Lightweight Rotational Axis for Increased Productivity

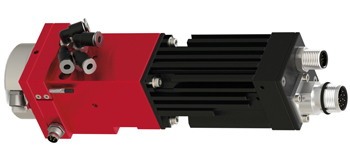

Afag is introducing the new electric rotational axis RA-40, a solution that allows unlimited rotational movement and simultaneous electrical gripper control. The proven SE20 rotational axis technology has been supplemented with the electrical rotary feed-through for the RA-40. Adapter plates, which were previously required for attachment, can thereby be saved, thus reducing the moved mass.

by Cesare Pizzorno

The rotational axis RA-40 produced by Afag, a primary supplier of quality components in the areas of feeding, handling and transport, is the evolution of the proven SE20 system. The tested set of transmission devices, from motor to output flange, up to backlash-free gearbox or hydraulic rotary joint, is indeed the beating heart of the rotational axis. In addition to the electrical rotary feed-through, which includes five independent feed-throughs with a permissible peak current of 2 A, each the RA-40 is also available to order featuring a fluid rotary feed-through. The fluid feed-through is available in two different expansion stages: double, or quadruple upon request. The backlash-free Harmonic Drive gearing ensures particularly high rotational axis repeat accuracies. With a gearing ratio of 30:1, users can achieve a maximum speed of 280 rpm. For applications that require extra torque, the 50:1 gearing ratio achieves a peak torque of 4 Nm.

A thought through design for improved cycle times

As a result of the new, angular design, users can fix the axis directly to the standard Afag attachment grid. Adapter plates, which were previously required for attachment, can thereby be saved. This reduces the moved mass and makes the system quicker. The width of the module is merely a compact 41 mm. This means improved cycle times and greater customer benefit, in particular if it is used as a C-axis for handling systems. For increased accuracy, the direct position output to vision systems as well as for applications with safely reduced speeds, an additional encoder in the axis is available as an option. Both pneumatically and electrically driven grippers can be supplied via the RA-40. The combination of the RA-40 rotational axis and the Afag EU-12 or EG-12 gripper is offered as an ideal electrical rotary gripper unit. Fast and powerful gripper motions with unlimited rotational movements are thereby carried out without compressed air or interfering hoses and cables. The gripping times are 70 ms. A 180-degree axis rotation only requires 150 ms. These values provide an optimal requirement for particularly fast pick & place cycles.