Interested in Whatever is New

Specialising in the field of connectors and coils for solenoid valves, ATAM has been following a path focused on innovation for half a century. The company has made product customisation one of its strengths, also targeting niche markets such as the ATEX and IECEx worlds and products with VDE and UL certification. Andrea Ciceri, COO of the company, talked to us about the latest investments, innovative applications and much more…

The path followed by ATAM in its first 50 years is marked by innovation. Half a century of history during which the company has evolved thanks to continuous investment in the automation and interconnection of its structures, in R&D and in staff training. We talked about innovation in all its aspects: product, process, management and auditing innovation. InMotion interviewed Andrea Ciceri, Chief Operating Officer, to talk about this and much more.

InMotion: ATAM places innovation at the heart of its business. Can you tell us about recent investments in this direction?

Andrea Ciceri: ATAM’s propensity to invest is definitely very strong. Let us start with the development of new products and, specifically, of three major innovations. The first is an innovative contact for our connectors. For years, we have been using a highly evolved contact based on a system for connecting screwed cables; now, starting with this contact, we have added an elastic connection device. We have therefore invested in equipment to sample this contact which could lead to a small revolution in the world of electrical connectors for solenoid valves, drastically reducing wiring time and costs. Other projects have involved the miniaturisation of solenoid valves, which are applied to the world of hydraulics, the main outlet market for our products. Years ago we were the forerunners of this type of product, which involves the integration of the coil and the valve, but recently, in co-design with the customer, we were able to create an even smaller one, aimed at earth-moving machinery and tractors. This project has set an example and has now become a standard in the world of low-cost hydraulics. Miniaturisation, in the fields of hydraulics, pneumatics and automation, is one of the fields where we see the greatest development potential. I am thinking, for example, of the pneumatic braking of large vehicles (rail transport, for instance).

Another new project in which we have invested is the development of a series of coils with an external magnetic circuit: these coils are used, again in the field of hydraulics, on forklift trucks, a challenging application in terms of the performance/energy consumption ratio. On a forklift truck, it is the batteries themselves which take care of all the movements, so vehicle autonomy is of the utmost importance. In this application, our ultra-high-performance coils with low current consumption were a big step forward; they were offered to the two biggest players in the industry and were very successful.

Another field in which we have always invested is materials research. A few years ago we developed a new material which allows us to homologate our product according to thermal insulation class H, which corresponds to a continuous temperature of 180° C; today we are using it in mass production with the major players in the hydraulics sector where the required performances must reach very high thermal classes. This innovative and competitive material is able to offer performances higher than the maximum achievable until a few years ago, it had never been used on coils.

Our commitment to researching new materials has never stopped. We use at least ten different families of materials in our company, divided into thermoplastics and thermosetting plastics, divided into 25 subtypes, for the overmoulding of the coil, an apparently simple operation, but with a lot of know-how and production technology behind it. We are also investing resources in industrial automation with a programme to renew our machine park, from injection moulding machines for overmoulding plastics onto our products, to machines for final testing, which in our case is particularly severe.

