Sustainability and reliability drive the development of servopumps

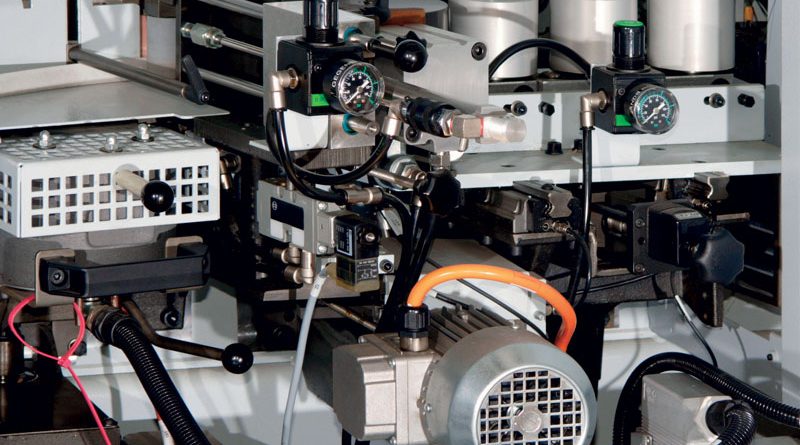

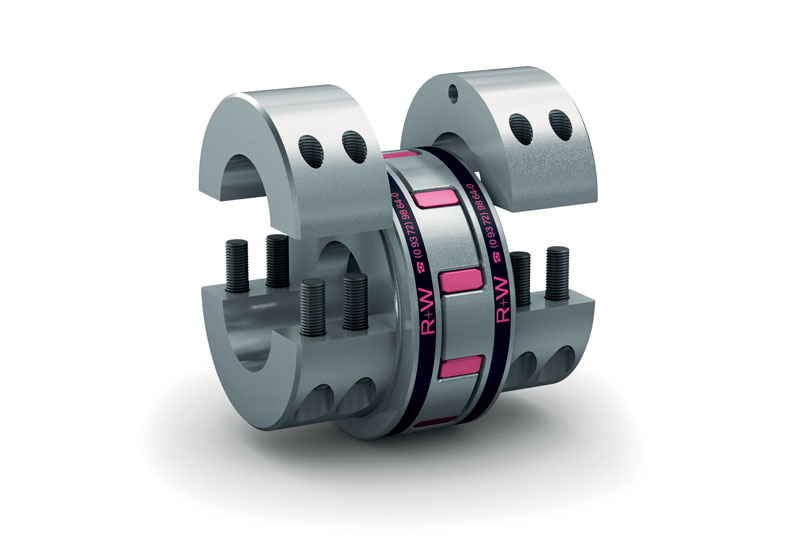

The servo pump and compressor market withstands the economic downturn with innovative, high-performance and sustainable solutions. New pumping systems are developed with the aim of maximising energy savings in all applications, while alternative maintenance models extend the life of machinery and increase its reliability. R+W’s EK couplings, which are also available in an AIC version with integrated sensors, are primarily intended for servo pumps for dosing and plastic injection machines.

The energy efficiency of machinery must comply with European objectives requiring the saving of resources and the progressive reduction of CO2 emissions by 2030. In this scenario, Assopompe (the trade association member of ANIMA-Confindustria), is collaborating with organisations and universities on a research project concerning new technologies for pumping systems, with the aim of maximising energy savings in all applications. And Italian industry is already doing its part by developing and implementing more efficient hydraulic solutions and latest-generation control systems.

More efficient and more sustainable pumping systems

Superior controllability and a higher level of performance are the two factors which make the difference between traditional pumps and servo-pumps, which are driven by low-consumption electric motors. In addition to providing greater acceleration, they are distinguished by the fact that they are always controlled by an intelligence, a drive that governs their activity and optimises their operation. Performance improves with less energy demand.

Driven by a servomotor, the servo-pump ensures adequate thrust only when it is actually needed: in addition to double-digit savings in energy costs, this results in better processing quality. Sustainability is another added value from which not only the industries but the whole community benefits, thanks to the reduction of CO2 emissions.

The functioning of the compression and pumping systems

Used in most segments of mechanical engineering, pumps and compressors are constantly evolving; they operate over a wide range of pressures, flows, working fluids and environmental conditions. These machines, once installed, require periodic upgrades, routine maintenance and inspections to keep them running safely and efficiently, but because corrosion rates and structural integrity depend heavily on operating conditions and design, in terms of the technical solutions adopted and materials used, it is not always easy to know when to do this.

