“Made in Italy” Quality for Food & Beverage Fittings

The Tierre Group range of fittings, entirely produced in Italy for food & beverage applications, meet the main national and international certifications. The same attention to the level of hygiene also applies to the lubricants used in the assembly of components.

Today, more than ever, it is essential to base the restart of our country on the value of Made in Italy. This in order to give a strong message to the rest of the world: Italy is now recovering and wants to guarantee, as it has always done, the quality and reliability of its unique and irreplaceable products worldwide. Thanks to its strong experience in the field of fittings and accessories, at Tierre Group is aware of the importance to focus on the “Made in Italy”. Today the company deals not only with distribution and supply, but also with production, and has chosen Italy as its production site.

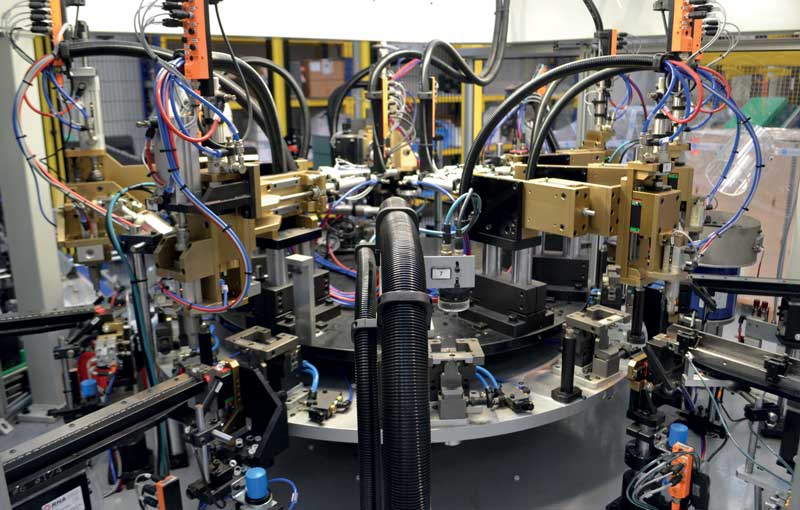

Production facilities, located in Brescia and built in the year of the twentieth anniversary of Tierre Group, represents the “summary” of the company policy: surrounded by greenery, in the heart of the industrial Italy, it has a highly technological soul. Production machinery, consisting of state-of-the-art automated and robotic machinery, guarantee a full quality control, and is connected to an efficient and advanced internal management system and to the automatic vertical warehouses. Innovation pervades the company’s entire supply chain, up to the stock management, carried out according to innovative programs and methods.

The XVR range of stainless steel fittings from Tierre Group.

To avoid possible contamination, the lubricants used for assembly are suitable for contact with food.

Production machinery consists of state-of-the-art automated and robotic machinery.

Tierre Group headquarters in Cormano (MI).

Fittings for the food & beverage sector meet the highest standards

Tierre Group produces fittings for “food & beverage” applications with the utmost care and in compliance with the highest quality standards. Fittings are small-size components, but they are extremely important in the design of safe and secure systems, intended to convey fluids in contact with food.

With respect to this, the choice of “Made in Italy” was fundamental. The production process of all the fittings manufactured on-site has been carefully designed to safely produce components intended to come into contact with food and drinking water.

The national and international certifications obtained by the Tierre Group do not derive from simply formalized procedures, they are the result of careful and continuous developments for the highest possible quality. A significant example: to avoid possible contamination, the lubricants used for assembly are suitable for contact with food, always, for each type of fitting produced, even for those fittings that are not related to the food industry.

The XVR range, made of stainless steel, the HFR range, made of brass with TEA + treatment, and the LFR range, made of brass with a very low lead content, have obtained the NSF certifications and are compliant for contact with food and drinking water according to national (DM 174) and European (EC 1935). Regulations. Guaranteeing high-level hygiene standards means taking people’s health seriously. To do this Tierre Group has involved all the players in the production chain, has carefully selected the construction materials and has implemented the traceability of every single element on a daily basis, whether it is produced internally or purchased, as in the case of some components.