It’s time to make choices for our future

Machine manufacturers cannot neglect the ‘sustainability’ aspect of the products they put on the market. In the field of pneumatic automation, there are three thematic areas of interest: compressor room, distribution network, uses. If the third area is neglected, there is a risk of “efficiently feeding inefficiencies”. Let us see how it is possible, with the help of a global player in the field of pneumatic automation, to raise the level of efficiency of a machine.

Machine builders, who until very recently developed their designs taking into account the three parameters of productivity/quality/cost, now cannot fail to include a series of options which increase the “sustainability” of their machines, so as to offer even more appealing solutions to their customers.

Applying this concept to the field of automation, with particular reference to pneumatic automation, and taking an industrial reality as

a point of reference, it is possible to identify three main areas: compressor room, distribution network, uses (applications, machinery, utilities, etc.).

In recent years there has been a strong drive to replace traditional compressors with variable speed models, as well as proposals for recovering the heat produced (it is worth pointing out that the best part of the energy absorbed by compressors, about 75%, is converted into heat). This is undoubtedly a positive approach; however, by forgetting the third field, that of compressed air usage, there is a risk of “efficiently feeding inefficiencies”. Focusing on the use of compressed air, a number of simple but effective solutions for increasing the efficiency of machinery are considered here: these suggestions are applicable throughout the manufacturing sector.

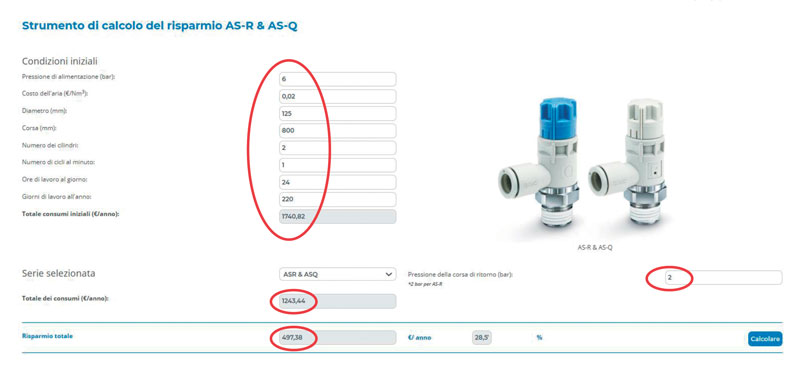

Figure 2: Saving calculator AS-R & AS-Q.

Figure 3: PF3A flow switches from SMC.

Use only what is strictly necessary, where necessary

First of all, it is important to act in such a way as to use only the pressure level required, that is, to use only what is really necessary. The old style of design generally involved only one pressure level, or even a direct connection to the mains pressure. A pneumatic machine consumes according to the supply pressure; subdividing its macro-functions by giving each one the correct operating range leads to significant energy savings, and is a relatively simple operation to carry out. Dedicated pressure valves (SMC’s AR series for example) can be a winning solution. Aiming for an average machine pressure of around 0.4 MPa is not an unrealistic goal; systems such as VBA boosters can then selectively raise the pressure. Another simple but very effective solution is represented by SMC’s ASR-ASQ series: it can be fitted anywhere in a machine where a pneumatic actuator only delivers force in one of the two strokes. Taking the example of a forklift which lifts a weight and then returns to the idle position, the result will be that instead of using, say, 0.6 MPa for both strokes, the speed controller will perform the idle stroke with reduced pressure in order to save energy (Figure 1). Figure 2 shows an example: assuming a supply pressure of 6 bar, an average cost of compressed air of 2 eurocents/m3, 2 large cylinders with very slow cycles, a machine working 24 hours/day for 220 working days/year. The two cylinders have a consumption, in economic terms, of 1,740 euro. By lowering the return stroke to 2 bar, consumption is reduced to 1,240 euro, a saving of almost 500 euro, which is a considerable amount. It is easy to imagine how much could be saved worldwide by adopting this type of solution. In order to recover some of the compressed energy circulating at certain points in the system, solutions such as energy recovery cylinders or boosters can be a viable alternative to conventional systems, reducing compressed air consumption by up to 46%.

