Lifetime Lubrication Extends Components Life

With its rich and varied product portfolio, Castrol provides customized lubrication solutions for particularly critical applications: from new mobility concepts such as electric scooters, electric bikes and similar to the Mars Rover. In such applications lifetime lubricants must satisfy a very special set of requirements, extremely varying temperatures, high rotational speeds and contact pressures, so that components may run like clockwork.

Mobility is constantly evolving, and this is true for both traditional technologies and the new mobility concepts. Electric vehicles, namely, poses new challenges on components and lubrication plays a big role in this variegated scenario. As opposed to standard lubricants, Castrol’s product range, consisting of a variety of high-performance lubricants, greases and lubricating pastes offer customized solutions for particularly critical applications. This is also true for lifetime lubrications.

Opening picture: Castrol’s product range, consisting of a variety of high-performance lubricants, greases and lubricating pastes, provides customized solutions for particularly critical applications.

Opening picture: Castrol’s product range, consisting of a variety of high-performance lubricants, greases and lubricating pastes, provides customized solutions for particularly critical applications.

All the requirements lifetime lubricants must satisfy

We refer to lifetime lubrication when a lubricant is used in components that are designed for continuous use in the vehicle and which are generally not re-lubricated over their entire lifespan. In their application, lifetime lubricants must satisfy a very special set of requirements. The lubricants used must work under highly varying temperatures, high rotational speeds and contact pressure, and ensure efficient lubrication in encapsulated components throughout their entire lifetime, for example. This requires a maximum level of reliability, functionality, durability and optimised material compatibility. Castrol lubricants have already proven such qualities in extreme situations, such as when in use on the Mars rover or the International Space Station (ISS). All of these characteristics of lubricant design form the basis for the current research and development portfolio of Castrol/BP and aim to fulfill both the current and future needs of the developing market for electric vehicles. The company’s current R&D investments increasingly focus on the development of new polyurea greases for electric motor applications, where rapid surface contact with high speed and a broad operating temperature range present unique challenges in the field of noise protection. In addition, understanding the effect electrification has on drive shaft applications supports the development of the next generation of uniform running shaft grease in order to protect increasingly miniaturized components under increasing torque while ensuring the long durability our customers demand along with the critical surface protection. In the following, you can discover some examples of application possibilities in which the versatility, resistance and innovation of Castrol’s high-performance lubricants have proven their worth and have satisfied the requirements defined by their customers’ specific application profiles.

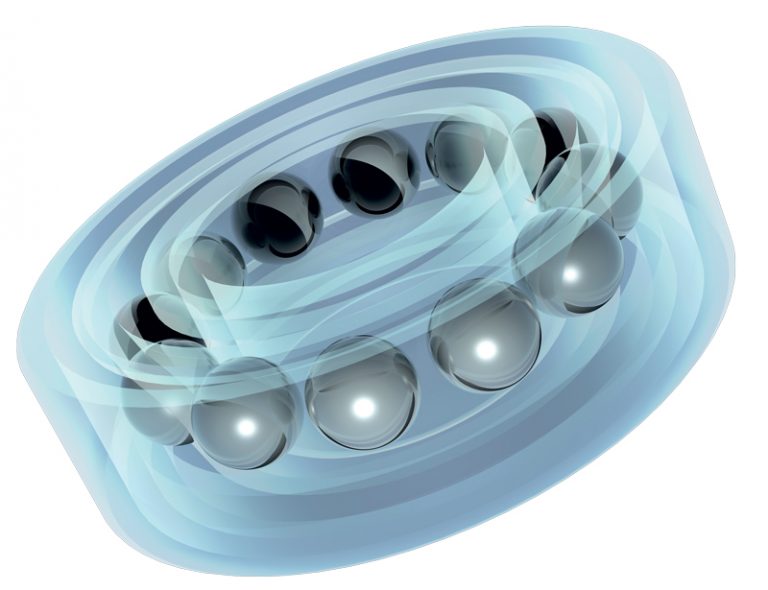

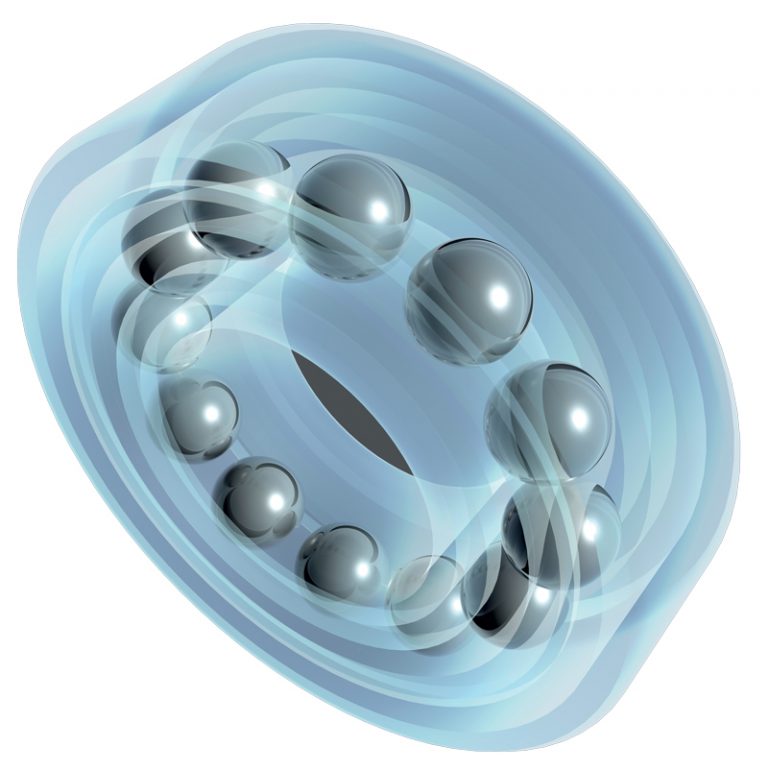

As the key component of every wheel, rolling bearings are among the most widespread and most important machine components.

