Reducing maintenance in continuous casting machines

NSK SWR (Super Wear Resistant)) spherical roller bearings overcome the challenges of continuous casting machines. These advanced bearings provide superior wear resistance, flaking life and outer ring toughness than standard counterparts made from AISI 52100 bearing steel. This extends their operating life with a positive impact on maintenance costs. The result? 140,000 euro of annual savings in a steel manufacturing plant.

Bearings used in continuous casting machines have to endure arduous operating conditions that include high temperatures, heavy loads, ultra-low speeds, water/water vapour and scale. As a result, bearing failures such as wear, flaking and fracture are commonplace, prompting increasing numbers of steel manufacturing plants to adopt NSK SWR (Super Wear Resistant) spherical roller bearings. These advanced bearings provide several times more wear resistance, flaking life and outer ring toughness than standard counterparts made from AISI 52100 bearing steel.

The case study: bearing failure in continuous casting machines

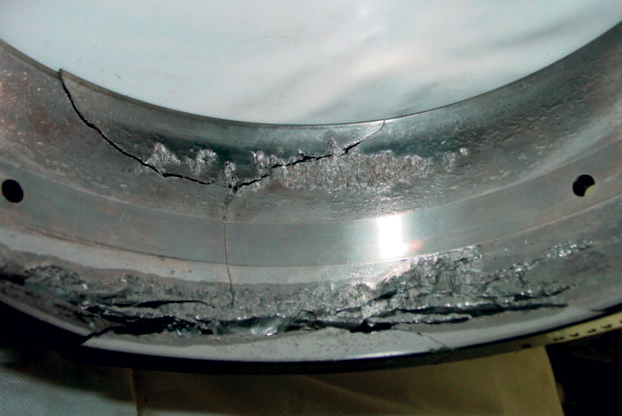

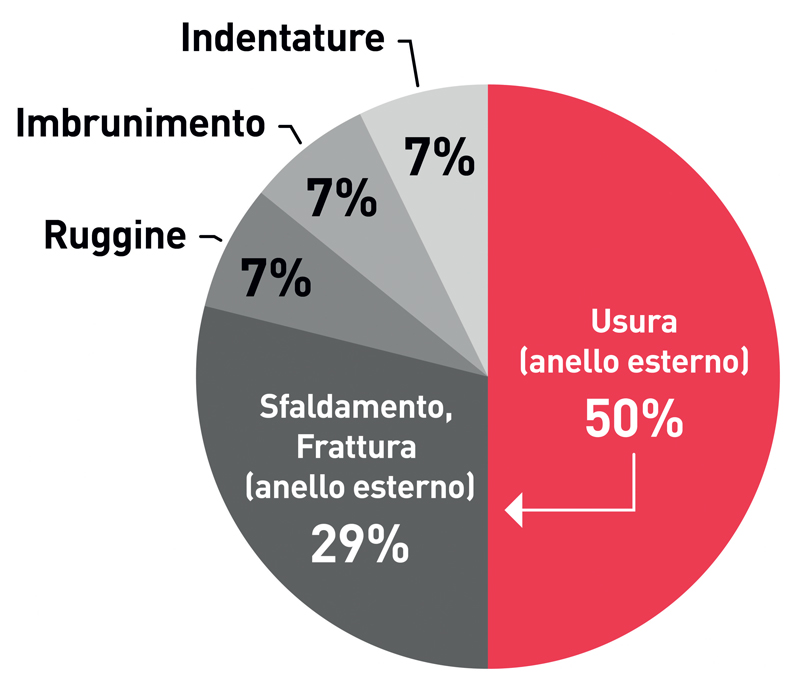

NSK SWR series have been fitted in an international steel manufacturing plant that was previously experiencing regular bearing failures in a continuous casting machine. The machine produces steel slabs, a process involving the application of heavy loads that were compromising the life of standard bearings due to wear and fatigue. Indeed, the average life of the bearings was just 40-50 weeks. NSK’s expert engineers noticed that the failure modes were consistent with others seen in continuous casting machines featuring standard spherical roller bearings. NSK’s bearing condition report contained a recommendation to adopt SWR series spherical roller bearings, which take advantage of a specially developed steel with far higher wear and fatigue resistance. Proven in continuous casting applications since 2001, the wear resistance of SWR bearings is three times that of AISI 52100 bearing steel, while both flaking life and outer ring toughness are five times greater. Furthermore, NSK SWR bearings can replace standard SRB bearings in continuous casting machines without modifying the axle, and work effectively with or without seals. Minimised outer-ring friction contributes to extend bearing life. This factor is important as friction due to differential sliding can promote uneven wear, flaking and fracture, which together constitute around 80% of defects found in the outer ring of spherical roller bearings at steel manufacturing plants.

Annual savings of € 140,000 thanks to a longer operating life

NSK suggested commencing a durability trial with SWR spherical roller bearings. Such was its success that the bearings delivered 60% longer operating life, leading to impressive annual savings of ?140,000. This total arrives from the elimination of both downtime due to bearing failures and labour costs for bearing replacement. Results of this magnitude are easily achievable in continuous casting machines, where standard spherical roller bearings are simply not robust enough to withstand the harsh operating conditions. In these applications,

An App to help users diagnose bearing damage

Maintenance engineers and technicians tasked with troubleshooting machinery or equipment featuring rolling bearings can take advantage of NSK’s Bearing Doctor app. This effective tool provides information about correct bearing handling, mounting, lubrication and maintenance to prevent premature failure. The app also includes many images and sound clips to help users diagnose bearing damage and possible causes.