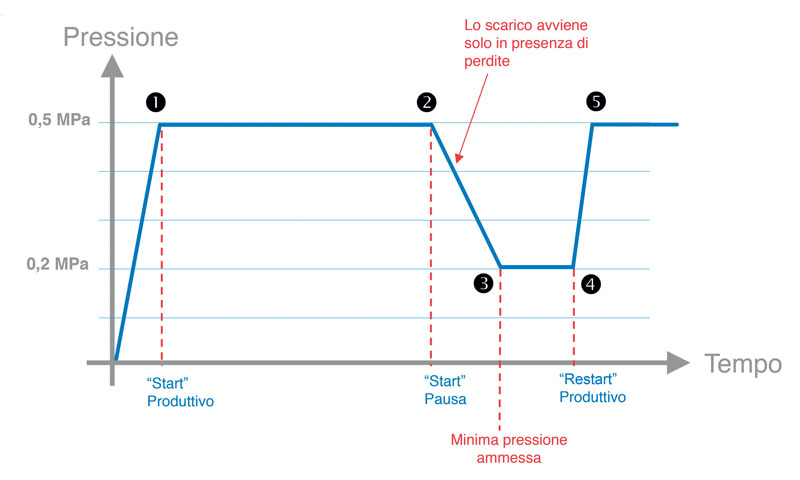

Figure 4: From a monitoring and saving standpoint, another important technical element is the stand-by system (VEX valve).

Figure 6: Vacuum units ZK2 can automatically modulate vacuum while reducing consumptions.

The contribution of consumption monitoring systems

Monitoring systems play a key role in this scenario. Instruments such as the PF3A flow switches (Figure 3) help to keep consumption under control, but not only. They also allow you to assess energy drifts, foreseeing possible plant downtimes in advance. This not only improves energy efficiency, but also the efficiency of the machinery itself, increasing productivity from a predictive maintenance standpoint. Connecting these tools to the supervision systems brings us into the field of Internet of Things (IoT), also allowing remote management. Once again, from a monitoring and saving standpoint, another important technical element is the stand-by system (VEX valve): a valve which, during periods of production stoppage, if the plant is not to be unloaded, allows the machine to lose pressure, due to physiological losses, up to a set value, and then keeps this value stable. In this way the prompt restart of the machine will be guaranteed, but the incidence of losses will be drastically reduced. (Figure 4) Assuming a machine operating at 6 bar, with widespread losses comparable to a hole of only 2 mm, a cost of compressed air of 2 cents/m3, a machine “full of air” 24 hours a day, but working only on 2 shifts. The 2 mm hole causes an annual loss of €2,200. In this case 33%, that is, the 8 hours at night, is the suspension time. If, during the night the valve is assigned the task of maintaining 2 bar as the maximum value, the result will be a saving of 500 euros/year. This means ROI in just one year (Figure 5). Leakage is a concern for every production site. In addition to providing support on this issue, SMC offers a range of products (ALDS leak detection systems) which can interface with the PLC to automatically search for the point in the plant where the leak occurs, providing an accurate and timely assessment of the extent of the leak.

