Smart Sensors for Oil Refineries

Sick offers smart sensors and secure connections to help petrochemical companies make their plants “smart”. One of the many solutions addressed to this sector is the MCS300P photometer, characterized by an innovative analysis technology for gaseous and liquid media.

di Elena Magistretti

Thanks to a wide portfolio of sensors and measurement technologies for any industrial sector, SICK is able to offer an important contribution also to petrochemical companies.

In spite of the great push that came from super-depreciation plans in 2017, recently extended to 2018, the highly traditionalist refinery context still seems far from the concept of Industry 4.0.

This is true despite the fact that the revamping of plants with the implementation of new sensors and approaches is much simpler than one might think. This, in short, is Sick’s point of view.

During the last edition of the mcT Petrolchimico Mostra convegno, which took place in Milan at the end of November, Sick described the potential of new-generation smart sensors, considering various aspects including the management of advanced diagnostic data and secure remote accessibility, which maximize measurement availability and ensure process optimization.

With the new solutions, measuring is always under control, also reducing costs and intervention time.

Thanks to this potential, addressing problems that arise as a result of a possible sensor or complete solution malfunction is much cheaper and faster, avoiding long plant shutdowns.

Data security is not put at risk

One of the main obstacles to the adoption of innovative solutions concerns data security and the fear that the interconnection of different devices and remote connections can damage production.

As a matter of fact, the direct interface of a sensor with the cloud can be totally secure. There are procedures, strategies and tools that allow you to achieve this without compromising security, such as when operating on a remote analyzer, ensuring transparency on what is done and how.

The advantages of using an Industry 4.0-oriented solution are obvious and the tax benefits are interesting.

Innovative analysis technology

for gases and process liquids

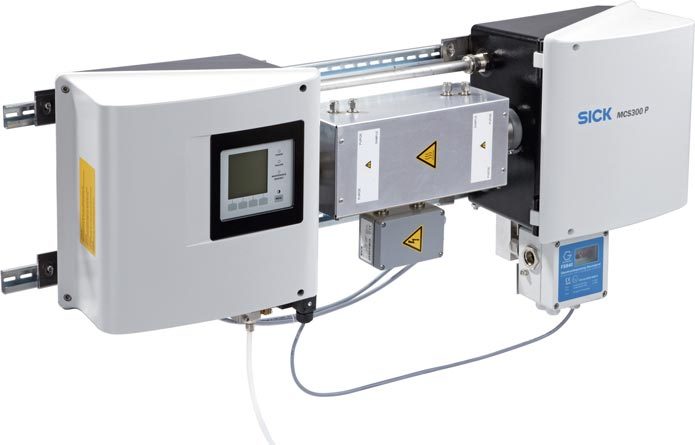

One of the many solutions presented by Sick at the Mostra convegno is the MCS300P photometer. Thanks to the combination of the non-dispersive measuring method with the concept of interchangeability of the measuring cell, MCS300P detects all active components in both the infrared and visible ranges. The use of two filter wheels allows simultaneous analysis of up to 6 components. During process monitoring, MCS300P also considers external parameters such as pressure, temperature, volumetric flow and oxygen content, ensuring maximum reliability in ranges from low to high concentrations (ppm …% vol).

MCS300P works with temperatures up to 200 °C and pressures up to 60 bar; the measuring cells are tested for safe use both with gases and inflammable, corrosive and toxic liquids. Furthermore, the photometer is available in a version for safe air or air classified as zone 1 and 2.

The integrated I/O modules and the Modbus, TCP and OPC communication protocols simplify the access and use of the analyzer, which can be controlled via an integrated display or a configuration and diagnostics software with remote access.