Linear guides for plastic blow moulding machines

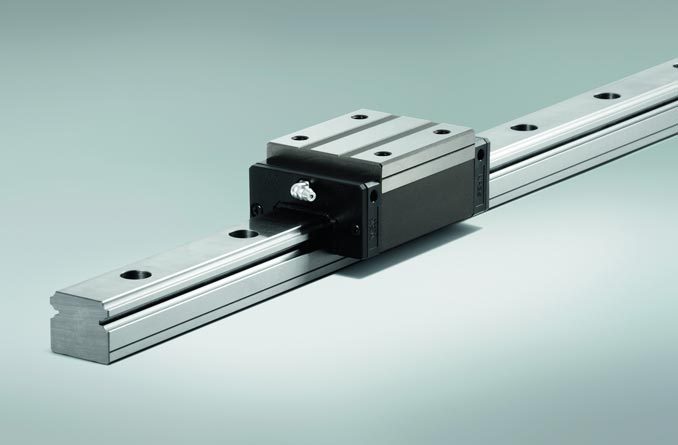

A manufacturer of blow moulding machines replaced its linear guides, which were used to move the mould platens, with the NH series from NSK.

As blow moulding machines operate with fast cycle times and high clamping forces, any wear to key components such as linear guides can be extremely detrimental to the manufacturing process.

NSK carried out a full assessment and failure cause analysis. Once the investigation was complete, NSK discovered there some very minor alignment errors but that these were not the principal cause of damage to the guides. At the same time, NSK technicians established that the load factors given by the linear guide supplier had been calculated using a method which produced results quite different from the values calculated using industry-standard ISO formulae.

The recommendation was made to replace the existing guides with equivalent ones from the NSK NH series, which offer higher load capacity and very long service life due to their optimised design, especially in cases of dynamic stress, overloading, impact loading and shock loading. These effects are often unavoidable in blow moulding systems. For the NH series, the relevant load factor values are calculated based on ISO standards, which is not always the case for linear guides. Very often, values are calculated from tests which have not been made under ISO conditions. The values may appear to be better, but for NSK, a comparison based on the ISO standard is the correct method and one that users can replicate. The switch to NH guides led to a significant reduction in the wear susceptibility of the clamping units.