As the key component of every wheel, rolling bearings are among the most widespread and most important machine components.

Maximum performance on the cycle path

Electric bikes and pedelecs are becoming increasingly popular and play an important role in future mobility, in both urban and rural areas.

Modern electric bike drives have now been on the market for more than ten years. During this time, the demands on the transmitted torque and idle times have increased significantly. The latest generation of drives must transfer up to 90 Nm of drive torque in the highest performance versions. These torques are in the range of currently available small cars. To compare: the current VW Polo VI 1.0 L has a torque of 93 Nm.

Numerous lubricants with different technologies could not meet the requirements of the new drive systems. Wear and tear was too high and the lifespan too short. Castrol’s Tribol GR series with PD technology, can provide the desired lubrication performance and double the lifespan of the transmission.

The PD technology already forms an additive film at low load and low temperatures to protect the surfaces. Under high loads, the components of an additive combination are activated, which optimises the surfaces and their tribological properties by means of plastic deformation and micro-smoothing of the contact surfaces. The supporting part of the surfaces can be increased and the hydrodynamic lubricating film is easier to maintain. Thanks to this innovative technology, we were not only able to achieve the required wear service life, but even surpassed it. Additional design changes to the transmission were no longer necessary. In addition to improved wear protection, Castrol PD technology also achieves a reduction in friction coefficients – even when exposed to pressure, vibration and shock load. This can optimize the transmission efficiency, meaning maximum performance both on the road and in demanding terrain.

False brinelling is among the main causes of bearing wear PD technology reliably protects against false brinelling in all of its existing forms.

False brinelling is among the main causes of bearing wear PD technology reliably protects against false brinelling in all of its existing forms.

Fighting bearing wear

As the key component of every wheel, rolling bearings are among the most widespread and most important machine components. They are used in both the new mobility concepts and in traditional vehicle construction. Problems in roller bearings automatically affect the entire wheel and therefore on the entire vehicle. Among other things, these problems include idle marks, also called false brinelling. This wear phenomenon is caused by micro-movements when the vehicle is standing still. During transport of vehicles aboard ships, by road or by rail, vibrations of the ship’s diesel or from railway crossings can cause damage and early failures of the components. In these micro-movements, the lubricant is pushed to the side – especially in cold weather. Low temperatures in particular pose a special challenge to the flow behaviour and thus the lubricating ability of the lubricant.

Castrol developed a lubricant which masters precisely this challenge. In interaction with other important product components, PD technology reliably protects against false brinelling in all of its existing forms. With the help of our specially developed high-performance lubrication grease, the protection against false brinelling can be significantly improved and idle marks are significantly reduced both in number and form. This protects the bearing effectively against wear and it extends the service life significantly.

Stop safely in any situation

The function of the parking brake is not only there to keep the vehicle in the desired parking position, but as a redundant system it also makes a decisive contribution to getting the vehicle to stop in an emergency situation. Many systems, which up to a few years ago were still only working mechanically, are now electronically controlled – also in vehicles. In particular, the modern generation of electro-mechanical parking brakes presented some problems for car manufacturers. The braking forces for the parking brake must be neither too high nor too low. In addition, the forces to control the parking brake react very sensitively to temperature fluctuations. However, the braking force has to lead to a uniform slowing-down at all temperatures. The lubricant is an important component of the brake control system. The risk of brake peaks is high if the viscosity-temperature characteristics of a standard lubricant are inadequate. The brake would either react too strongly or too weakly. Therefore, a particularly smooth lubricant is needed. Castrol’s EPDM-compatible hybrid lubricant – a combination of grease and paste with a special base oil and selected solid lubricants – not only meets the required operating torque of the brake, but it also neutralizes the additional inertia of the electro-mechanics, and compensates for the reduced performance of the battery at low temperatures. This ensures a secure grip in every situation

Lubricants in a most critical endurance test

Rugged terrain and extreme temperature ranges: collaborating on a project such as the Mars rover is a special experience and challenge. In this application it was not only necessary to withstand extreme conditions such as temperature fluctuations or pressure differences, but also to ensure compatibility with plastics and other materials as well as a high performance reserve, media resistance and extremely low evaporation behaviour.

In addition, the application could obviously not be tested under real conditions on Mars… However the lubricant used had to pass a variety of practical and highly challenging tests in the laboratory in order to ensure that the functionality of these extraordinary applications was 100% guaranteed.

Castrol offered a product from the Braycote series, the development of which started at the same time as the NASA space program. Thanks to their perfluorinated organic compounds, Braycote lubricants are particularly resistant to external influences and are characterized by extreme chemical resilience, exceptionally high load capacity, and corrosion resistance. In addition, they are also convincing at extreme temperature ranges from -80 to 200°C, as well as with their excellent vacuum suitability according to NASA SP-R-0022A of less than 0.05 weight percent loss. In addition, they have an excellent lifespan due to the inertness of the perfluorpolyethers (PFPE). Castrol products are still used today on the Mars rover and on the International Space Station.