High Precision and Dynamics in Machine Tool Couplings

Couplings are important connecting elements, and connected systems are the building blocks of intelligent production. When chosen wisely, couplings improve the performance of production processes and enable the desired speed, safety and precision te be achieved.

R+W is in possession of a strong know-how in the field of couplings for machine tools. Machine tools are demanding applications for drive components: they have to work quickly, flexibly and precisely and of course effectively. Factors such as damping, torsional rigidity, balance, and inertia are taken into account and perfectly coordinated. R+W has the necessary industry experience to offer the right coupling solutions for every machine tool.

R+W is in possession of a strong know-how in the field of couplings for machine tools. Machine tools are demanding applications for drive components: they have to work quickly, flexibly and precisely and of course effectively. Factors such as damping, torsional rigidity, balance, and inertia are taken into account and perfectly coordinated. R+W has the necessary industry experience to offer the right coupling solutions for every machine tool.

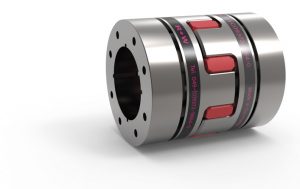

The coupling has a huge influence on drive train behaviour and ultimately on the system as a whole. R+W offers various series of zero backlash, precision engineered couplings, which aim to reconcile highly dynamic loading with exact repeatability and torque transmission. To accomplish this task, R+W’s portfolio of zero backlash models includes vibration damping elastomer couplings, torsionally rigid metal bellows couplings, and disc pack couplings, as well as torque limiting safety couplings.

Precision, zero backlash joints to master highly dynamic loads

Zero backlash, precision elastomer couplings from R+W damp vibration while simultaneously providing good torsional rigidity for a high degree of positioning accuracy. They are sized for a torque capacity range from 0.5 to 25,000 Nm, depending on the design, and can compensate for axial, lateral and angular shaft misalignment. If selected correctly, the elastomer insert, which is the compensating element of the elastomer coupling, optimizes the torsional vibration of the entire drive train. R+W offers inserts with various Shore hardness values and other characteristics to meet different challenges, enabling it to satisfy requirements for damping, torsional rigidity, electrical conductivity and thermal stability. In most cases a good compromise can be found between damping and stiffness.

R+W elastomer couplings are available with easy-to-install clamping hubs, split hub designs, or with expanding shafts, to name a few. The SP6 elastomer coupling has been developed for high speed applications such as spindle drives. Its elastomer insert damps vibration, but still introduces zero backlash into the system as a result of its precision preload between the drive jaws. Two precision machined hubs with conical clamping ring systems and concave driving jaws provide for smooth running through a high level of concentricity and balance.

Position accuracy with torsionally rigid metal bellows couplings

R+W zero backlash, torsionally rigid metal bellows couplings are ideal for meeting the specific challenges of highly dynamic servo axes in machine tools, gear cutting machines and other automation systems. These high precision drive elements are used wherever positioning accuracy is the top priority. They provide cost effectiveness and a high level of operational dependability through their durability and freedom from maintenance. The metal bellows coupling models transmit torques from 0.05 to 100,000 Nm in a variety of hub designs. What’s more, they compensate for axial, angular or lateral shaft misalignment. Just like elastomer couplings, metal bellows couplings can be ordered with different hub combinations and adapted for different types of shaft.

The ideal coupling for high-speed applications

New to the R+W range and ideal for high speed applications is the SP3 metal bellows coupling. This coupling, which features external conical clamping ring hubs, offers smooth running even at extremely high speeds. The rotational symmetry also guarantees excellent balancing quality. Alongside the applications already mentioned, metal bellows couplings are also used in test stands, paper converting machinery, printing and labelling equipment and packaging machinery. Miniature versions extend the potential applications further into measurement and control systems, smaller servo drives and rotary encoders.

High durability and performance with disc pack couplings

Disc pack couplings offer variety of potential application areas: they are the ideal solution whenever high durability and performance are the order of the day. With its disc pack couplings R+W offers a highly stiff range for torques from 350 to 24,000 Nm. Disc pack couplings are available in several designs.

The LP3 (double flex) and LP4 (single flex) zero backlash models with conical clamping ring hubs are suitable, among other things, for applications with high reversing torques.

Alongside various standard designs, this torsionally rigid series can now also be purchased with an integral coolant delivery system through an intermediate drive shaft tube. This gives manufacturers of machine tools, particularly those with a long spindle design, some real advantages. These specially designed double-flex spindle couplings can guide the coolant directly

to the tool across long distances, using an integral pipe with sealed adapter interfaces on both ends. Symmetrical conical clamping ring hubs and dynamic balancing also ensure excellent smoothness and minimal vibration. Further, any shaft misalignment is compensated for by the torsionally rigid flexible disc packs.

This robust and powerful series thus offers users a simplified spindle design, shorter assembly times, faster machining speeds

and longer service lives.

Safety couplings protect the critical components of the machine tool

The zero backlash precision safety couplings available from R+W in the SK, ES and SL (ultralight) series, with torques ranging from 0.1 to 2800 Nm, provide even more advantages.

The preset disengagement torque enables these safety couplings to protect other machine components, such as gears, shafts, ball screws, etc., from a torque overload and subsequent damage in the event of a crash. This allows users to reduce downtime in the event of malfunction.

Higher torque versions from the ST series, with capacities up to 250,000 Nm and beyond, are also available from R+W’s Industrial Drive Coupling product segment for heavier duty applications.