No More Sequential Production, Adaptive Machines are Welcome

To achieve full flexibility, all functions (including PLCs, HMIs, I/O, motion, robots, intelligent asset transport systems, vision systems, safety, IIoT connectivity and diagnostics) must be under the same development and control environment. Technologies, when integrated, generate a new category of ‘adaptive’ machines, lines and factories.

Manufacturers and distributors of consumer goods are faced with a market that demands personalized products, immediately.

Commerce has become natively electronic and omni-channel, so even when appropriately influenced by artificial intelligence, today’s market dynamics are characterized by changing consumer demands that lead to SKU (Stock Keeping Unit) proliferation, smaller lot sizes, the extreme of mass customization, and shorter product life cycles. Finding machines and skilled labor to achieve the flexibility and efficiency needed to cost-effectively meet these requirements in both factories and logistics hubs is not a challenge that can be met without shaking up and changing the very paradigm of manufacturing as we know it.

What can be integrated today

Each new piece added to the integrated control ecosystem opens up new possibilities and unlocks additional performance levels for Italian machine builders and manufacturing. An advanced software solution enables and simplifies factory design, implementation and use, so as a single mind, single application on a single network enables synchronization and flexibility that leads to unprecedented performance, cost reductions and scalability.

In harmony with the whole, i.e. adaptive

This set of technologies, when integrated, generates a new category of adaptive machines, lines and factories, equipped with a new level of flexibility that makes them able to produce, in an economically sustainable way, ever smaller batches and customized products. These factories, instead of being forced into rigid sequential processes, adapt the route and processes to the required product, exchanging all planning and production information with the company to implement digital strategies and make the entire factory adaptive. Being integrated also means being safer and more collaborative with the operators on the line, who now have everything at their disposal to better understand and manage all the activities in production.

Everything integrated by design point of view means being able to use information from individual devices, entire machines, and process data to simulate and optimize machine behavior and production cycles. It means being able to monitor the health of the lines and intervene when and where needed, optimizing total production. From the operators’ point of view, total integration means the new ability to see what is needed to understand what is happening in an immediate, understandable and intuitive way, without having to be a specialist. Operations can be moved to more comfortable and secure environments, thanks to guaranteed remote accessibility on any device, including mobile.

Latest added technologies

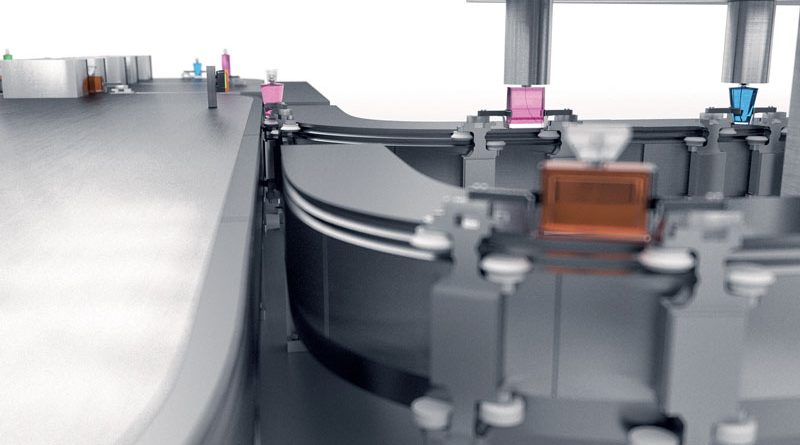

To the traditional automation made up of controllers, operator panels, motors and drives, sensor technology and safety devices, three important categories of intelligent products bring great advantages to the factory floor, especially when combined. The vision system – integrated of course, as are all moving parts of the machine – makes it easy for machine builders to ensure ever-higher quality and productivity. Cameras with ultra-high-performance sensors and optics and an extensive range of illuminators ensure maximum throughput and comprehensive information to ensure performance and quality in production. The latest generation of asset transport systems, also integrated, where independent trolleys run along production lines synchronizing themselves with the other moving parts, reacting intelligently and leading to optimized and customized production, at mass production times and costs. Robots controlled directly by the machine CPU. Machine builders will be able to easily integrate anthropomorphic robots, SCARAs, deltas or palletizers. Especially important in situations where close coordination with all other moving parts is required, such as in pick and place applications, the integration of robotics and the use of a common network brings benefits in terms of synchronization, accuracy and safety. Since the robot no longer requires a dedicated controller, all interfaces between the machine and the robot are eliminated, reducing the line footprint as well. Finally, Simulation and Digital twin are the technology needed to have a complete virtual prototyping of the system. Thanks to them, time and costs of machine design, production scheduling, but also the risk of the investment are reduced to a minimum.