Special Coating for Heavy-Duty Bearings

IROX® 2, the polymeric motor bearing coating for heavy-duty applications developed by Federal-Mogul Powertrain, enhances seizure and fatigue performance, particularly with steel crankshafts.

by Andrea Baty

Following the launch of IROX® 2 for light vehicle engine bearings, Federal-Mogul Powertrain launched its new high-performance polymeric coating for heavy-duty applications.

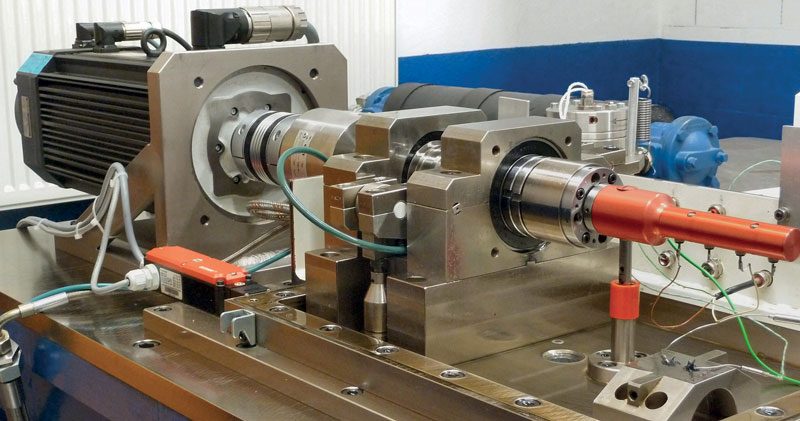

IROX 2 provides enhanced seizure and fatigue performance, especially with steel crankshafts. It is part of Federal-Mogul’s family of IROX technologies which reduce friction, improve efficiency and wear resistance while also enabling the use of lower viscosity oils. IROX 2 is already in series production in light vehicle engines. First heavy-duty projects have been nominated after successful tests. This coating extends the working range to fatigue load levels in the region of 100MPa, that traditionally required expensive PVD coated bearings. By reducing friction, the innovative IROX bearing coatings also help customers to lower fuel consumption and CO2 emissions. Evaluation using specific in-house developed test rigs showed that the reduction in friction when using IROX-coated bearings is bigger than that obtained by changing from 5W30 to

0W20 oil. While IROX was developed for crankshafts with a standard surface finish, IROX 2 is intended for crankshafts with extra smooth finish running with thinner oils. Due to its high adaptability, the polymeric coating material provides superior engine running-in characteristics.

Coatings are available for both aluminium and bronze engine bearings

Compared to aluminium based materials, which are also starting to establish themselves in the heavy-duty sector, both polymer coatings give reduced friction and greater wear resistance. In comparison to IROX, IROX 2 features further enhanced seizure and fatigue performance. This enables Federal-Mogul Powertrain to offer each customer the optimum formulation for their specific application.

Both coatings, IROX and IROX 2, are available for aluminium and bronze bearing materials for light and heavy-duty engines and they are particularly effective in hybrid and start/stop applications that place additional demands on bearings through frequent re-starting. The overlay is a PAI (Polyamide-imide) polymer resin binder containing a number of additives dispersed throughout the matrix. Developing IROX 2 involved modification of the binder system on a molecular level, coupled with subtle changes to the composition. For example, compared to IROX, IROX 2 contains no silicon carbide particles and has a higher content of a synergistic mixture of solid lubricants.