Long Life Sealed Roller Bearings for Rolling Mills

The four-row tapered roller bearings developed by NSK offer a long service life in the harsh working conditions of rolling mills. The sealed design prevents water from penetrating into the bearing while reducing the consumption of grease as well as the risk of contaminating the environment.

by Elena Magistretti

NSK has developed its latest four-row tapered roller bearings for rolling mills to offer a number of class-leading performance and environmental benefits. The new roller bearings use newly developed, water-resistant grease that is fully sealed into the bearing. Service life is typically doubled in challenging conditions such as those where there is a high risk of water penetration. In addition, the sealed design means that grease consumption is far less than that exhibited by a conventional ‘open’ bearing, while the risk of contaminating the environment is greatly reduced.

The new bearings can withstand heavy loads, high speeds and temperatures

Roller bearings that last longer is one of the primary demands of rolling mills. NSK’s new long-life, four-row, sealed tapered roller bearings with new AQGRD grease can satisfy this requirement.

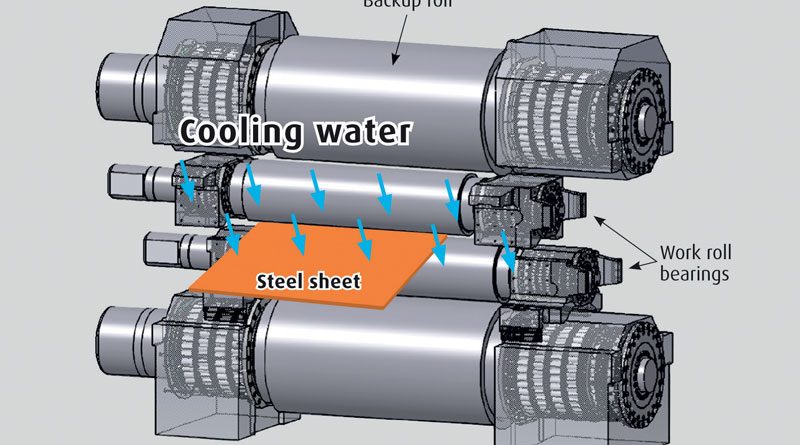

Rolling mills typically use pairs of work rolls to roll slabs of steel or other metals into specific shapes, such as sheets. This work is particularly demanding on the bearings, which have to bear heavy loads at high speeds and temperatures, and endure constant exposure to water sprays and metal particles. These severe operating conditions can lead to premature bearing failure due to flaws such as flaking.

Flaking occurs when fatigue causes small pieces of bearing material to separate from the smooth surface of the raceway.

This effect creates coarse regions that eventually make the bearing inoperable.

The water-resistant grease prevents bearing damages

The major innovation designed to help combat such issues is the newly developed AQGRD water-resistant grease.

Optimised grease composition creates a thicker oil film and protective layer between the raceway and rollers, inhibiting direct contact without lubrication, as well as preventing corrosion. Rust prevention is important as harmful defects such as flaking, which compromise bearing life, stem from areas of corrosion. Ultimately, longer service life reduces maintenance costs and increases operational efficiency. Moreover, since the bearings need less frequent replacement, they help to minimise carbon footprint and resource consumption.

Aside from the long service life benefits, reduced material and energy consumption will also result in relation to the replacement cycles of conventional bearings, which in turn helps to lower CO2 emissions.