Significant Reduction in Installation Time and Costs

Assembly of I/O modules without a control cabinet directly in the field is the current trend, and it has various advantages such as lowering installation time and costs. Therefore, Phoenix Contact has added a safe I/O box to its proven Axioline E I/O system in the IP67 degree of protection. Now, safety-related signals up to SIL 3 and PL e can also be measured and output.

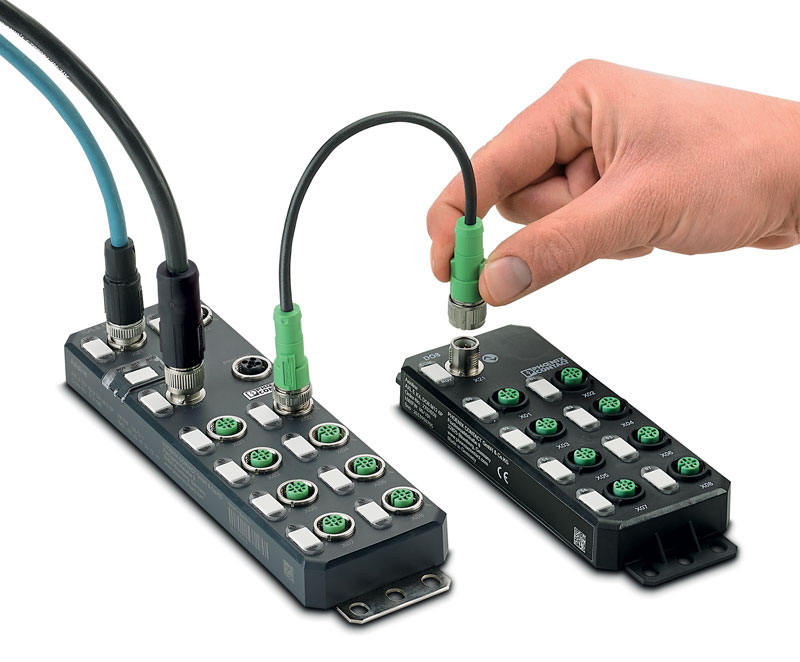

During development, many machine builders and systems manufacturers are frequently confronted with the question of whether sensors and actuators installed in the field should be connected to the control technology in the classic manner through I/O modules installed in junction boxes. Alternatively, they can be connected through I/O modules mounted directly in the field with IP65/67 degree of protection. There are many different opinions about this, because each approach has its advantages and disadvantages. While the junction box variants unlock a high level of granularity, the IP65/67 solution reduces the assembly and installation costs and effort significantly. So what are the broad requirements that manufacturers of machines and automation systems have for the integration of the sensor-actuator level? On the one hand, a high level of flexibility is needed to be able to react quickly to customer-specific requirements, because usually no two series production machines are the same. This first point is therefore also a major issue in this mechanical engineering segment. On the other hand, there is the saying: “Time is money”. This means that machine builders and systems manufacturers expect a simple and fault-preventing installation. This is where field devices in a higher degree of protection show their strengths. Since they can be installed directly on-site in the machine or system, there are short cabling paths, and routing the wiring needed is transparent. Moreover, the pre-assembled M12 cables contribute to reducing the time needed. If the modules need to be replaced during running operation, the user needs precise diagnostics with the location of the fault and its cause so that they can ensure the availability of the application (figure 1).

Safe up to SIL3, SIL CL3, and PLe

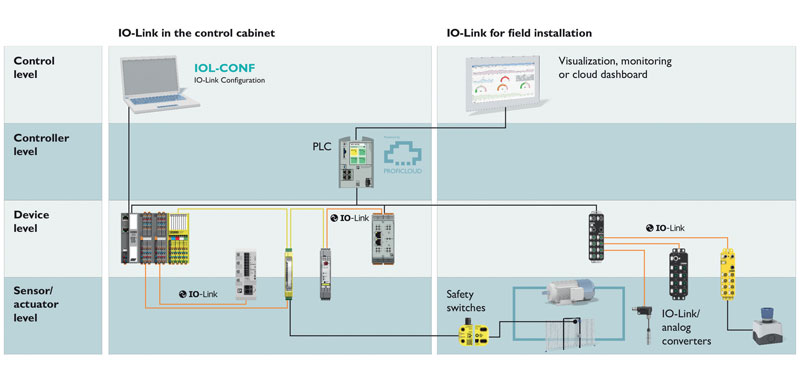

The arguments listed are the reason why the number of users of decentral I/O modules with a high degree of protection has been growing for years. With the devices from the established Axioline E product family, Phoenix Contact covers a huge range of the signal types and networks required here. At the same time, the Axioline E modules have proven themselves as Ethernet specialists for installation in the field. This is because the block assembly I/O system, which can be attached directly to the machine without a control cabinet, supports all Ethernet-based communications protocols. This allows a high degree of flexibility. Its digital inputs and outputs allow the implementation of most requirements. Other types of signals are coupled through the installed IO-Link master (figure 2).