Correctly sizing components to optimize consumptions

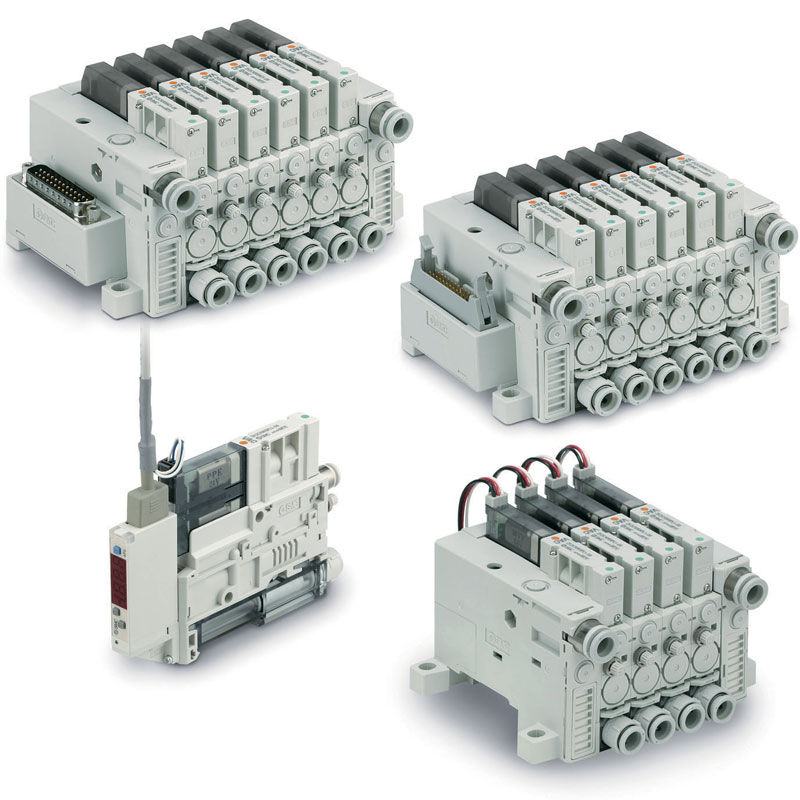

The sizing of components is a separate issue. In pneumatics, the standardization criterion is often used rather than correct calculation. As a result, we are often faced with applications which, although functional, are heavy and disproportionate. Correctly calculating valves, hoses and actuators enables the optimization of consumption; reducing the CO2 impact during the production of these components; in the presence of robots, it allows to increase the dynamic performance of the system; finally, it makes it possible to save further CO2 in the product disposal process. To this end, SMC has developed free software and is launching on the market innovative ranges of actuators and valves which, while providing the same performance, have more compact dimensions.

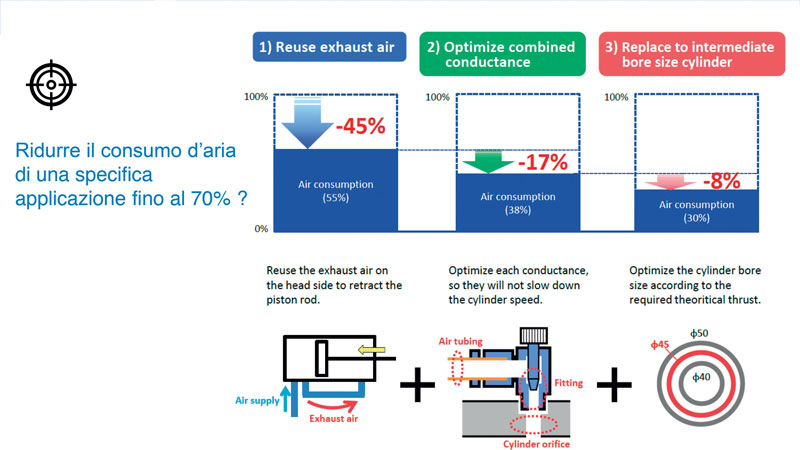

Last but not least is the issue of intentional blow-outs; that is, those losses generated specifically for a purpose: cleaning, drying, vacuum generation, and so on. These techniques are energy-intensive, but often effective and indispensable. Today, innovative solutions are available such as energy efficient or flow multiplication nozzles (KNH, ZH-X185), Vacuum units capable of automatically modulating the vacuum and reducing consumption (ZK2, figure 6), or valves which make blowers intermittent, thus reducing consumption (AXTS-X2). These are all smart solutions designed not for the factories of tomorrow, but for the factories of today. Let us see how compressed air consumption could be reduced by 70% in a hypothetical application, with the same system performance. By using, where possible, an air recovery cylinder, the potential reduction in consumption is already 45%; by optimizing the size of the components, a further 17% is achieved; finally, by adopting the optimum cylinder size, another 8% is achieved… reaching the set target. (Figure 7)

Listening to alarm signals and reacting immediately will be essential

What is important, however, is to “interiorize awareness” and learn to listen to alarm signals. To increase efficiency, it is necessary to take one step at a time, seizing every opportunity for technical rationalization, even those which are apparently insignificant. Installing a speed controller may seem like a drop in the ocean, but considering the hundreds of thousands or even millions of actuators operating simultaneously worldwide, it is possible to estimate the savings in terms of emissions. Driven by environmental disasters, it seems that social consciousness is awakening. Being innovative and offering sustainable machinery will not only be a challenge, but also one of the great opportunities of tomorrow. Remaining close to tradition will involve the risk of facing the challenge when it arises; moving now expresses the will to seize this opportunity. It is thanks to their talent and spirit of innovation that Italian automation manufacturers will be able to handle this transition successfully.

About the author: Danilo Giordana is Energy Efficiency Project Manager at SMC Italia.