Protecting from Corrosion with Dedicated Products

Winkel has recently extended its supply range for corrosion protection by making available, for example, Duralloy and cyanide-free zinc treatments. These bearing series are successfully used in the shipbuilding industry, but also in the food industry and in washing and packaging plants.

In recent years, the shipping and nautical industries have gained increasing importance, thanks not only to the growth in the transport of goods by sea, but also to the growth in cruises and private boating. Cruise ships are becoming more and more advanced, not only as regards technology, but also in terms of comfort, and the same applies to smaller vessels. This has led to greater demands for automation with the use of components derived from the mechanical industry, but suitable for use in the particularly aggressive marine environment. WINKEL exploits the experience gained in the naval sector by offering a range of dedicated components. Today, three different bearing designs and two slide profile designs are on offer, as well as Vulkollan or Polyamide coated roller bearings with aluminium profiles for light loads.

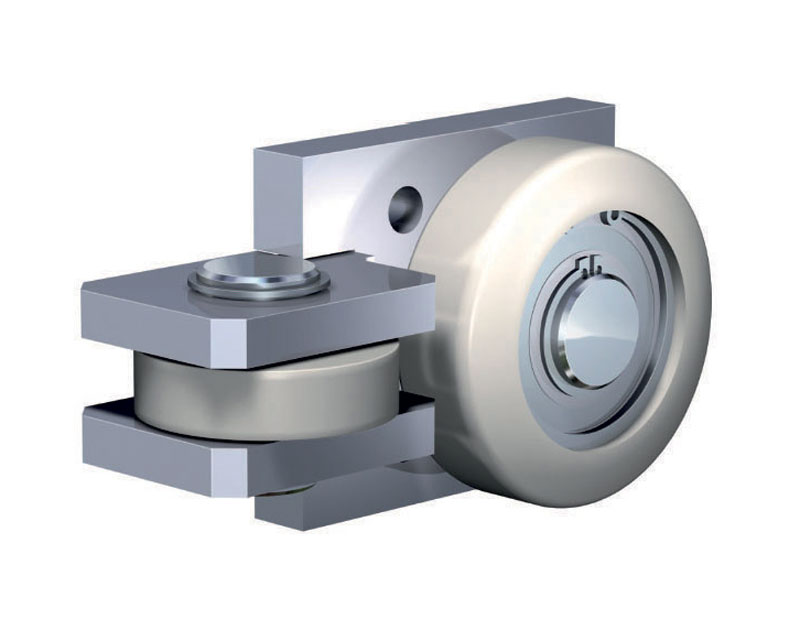

Bearings made of stainless steel and with Duralloy treatment

The range includes bearings without rolling elements, which use self-lubricating slewing bearings and can therefore also be operated in immersion, and bearings with stainless steel rolling elements (balls), which are suitable for use at high speeds and with low friction. These series are also successfully used in the food industry, in washing and packaging plants. In the course of 2020, the profile type was changed from rolling to laser welding in order to ensure better application accuracy. All WINKEL bearings in the V11/2018 general catalogue are available with Duralloy surface treatment. The Duralloy coating consists of applying a 99% pure chrome surface to the bearing in order to create a bond with the molecular structure of the bearing base material: this also ensures that the coating can be detached from the base material. This treatment takes place at a low temperature and therefore does not alter the structure of the material or the geometric shape of the product. In addition to excellent corrosion protection, this coating also protects the outer surface of the bearing from mechanical wear and therefore increases its service life even when subject to high fatigue stresses.

Profiles and bearings resistant to corrosion and high temperature

All WINKEL bearings in the V11/2018 general catalogue are available with a ZFC surface treatment. This treatment consists of coating the outside of the bearing with a zinc treatment and sealing using a cyanide-free process. This treatment has properties such as high corrosion resistance, greater than 720 hours in a salt spray environment; resistance to high temperatures; excellent ductility; less hydrogen embrittlement; excellent receptivity to Cr III finishes and finishes in the total absence of Cr. In order to achieve a fully corrosion-resistant linear guidance system, it is necessary to supply not only the exempt bearing, but also the relevant guidance profile. WINKEL can supply different solutions; from the stainless steel profile, available in four different sizes, to the profile with a corrosion-resistant coating. All WINKEL profiles are also available with corrosion resistant treatment even in machined versions. The following coatings are available: galvanic zinc plating up to a maximum profile length of 4 m; hot-dip galvanising up to a maximum profile length of 12 m. This coating creates a protective layer, which is then applied to the profile. This coating creates a protective surface layer with a thickness of 0.1 to 0.3 mm which does not impair the functionality of the profile-bearing combination; as it moves, the bearing follows the profile coating without causing it to detach.