Machining one-of-a kind pieces in series

Users of CNC lathes and milling machines are often faced with a difficult choice: to opt for the greatest possible variance of parts or for large volumes? An innovative solution now makes it possible to achieve both, while at the same time lowering the threshold for automation. We are talking about servo-controlled gripper jaws, in which brushless DC servo motors with integrated speed controller from Faulhaber provide the necessary precision and reliability.

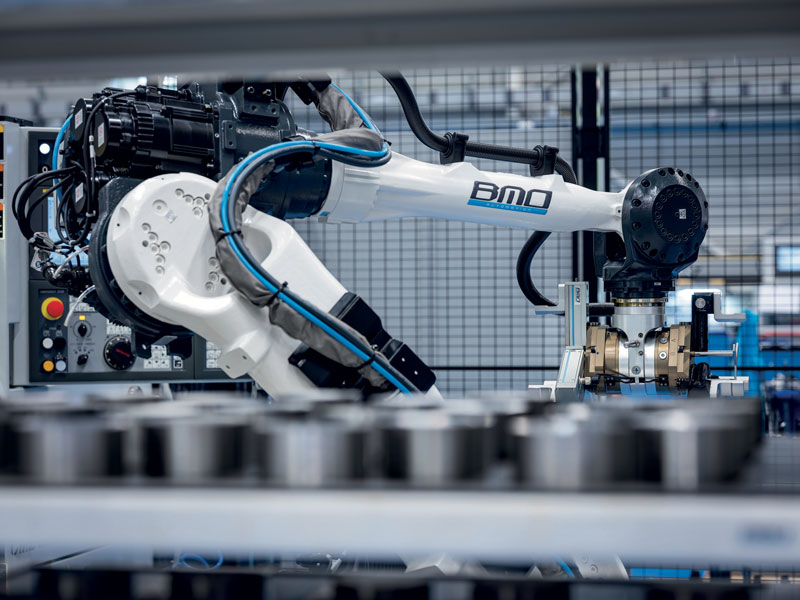

Dutch company BMO Automation has been researching more efficient loading systems for CNC lathes and milling machines for more than a decade. Here is an interesting example: in cooperation with FAULHABER, a servo gripper has been developed for use in robot cells for the automated loading and unloading of CNC lathes and milling machines. With its robot cells, BMO Automation enables the automated production of workpieces of different sizes from batch size 1 onwards.

Thanks to the servo gripper, the development of which was carried out jointly by the two companies, flexibility is significantly increased.

High mix and high volume: the turning point

The margins in the manufacturing of small quantities are generally higher than in mass production. At the same time, however, it is more personnel- and cost-intensive if the workpieces need to be manually loaded between individual turning and milling processes. Thus, a solution that achieves both high variances as well as high volumes when using CNC lathes and milling machines in the metal and plastics processing industries is a game changer. For their approach, BMO Automation combines the advantages of pallet automation with the option of also being able to load individual workpieces fully automatically. From the principle “high mix – low volume” thus becomes “high mix & high volume”.

The servo gripper automatically adapts to format change-over

Servo-controlled gripper jaws whose precision and reliability are guaranteed by Faulhaber drives, make this possible. In the servo gripper, a Faulhaber motor drives a gear spindle that is part of a linear guide system. The gripper fingers, connected to the guided blocks, thereby move to the desired position for the product that is to be loaded into the CNC machine. The dimensions of the workpiece can change following the turning or milling process. Here, the servo gripper automatically adapts the position of the gripper fingers and does so without changing the loading and unloading cycles. As a result, it is not necessary to change the gripper.

A software tool was used for the selection of the appropriate motor

The appropriate motor was selected using the Drive Selection Tool on the FAULHABER website. At the same time, BMO Automation received support from FAULHABER, for example, in checking the script files for communication with the BMO Intelligent Control Software.

Development lasted approximately one year, including a two-month test phase with reference customers. The biggest challenge was in integrating a reliable solution that is available in the smallest possible dimensions with a low weight and thereby has a minimal impact on the load capacity of the robot.

Faulhaber’s very compact and yet high-performance solution in both the mechanical as well as electronic part fully convinced its customer.