Maximum Resistance in the Most Severe Conditions

ROTEX® flexible couplings from German company KTR, distributed by Mondial and used in the cutting devices of various types of harvesters, meet the stringent requirements imposed by the harsh conditions in which agricultural and earth-moving machines operate: wind and weather, sand and dirt, vibrations and shocks.

The agricultural machinery sector is becoming increasingly demanding. The conditions in which machinery operates are particularly harsh: wind and weather, sand and dirt, vibrations and shocks require components that are able to withstand the most critical conditions. For a long time Mondial has been operating in the field of agricultural machinery, offering specific products for every need such as freewheels, chains, actuators, roller and needle cages, couplings.

Different versions with targeted treatments

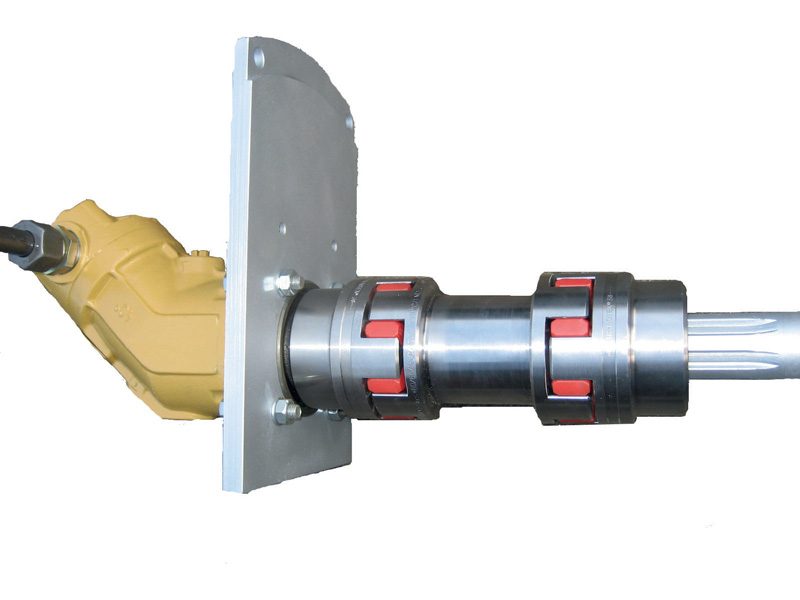

As far as the last range is concerned, Mondial offers ROTEX® flexible couplings from German company KTR. These couplings are used in the cutting devices of different types of harvesters (combine harvesters, sugar beet harvesters and so on).

In the agricultural machinery sector control systems and their components must meet specific requirements; these machines often operate in contaminating environments, which generate high wear and tear. ROTEX® couplings have surface treatments that are adapted to the specific application. For example, a version with a standard grooved profile according to DIN 9611 is available for use in conjunction with a power take-off. This version has been specially developed for mechanical auxiliary drives that can be connected to agricultural machinery such as tractors, mulchers and presses. Mondial offers the version with grooved profile also for applications on machinery such as pumps and compressors installed on earthmoving machines.

An in-house structure formed by technicians and experts

Each type of application has its own specific product. It can be difficult for the designer to disentangle the many offerings available to him. That’s why Mondial has an in-house team of engineers and technical experts. This is an unusual choice in the panorama of component distributors, but it allows Mondial to have a direct line with the designers of its client companies, supporting them in the study of solutions with the best quality-price ratio for the type of application to be realized and contributing to the development of innovative applications.