Keeping a Constant Eye on Conditions and Torque

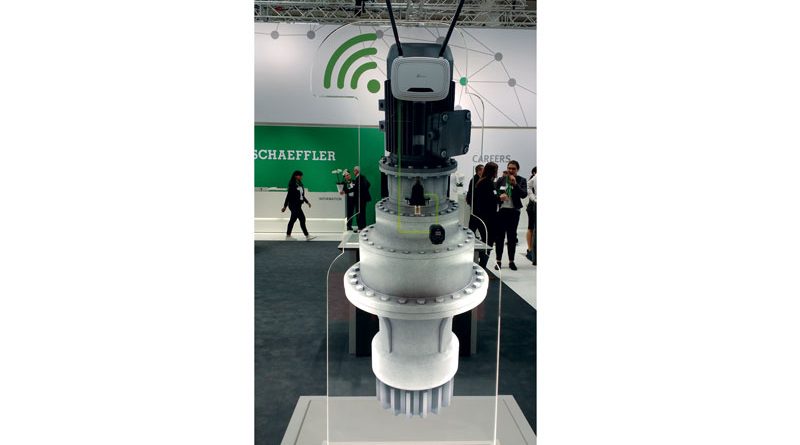

Schaeffler combines condition and torque monitoring in a single system. At Hannover Messe the company presented a pilot project, developed in partnership with Bonfiglioli, for the wind power industry.

by Silvia Crespi

The long-term development partnership of Schaeffler and Bonfiglioli, a pioneer in the field of power transmissions for wind turbines (yaw and pitch drives), lead to the creation of a compact Industry 4.0 solution package. Schaeffler has combined two of its proven measuring systems, the SmartCheck and the TorqueSense to create a new condition and torque monitoring system. While the vibration diagnosis system of the Schaeffler SmartCheck detects incipient damage at a very early stage, peak loads as well as their frequency can also be detected and limited using the precise torque signal. Using algorithms that are based on their application expertise, Bonfiglioli converts such data into information throughout the entire lifetime of a wind turbine. Thus, online reporting on relevant performance indicators is provided, e. g. the general “health” status of the geared drives, possible critical conditions, and abnormal behavior of the yaw systems. Customers benefit from increased drive availability and longer maintenance intervals.

At the Schaeffler Group stand at Hannover Messe, we met Roberto Rosso, President Industrial at Schaeffler Italia and Francesco Capittini, Technology Center Manager at Schaeffler Italia, who explained us how the project was born: “In wind turbines, the adjustment of the position of the nacelle is fundamental: it must, in fact, be oriented in such a way as to exploit the direction of the wind as profitably as possible. This task is entrusted to a series of gearboxes, named yaw drives the number of which varies according to the size of the turbine. The pinions of these gearboxes engage on the toothing of a slewing ring. First of all, it is important to control the behavior of these gearboxes in order to be sure that each of them operates in a balanced way compared to the others. To this end, Schaeffler and Bonfiglioli developed a prototype, which we present at the fair, with both the vibration and the torque monitoring of the individual gearbox.”

A clever monitoring combination

The Schaeffler SmartCheck device performs frequency-selective condition monitoring of bearings, gearboxes, electric motors, pumps, fans, and machines based on solid-borne vibrations. Conspicuous frequencies can be automatically attributed to the damaged component using only one Schaeffler SmartCheck. A temperature sensor is also integrated into the device. The torque signal and speed signal of the Schaeffler TorqueSense are sent, preprocessed and supplied to the machine control system and/or maintenance department with the vibration signals that are also analyzed via the SmartCheck. The addition of operating data on torque and speed to the SmartCheck condition monitoring system opens up several new scenarios. In the simplest case, the system allows the monitoring of torque peaks and their frequency and thus an evaluation of the utilization level and the derivation of load-based maintenance measures. The signals can also be integrated into the operating strategy for drives and initiate torque limitation or shutdown functions.

A pilot project for the wind power industry

In the application developed in for Bonfiglioli’s geared motors of yaw drives for wind turbines, the operational data elaborated using the Schaeffler SmartCheck are compared with predefined limit values and the results are transmitted wirelessly to Bonfiglioli via a gateway. The monitoring system for Bonfiglioli geared motors operates independently and is not connected with the turbine’s control system, making it very easy to retrofit when the geared motors are replaced.

With this system, Bonfiglioli aims at monitoring overloading of the yaw drives, increase the lead times for maintenance, and make it possible to define load-based instead of time-dependent maintenance procedures. The TorqueSense module is positioned between the motor and gearbox to integrate it into the flow of force of the geared motor. The measurement system is also fully functional in lubricating oil and offers significant advantages for integration into the drive train such as: high measurement accuracy (approximately 1% of the measuring range) at an attractive price, non-contact measurement principle, no change in the load carrying capacity and torsional rigidity due to the sensor shaft, temperature has a minimal influence on the operating life and measurement accuracy, and integrated speed measurement.

“The value of the application – adds Capittini – lies also in the harvesting of the data, which can reconstruct the status of the machine

at a given time. A digital model of the gearbox is created and through a numerical simulation the residual life of the components and the maintenance intervals to be programmed are measured, with a true view of 4.0.

The solution is currently undergoing field tests in on-shore wind farms, but it will be interesting also for the off-shore market where maintenance needs are even more important”.

However, wind turbines are not the only application. The new system is particularly suitable for adjustment and rotary drives in the wind power and shipbuilding industry, in large cranes, construction and mining machinery with turrets, and for winches.

The torque signal can be used for both monitoring and smooth and precise torque control and regulation of the pull cable.

“With Bonfiglioli – Rosso and Capittini conclude – we developed and presented at Hannover Messe as a première – also a multi-channel condition monitoring system, the Schaeffler ProLink, the SmartCheck, which will be launched on the market in the coming months. The system shares software and self-learning capabilities with SmartCheck, but it is modular. It allows up to 4 units to be connected with four measurement points each and communicates with the most popular communication protocols.

Like the SmartCheck, it is remotely accessible via an IP addressfrom anywhere in the world”.

Torque sensor technology can be easily integrated

Schaeffler TorqueSense comprises a magnetically conditioned section of shaft and a sensor housing. The housing does not have to completely surround the shaft.

Designs that are mounted on one side only or U-shaped designs are possible depending on the required accuracy and interference immunity. Because a non-contact measurement principle is used, the torque can also be measured from outside by means of a non-magnetic housing. The sensor module can then be mounted from the outside. With Schaeffler TorqueSense, customer and application-specific shaft diameters of up to approximately 100 mm are possible; sensor units in different standard diameters already exist. The measuring range is from 100 Nm to 20 kNm.

The sensors have high linearity and extremely small hysteresis due to the measurement principle used.