Smart Monitoring of Drive Chains

Developed in-house and patented by iwis, the CCM-S (Chain Condition Monitoring – Smart) system continuously measures the wear elongation of chains during operation and gives maintenance staff a timely warning that a chain needs to be replaced: a Maintenance 4.0 – Intelligent chain monitoring solution to avoid downtimes.

by Florian Wimmer

Predictive maintenance is a key issue in the context of Industry 4.0 when it comes to getting the most out of machines and systems. A new, intelligent system from chain vendor iwis antriebssysteme prevents production downtimes resulting from unscheduled maintenance and repairs: It permanently monitors chain elongation and provides a timely warning so that appropriate action can be taken.

If chains stretch and wear as a result of temperature and load or if chains running in parallel have different lengths, even a deviation of one percent from the nominal chain pitch can lead to problems in a machine. To take an example from chocolate production, which places very high demands on chains and chain systems, this could cause the position of the chocolate moulds to change.

This is because where chocolate bars, chocolates or biscuits are being made on a production line, the drive chains used are always subject to very strict length tolerances and tolerances across pairs of chains. The mould conveyor chains have to permanently run in parallel – exact positioning is an absolute must. Systems and machine components must therefore be monitored and checked regularly.

However, by the time the system indicates a need for maintenance or adjustment it is often already too late. Preventive maintenance allows mechanical engineers to react more flexibly and more economically.

Constant monitoring of the live system

This is exactly where the smart solution from the international, Munich-based chain manufacturer comes in.

With the chain elongation monitoring system CCM-S (Chain Condition Monitoring – Smart), users can permanently monitor the elongation of chain drives on the basis of sensors without having to compromise production by interruptions. The patented system measures the elongation of chains during live operation. It enables companies to take early measures by providing maintenance staff with timely information as to when certain measures need to be taken and whether a chain needs to be re-tensioned or replaced. The system’s intelligent data analysis enables service staff to plan service activities and personnel requirements in advance.

Improved machine utilization

According to Florian Wimmer, Value Engineer at iwis, continuous chain elongation measurement offers some decisive benefits for customers; these include fewer downtimes and interruptions to production on machines and systems, which can jeopardize a company’s ability to meet promised delivery dates. Planned maintenance allows staff to react in good time.

And the time needed for maintenance is also reduced because the CCM-S tells the engineer which drive chain needs to be replaced before the system is opened up. The CCM-S system measures chain elongation without any contact and does not actively intervene in the chain drive. The module can be easily retrofitted in a variety of chain applications.

Simple plug and play installation

The CCM-S module is plug and play. It is very easy to install and it is no longer necessary to preset any values or perform any calibration in the application. The module is simply installed in the machine and the system is ready for use as soon as the cable is plugged in.

If the module is installed in an existing chain drive, users can immediately start evaluating the data on wear in the chain drive using either iwis software or IO-Link.

Contactless and without intervention in the chain drive

Once the monitoring system is in operation, it gets on with its job discreetly in the background: Because it carries out precise chain length measurements without contact, the CCM system does not actively intervene in the chain drive.

The system can also take measurements irrespective of the speed. It always records two readings at two different sensor locations, with both readings being taken at the same time.

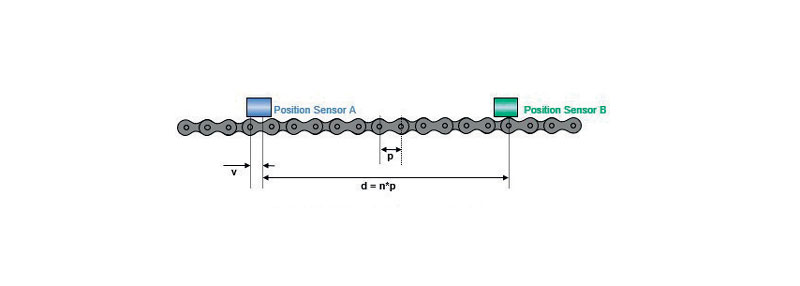

Referring to the figure in the next page, where:

d = defined distance between sensors A and B

n = number of chain links between sensors A and B

p = pitch

v = offset resulting from chain elongation

you will notice that the measured chain elongation is the difference between the defined distance between the sensors (d) and the nominal dimension of the chain (n*p).

The CCM-S returns the ratio between the measured chain length and the nominal length of a new chain. This value is the chain elongation in percent. In the CCM-S, iwis has developed a monitoring system that makes use of the physical principle of induction: the chain rollers move past the coils of the sensor and can thus be identified as a metallic unit.

Problem-free retrofitting

The developers at iwis wanted to make their smart solution as widely applicable as possible and designed the monitoring system for different chain sizes. Since the CCM-S detects only one strand of the chain, it can also monitor duplex and triplex chains.

Thanks to an SLE function (Segment Link Elongation), the system does not only record elongation of the entire chain in the system. Using the SLE function, the entire chain can be subdivided into individual segments.

These are measured individually and assessed for differences from the average chain elongation.

To achieve this, magnets must be attached to both sides of the outer plates of the chain strand in order to define a start/end point. This allows the system to generate a bar chart showing the elongation of individual chain segments.

Author: Florian Wimme is Value Engineer at iwis antriebssysteme.