From Inspection to After-sales Maintenance

During the latest edition of the OMC event, SICK presented a complete package of services and solutions aimed at the Oil & Gas segment: process control, fiscal measurements, anti-collision sensors and emission analysis systems.

by Elena Magistretti

Environmental protection, legal metrology and safety of persons and infrastructures are important factors in the Oil & Gas segment and companies have to tackle these issues with the help of competent partners. The question is not just adopting the best solutions on the market, but it is also necessary to find professionals who can support the client throughout the process of revamping or fine-tuning of the plant.

Even thanks to the presence of a special division which studies every application in detal, SICK can cover the many demands of the Oil & Gas segment. SICK’s team follows several phases. After an initial inspection, the team designs, engineers and assembles complete systems, supervises the installation of the solution developed and, finally, offers a commissioning and after-sales maintenance service.

Especially when monitoring flare gas, norms mandate stringent and regular checks. By means of special Global Service contracts, studied according to each single client’s demands, Sick can guarantee that the system will keep up its initial performances even by means of preventive and correctional maintenance action. This is done thanks to the use of next-generation intelligent systems.

Ultrasound technologies, more “ultra” than ever

During the trade show, the potential of FLOWSIC100 Flare-XT was revealed: this ultrasound flare gas flow metering system is reliable both when the flow of gas is almost imperceptible, and when it rapidly reaches high levels. The titanium measurement probe is designed and shaped to deal with a flow range from 0.03 to 120 m/s without generating any turbulence around the sensor. The system is available in two cross duct and one single probe versions for all hose cases when an installation on both sides of the flare collector in impossible or not recommended.

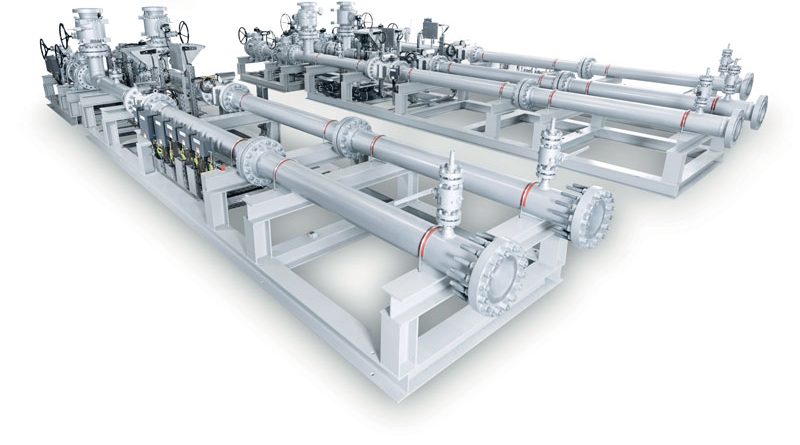

The standard version is equipped with two emission/reception units, a measurement probe and an “MCUP” control unit. Being compatible with all communication architectures, the instrument may be used in any process. The FLOWgateTM software shows on real time the data collected by the sensor and makes them available for diagnostic purposes, thereby ensuring a constant quality of measurement performances or notifying the Service that action is required. Besides, for fiscal measurements, SICK will showcase FLOWSKID600, a complete system for gas flow measurement made up of a fiscal ultrasound FLOWSIC600 XT measure combined with the Flow-X flowcomputer by SICK, everything being managed by a next-generation surveillance system,

A LiDAR for the security of persons on board the ship

Protecting areas and accesses, but even persons: LiDAR 3D MRS6000 was designed for these purposes. The probe replaces surveillance cameras, which cannot generate alarms systems if dangerous situations arise. MRS6000, on the contrary, informs operators as soon as an object enters its 120° scan area. The IP67 protection level makes it suitable for outdoor use, where it is more likely that false alarms may be generated. To prevent this risk, the LiDAR may be set to identify objects larger than a predefined volume.

Considering for instance, its use on merchant ships, it is possible to block signals deriving from water spray caused by waves of from birds, causing the device to be sensitive only to human figures. l