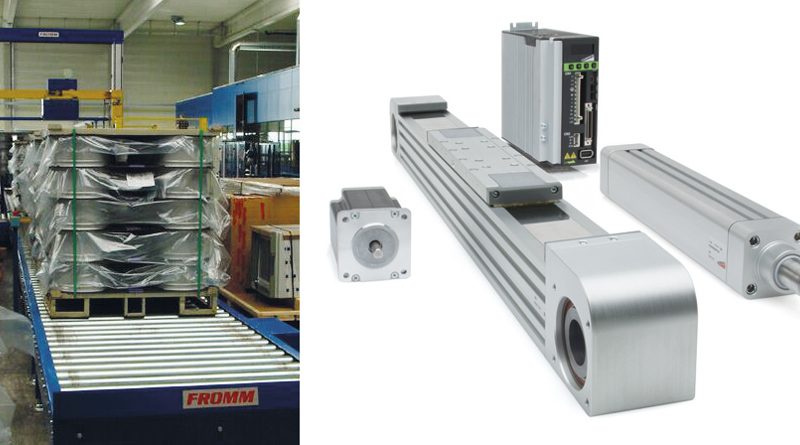

Customization is the strength of the new strapping machine for aluminium wheel rims developed by FROMM Packaging Automation. In order to satisfy the requisites of this application, the company turned to Camozzi, that offered an electric actuation solution, obtaining a better functioning with a considerable reduction both in space and in cycle times.

Ongoing research by machine manufacturers for solutions capable of increasing performances is increasingly often driven by the involvement of the suppliers of components and systems, which are decisive for the optimization of production cycle. Such is the context of the partnership between FROMM Packaging Automation and Camozzi: the former with headquarters in Switzerland and an Italian branch in Caprino Veronese, specializing in the creation of machines for strapping and film wrapping any type of product, the latter with a specialization, dating back over fifty years, in the filed of automation solutions using hydraulic and electrical technology.

Ongoing research by machine manufacturers for solutions capable of increasing performances is increasingly often driven by the involvement of the suppliers of components and systems, which are decisive for the optimization of production cycle. Such is the context of the partnership between FROMM Packaging Automation and Camozzi: the former with headquarters in Switzerland and an Italian branch in Caprino Veronese, specializing in the creation of machines for strapping and film wrapping any type of product, the latter with a specialization, dating back over fifty years, in the filed of automation solutions using hydraulic and electrical technology.

This partnership led to the creation of a new automatic, highly performing strapping machine for aluminium wheel rims.

Characteristics and peculiarities of the new strapping machine

“The new strapping machine has been customized based upon the client’s requests – eng. Fabio Fraccaroli, Managing Director, Fromm Packaging Automation, explained – and intense customization is our strength. The package may vary both in terms of volume and shape. The machine is capable of carrying out two simultaneous strappings, even at different distances.

Thanks to the moving table, strapping may be both transversal and longitudinally crossed. On account of the limited space, the bayonets, in order to fit into the pallet along with the strap, are electrical and evenly distributed, three on one side and three on the other. The overhead pressure, necessary to stabilize the packages, considers the top structure without spoiling them or compromising their stability. On account of the lack of stability and variability of the load placed on the pallet, it is necessary to manage special and variable parts of the package with a different pressure, and at the same time to carry out a double strapping. Having performed this process, the pack of wheel rims is turned by 90° to carry out the other two crossed strappings”.

The solution allowed the critical aspects to be managed

The solution allowed the critical aspects to be managed

For the automation supplier, the challenge was represented by the required cycle times and by the limited space available.

The versatility of the solution proposed by Camozzi allowed these requirements to be satisfied and the application’s peculiarities to be managed in the best of ways.

The problem of the limited space available and of the reduction of cycle times was solved using compact and fast electrical axes, with deceleration ramps to avoid sudden impacts, and halving the stroke of the bayonets so as to reduce, as a consequence, cycle times and inflections. The Brescia-based company provided six 5E series electrical axes.

“This choice – eng. Fraccaroli continued – led to a remarkable reduction both in space and in cycle times, obtained thanks to the increase of sideways motion and to the modular management of acceleration”.

These are just two of the parameters controlled constantly by the Qset software, purposely designed by Camozzi to manage in a simple, fast and extremely flexible way the configuration of all products for electrical actuation, from axes to electromechanical cylinders. Complete control of the movement and positioning of the opposing bayonets also allowed their closure to be optimised, ensuring precision in a very delicate phase of the production process.

A partnership destined to last for a long time

“In order to satisfy our clients’ customisation requirements – eng. Fraccaroli concluded – we involve reliable and high-quality partners. The synergy with Camozzi, capable of providing complete turnkey solutions including mechanical and electrical parts and control software, allowed us to solve all the problems linked to the volume and irregularity of the products. The uniqueness and success of the implemented solution allowed us to obtain, from the same client, another order; besides in consideration of the good functioning of the first two machines we are also finalizing other orders. Thanks to the know-how and the service offered, we decided to involve Camozzi for other applications, concerning both new customizations and improvements on standard machines”.