Global Partnership for the Automotive Market

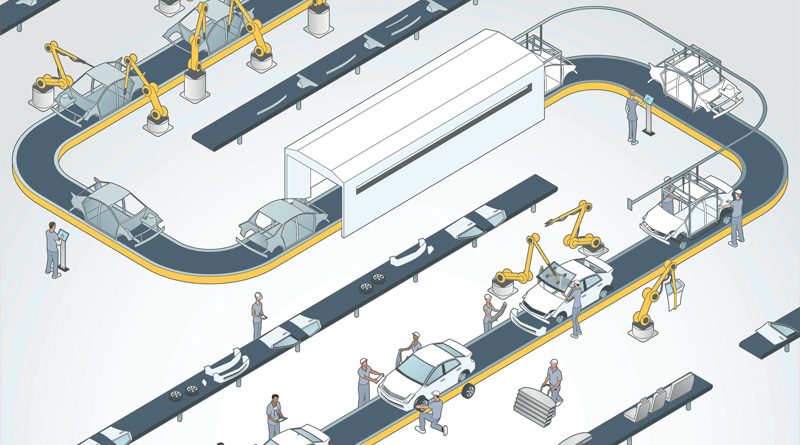

Parker provides the automotive market with a number of solutions: actuators for welding robots, piping systems for compressed gases, filtration systems for air filtering and conditioning and many more…

by Alma Castiglioni

Automotive manufacturers challenges are manifold: globalization to address growing markets; TAKT time efficiencies (the rate at which a finished product needs to be completed in order to meet customer demand); storeroom proliferation; overall productivity… Parker meets these challenges by offering a range of dedicated solutions: localized product and service with more than 300 global factories and 13,000 distribution network locations; a machine schematic review process ensuring the most efficient systems are provided to customers; Program management services in order to commonize the product used on a program and makes recommendations for ongoing management of spare parts inventory; a capillary sales and distribution network for system diagnostics, product functionality, and product lead time to ensure manufacturing productivity.

Specializing in hydraulic, pneumatic, electromechanical, fluid connection and filtration, the company can act as a single-source partner for all automotive market requirements.

A range of key products for the automotive sector

Here are some of the key products that Parker supplies to the automotive industry. Addressed to welding robots is the Water Retract Actuator (WRC). The unit stops water expulsion. The integrated design allows for dry weld tip changes and keeps water off equipment, and out of the production cell. Paired with the Water Saver, the Water Retract Actuator (WRA) stops weld water expulsion from the robot during tip changes, keeps water off equipment and electronics within the cell, reduces water consumption costs and the need for expensive chemical additives.

The Transair brand is linked to piping. Transair piping systems offer a number of benefits such as corrosion resistance; immediate pressurization; production of clean air and leak-free guarantee.

Air filtering and conditioning solutions and much more…

In the compressor room, Parker offers many products to filter (clean) and condition (dry) the air, before it is distributed throughout the plant. Parker can even carry the controlled air through an integrated supply system.

The company can assist with most applications across a full range of sizes. But there’s more. We only mention a few more products used in car manufacturing processes. Parker portable filter carts are the ideal way to pre-filter and transfer fluids into reservoirs or to clean up existing systems. Portable filter carts are an economical way to protect the system from the harm that can be caused by contamination.

LaserCM Portable Particle Counter for Fluid Condition Monitoring are another example of and customer driven development. Now a new version is available, featuring opto-mechanical technology and continuous wave single point source laser (SPSL). Eventually, Desiccant dryers are a simple and reliable method of protecting sensitive pneumatic equipment from exposure to damaging moisture.