“Made in Italy” ball transfer units for loads handling

Ball transfer units are used for linear handling of loads. RGPBALLS boasts a strong specialization in this field, offering different materials, coatings and configurations to meet the needs of various applications: from the handling of small to heavy loads in harsh conditions of use.

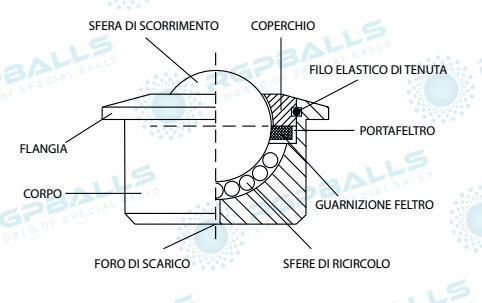

RGPBALLS designs, manufactures and sells ball transfer units. These multidirectional systems for the linear movement of loads are composed of a large ball that rotates on a defined quantity of small diameter balls, all enclosed in a hemispherical seat. Thanks to the care with which the machining of the various components is carried out, the friction is particularly low, thus allowing the force required to move the loads to be significantly reduced. The production range includes ball transfer units made of different materials such as steel, stainless steel, stamped sheet and plastic materials. There are also different types of coatings available to preserve oxidation resistance over time. Even the inside balls used can be chosen from different types of materials depending on the final application. In fact, the company offers the possibility of assembling all the components with different materials, based on use.

Different types to meet the needs of all applications

RGP mainly produces units with housing in hardened steel turned steel from bar which are normally used in presence of heavy loads, strong stresses, impacts and severe conditions in general. For high flow rates, similar versions are available, specially designed for these applications.

Units with pressed steel sheet components are preferable in applications for smaller loads. They combine good smoothness with adequate flow rates, allowing a lower final cost. Units with plastic components are preferable in applications for smaller loads. They are suitable for use in contact with salt water or chemicals, in the food, chemical, electronics and pharmaceutical industries. RGP ball transfer units can be positioned in any orientation, in addition to the conventional one, but some versions intended for specific applications are suitable for conventional use only. The operating temperature is normally between -20 ° C to +100 ° C (+70 ° C continuously and +100 ° C intermittent). Temperatures up to +150/200 °C are tolerated by eliminating the internal dust seal. For use at high temperatures we usually recommend the version with all components in AISI 420C stainless steel, without felt gasket.

Technical drawing of ball transfer units.

The Cinisello Balsamo headquarters employs 70 people working on an area of approximately 10,000 m²

High precision customized balls

In order to meet the ever-increasing demands of its customers, RGPBALLS just built a brand new production department in the headquarter in Cinisello Balsamo (MI) dedicated to the MADE IN ITALY production of custom balls with unconventional diameters. The entire department has grinding and lapping machines as well as sorting machines for the diameter and machinery for surface micro-finishing. The company is now able to produce even batches of a few pieces, compared to standard productions, while maintaining a very high degree of precision. Thanks to the innovative sorting through eddy currents, we are now able to detect small internal defects in the material, effectively guaranteeing quality and accuracy never achieved before. The diameters produced must meet the highest standards, being a production dedicated only to specific applications.