Until recently, users were still confronted with the challenge that safety-related signals could not be measured and output with the system. Therefore, a parallel solution for functional safety was required. It was implemented either using separate safety relay modules in a central control cabinet or through an additional safety controller, and both alternatives involved time-consuming and costly parallel wiring. This is no longer necessary, because the Axioline E product range has been expanded with the secure I/O box Axioline E Safe with IP67 degree of protection. The module can record and forward safety-related signals, such as emergency stop or light grid signals. Depending on the configuration and wiring, a safety level of up to SIL 3, SIL CL3, or PL e can be achieved (figure 3). Along with its eight safe inputs and four safe outputs and an IO-Link interface, the I/O box contains additional features. For example, it does not have a switch for setting the safety address. The address is now assigned via the respective engineering tool or controller. For fast device replacement, you can use a separate flash drive for the safety address as an option. The I/O box also stands out, thanks to a multilingual disposition: It supports the PROFIsafe protocol and can be operated with PROFIsafe-capable safety controllers. The integrated SafetyBridge Technology (SBT) also allows it to be integrated into nearly all automation networks (figure 4).

Network and control-independent implementation

If the machine’s PLC is understood to be a central element, a solution with a safe controller has a decisive advantage: The status of all safe input and output modules is available in the PLC. The same is true for all diagnostic information on the safe modules. If, for example, there is a short circuit at an output or an equivalence violation at an input pair, the machine operator is simply shown the fault and the associated visualization via the controller and is given suggestions for troubleshooting. If this does not result in the fault being fixed, then the information is also accessible via remote maintenance solutions. This means that the machine builder can provide the operator assistance remotely. This shortens downtimes and thus increases the availability of the application. The benefit that the combination of decentrally installed, secure I/O modules and safe controllers provides is therefore obvious. But many users are faced with the challenge that not every controller manufacturer offers a safety PLC. In addition, they do not want to pay the higher costs for a safe controller. Moreover, many machine builders develop their own PLC, but do not have the expertise to implement a safe controller. Therefore, their customers are forced to use concepts that are no longer commonly used. The user either has to accept the disadvantages of the classic solution or, say, use a separate bus to transmit the safety data that has to be coupled to the standard PLC. This is done with parallel wiring on the standard inputs or a connection via bus gateways. Both have proven to be complicated and involve additional costs.

Comprehensive diagnostics without additional time and costs

In light of this, the I/O box Axioline E Safe supports the SafetyBridge protocol. An executable SBT system consists of secure input and output modules and what are referred to as logic modules. The I/O modules acquire or issue the secure signals. Furthermore, they are always performing diagnostics by, for example, checking the device for short circuits and cross-circuits, and anti-violations and equivalence violations. The logic module is the central element of the SafetyBridge installation. It generates and monitors the safety-relevant SBT communications protocol and processes the logical connections of the parameterized safety logic. A safe controller is not necessary.

The secure signals that are received or output with the SafetyBridge I/O modules can be forwarded over almost all automation networks, such as PROFIBUS, PROFINET, EtherNet/IP™, EtherCAT®, CANopen®, Sercos III, or Modbus/TCP, as well as all common controller types. It is equipped with an IO-Link interface, like the I/O Box Axioline E Safe, to couple the SBT module to the respective network for data exchange. It is integrated into the network used via the respective IO-Link master. The standard controller handles data exchange between the modules. The PLC programmer has access to the status of all the secure inputs and outputs. Without additional hardware, wiring, or programming effort, they receive information about which safety door was opened or which emergency stop button was pressed. In combination with a visualization solution, the machine operator receives instructions for eliminating the malfunction in the event of an error. This can substantially reduce downtimes which have been caused by functional safety.

About the author: Dipl.-Ing. (FH) Lutz Rahlves, Product Manager Safety in the Business Division Automation Infrastructure, Phoenix Contact Electronics.