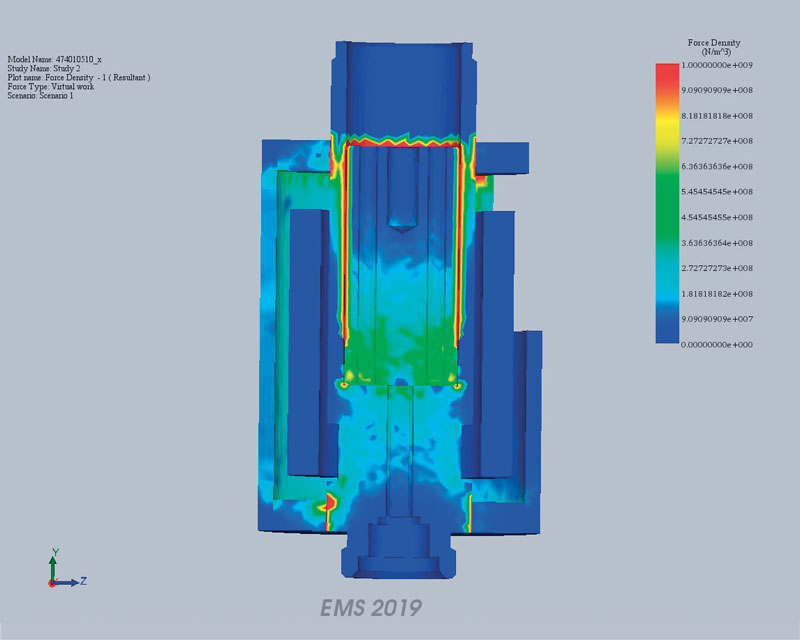

These are automated machines which require minimal operator intervention. Besides, specific equipment is being developed to check the quality of the incoming electronic components, which will analyse the real performance in operation, compared to the specifications declared by the manufacturers. A type of verification which is difficult to carry out, if not by the manufacturers themselves, which makes ATAM the only solenoid manufacturer able to guarantee full conformity of the electronics on board the coil. Other innovations concern product management. We have created a customised management system incorporating the PLM function, thanks to which we are able to track every single stage of the product’s life, from the receipt of the request for quotation to its dispatch, through the manufacture of the individual components, assembly, overmoulding and testing. This provides us with the ‘history’ of each product, including laboratory reports and the decisions made in each individual choice. The next step will be to share the relevant points of this history with our customers, using traceability methods which are now internally established, so as to allow them to have all the information on each individual product or production batch. Implemented since January 2020, our PLM is being continuously refined and adapted to our needs and those of the customer. I would like to conclude with design: we have recently adopted a new CAE FEM module: a multiphysics analysis system which analyses the magnetic field generated by our product, the incidence of magnetic fluxes within the magnetic circuits, the force of the actuator mounted on the coil and the temperature developed by the product and its dissipation; we thus have a complete analysis of everything inherent to its application.

IM: Product customisation characterises ATAM’s activity. Design is carried out in co-design with customers. How important is this synergetic work for your business?

AC: The customisation capacity, for electric coils alone, represents 70% of what we produce. Customisation is possible thanks to the strong know-how of the R&D department, capable of offering specialised consulting which goes beyond product development, involving the entire solenoid-valve assembly or electrical connection. Our philosophy is based on listening to the customer; we are therefore in constant contact with the customer’s technical department; we work in synergy from the conception of the product through to its marketing, also assisting the customer in obtaining specific certifications. Our strategy is to direct customers towards technologies which are accessible to us, offering them as quickly as possible an original product customised in terms of performance, dimensions, environmental conditions, packaging, delivery… taking into account even the methodologies and manufacturing processes in place in their company. All with the utmost transparency.

IM: Your capabilities in terms of product customisation and constant research work lead you to develop innovative products not yet available on the market.

AC: This is the case. Our continuous commitment to research often leads us to act as market pioneers in the field of pneumatic constructions and automation. Often customers turn to us because they need something really innovative, not available on the market. Allow me to provide a few examples, starting with research into insulation materials for overmoulding our products, depending on the environment in which they operate.

We were the first in the world of pneumatics to integrate the operator inside the coil, a configuration which saves costs. We were the first to include electronics within the overmoulding. We pioneered battery cell climate control for hybrid and electric vehicles. We pioneered miniaturisation in hydraulics, pneumatics and automation, one of the areas where we see the greatest potential for development. We have entered the field of medical applications, combining all of our know-how… We are proud to be pioneers in these particular applications.

IM: In its activities, ATAM pays particular attention to certifications. ATEX applications are an area in which you are particularly specialised.

AC: We follow several international standards, and apply the best of these standards to our products in order to maintain a high degree of production flexibility. The Atex regulations, in particular, affect us closely. Our Technical Director, who comes from that world, has brought with him all his experience in a field where regulations are constantly evolving. Moreover, our Atex representative has a long-standing collaboration with one of the main Italian approval institutes in this field. We deal with Atex applications with two product ranges, one aimed at the world of pneumatic automation and the other at the world of hydraulics.

IM: To carry out an activity of this kind, it is essential to have strong know-how and specific skills, and therefore dedicated professionals. When is it important to invest in training resources?

AC: In our company, the training process is continuous. We constantly aim to transform real skills into the ideal skills to fill positions within the company, through specific courses. To provide another example of on-the-job training… every day at 8.30 a.m. in our Daily Scrum Meeting we exchange information with all functions in the organisation so that everyone can be aware of what is going to be done during the day. It is a time when know-how is spread across all functions, problems and information are shared, so that even those who are not directly involved are made aware. With a view to exchange and continuous improvement, once a month, in a more structured and enlarged meeting called “improvement committee”, all the main indicators of the company (production, purchases, sales, performance and so on) are analysed, so as to inform everyone about the general trend and the main points of attention. This kind of management is essential for a company which produces and manages 5000 codes, with production volumes of 7/8 million coils per year and the same number of connectors.