High Efficiency Class for the New HVAC Motors

Designed for applications in the heating, ventilation and air conditioning field, WEG’s new energy-efficient permanent magnet motors (achieving the IE5 efficiency class) are specifically conceived for radial and axial HVAC applications. At SPS IPC Drives 2018 in Nuremberg, the company also showcased the range of geared motors, integrated system inverters, as well as the latest condition monitoring solutions.

by Cesare Pizzorno

At SPS IPC Drives 2018 in Nuremberg, WEG introduced the brand new motors capable to achieve an industry-leading efficiency level (IE5). The electronic controlled IEC motors (WECM) are designed for applications in the heating, ventilation and air conditioning (HVAC) field. At the German exhibition, WEG also showcased the new Motor Scan condition monitoring technology, enabling real-time monitoring of WEG electric motors via a smart device App, thus allowing for predictive/preventive maintenance. Also on display were the WG20 range of geared motors for rated torque levels up to 18,000 Nm and the MVW3000 series system inverters for low- and medium-voltage applications.

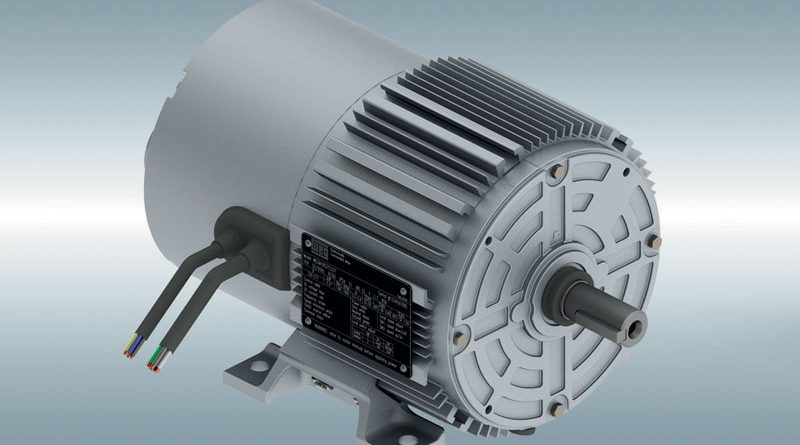

Energy-efficient HVAC motors for the IEC market

The electronic controlled WECM motors have been specially designed for radial and axial HVAC applications within the IEC market. These energy-efficient permanent magnet motors cover a power range of 0.12 kW to 1.1 kW and rated speeds of 1,500, 1,800 and 3,000 rpm. Thanks to the integrated electronic speed control system, the drive package achieves the IE5 energy efficiency class and comply with all relevant IEC and HVAC standards.

Due to their high energy efficiency and very good practicality, the motors with low noise emission and reduced vibration levels are indeed a cost-efficient solution for fans or aerators manufacturers.

From powerful geared motors up to integrated system invertersOffering rated torque levels of up to 18000 Nm, WEG’s WG20 range of geared motors deliver efficient power transmission and in combination with WEG flanged motors up to 75 kW and with efficiency classes up to IE4, this solution is ideal for demanding applications within steel, energy and mining. In addition, they help significantly with machine/plant availability through the high level of operational safety and low maintenance. The MVW3000 integrated system inverters, made in Portugal, cover voltage levels from 2.3 kV to 8 kV and power ratings from 280 kW to 2,400 kW. The big advantage here is that the inverters are available as complete system fully integrated in cabinets, with circuit breakers, fuses, multi-level input transformer and frequency converter.