Reliability and consistent performance are the two main requirements

As a failure of pumps or compressors can lead to costly downtime, purchasers of such machines demand ever-higher reliability and consistent performance over time. However, much of the information about the true reliability of this equipment depends on operating conditions. To respond to customer demands, manufacturers can operate in two ways:

– By creating macro-classes based on the conditions of use and increasing preventive maintenance, so as to underestimate the life cycle of components thus avoiding the occurrence of unexpected failures; however, this method involves a large amount of downtime, often to replace parts that are still fully – By creating dedicated models for micro-classes based on conditions of use. However, this choice leads to an enlarged catalogue for the manufacturer, who is thus faced with high costs and machines that are almost customised for each customer.

These are two opposing ways of working; even their synergistic use is not very efficient, since the former is a disadvantage for the purchasing company and the latter for the manufacturing company.

Knowing when and where to act

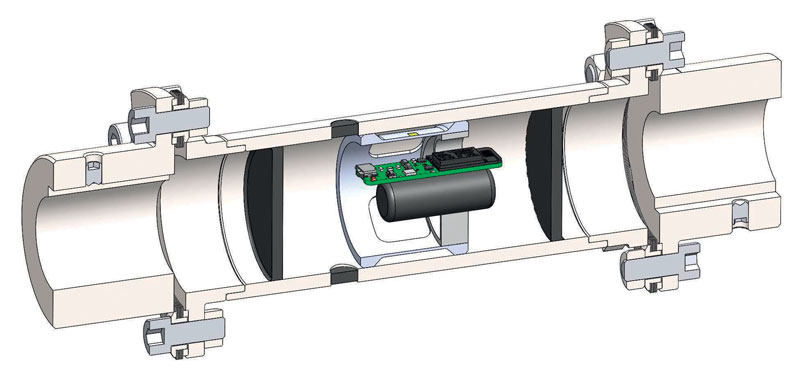

In recent years, thanks to the advent of the Internet of Things and Industry 4.0, technology has opened up new possibilities. Compressors, pumps and the entire kinematic chain that connects them to the surrounding system have been made smart, that is, capable of collecting data during operation and transmitting them to other IoT monitoring and analysis systems. This interconnection between the company’s production units is also reflected in the data collected, which, once analysed, can reveal faults at an early stage and identify the chain of causes which generated them.

To this end, models have been developed which examine information from the entire line and compare it with other historical data under perfect operating conditions, so as to indicate any deviation from the predicted measurements and, by means of a history of failures and in-depth knowledge of the machines, predict the health of each component. All this makes it possible, firstly, to avoid unexpected failures and, secondly, to provide more in-depth knowledge of the machines, which is especially useful to the R&D department for product improvement.

Preventive maintenance, which used to be ineffective for these machines, is thus transformed into predictive maintenance, thanks to knowledge of the real RUL (Remaining Useful Lifetime) of the parts that make up the production system.

The methods proposed by scientific research

Several case studies have been carried out on this subject, some of which have been presented in literature to serve as a guide for future applications. Among the most interesting is the one conducted by the University of Leicester in collaboration with Nanjing University (Xiaochuan Li and Xiaoyu Yang et al., 2019). In this work, a new diagnostic and prognostic model for incipient failure detection and RUL estimation of rotating machinery is proposed.

Using a monitoring index based on canonical variable analysis (CVA), which takes into account the distinctions between past and future canonical variables, an initial fault diagnosis is made which is then followed, through a new approach based on Pearson correlation analysis and the exponential moving average technique, by the identification of the most influential variables which can be associated with the fault. This approach solves two very common problems in this field: the management of a scarce amount of data and the quantification of the uncertainty of the remaining life of the components in a probabilistic form. One of the examples analysed was a high-pressure centrifugal pump used in a refinery in Europe. By analysing 13 variables (including speed, inlet and outlet pressure, fluid temperature, vibrations and bearing temperatures) over 580 hours, the model was able to detect the progression of conditions that were slowly leading to the failures which subsequently led to the pump’s breakdown, accurately distinguishing them from normal operating conditions. The same method was applied to analyse the failure conditions of a centrifugal compressor, successfully identifying the cause of the failures, which in this case were due to radial vibrations in the machine.

A similar model was developed in the study presented by Tayaba Abbasi et al. in the 11th Curtin University Technology, Science and Engineering (CUTSE) conference in 2018, in which a machine learning algorithm based on a recurrent neural network using long-term memory was used to perform predictive maintenance of an air booster compressor of a gas pipeline. Compared to the previous method, this has the advantage of not requiring specific know-how of the machinery on which it is implemented and the disadvantage of needing more data and time to train the neural network before it is usable.

The role of the coupling supplier

Between the motor and the pump there is a coupling, whose quality would not make a difference in a conventional motor pump, but is decisive in the case of servo-pumps, which require excellent components with excellent torsional rigidity helping to raise the performance level of the servo-pump assembly. These are the characteristics of the R+W precision elastomer couplings of the EK series, which are characterised by high torsional rigidity and no angular backlash. These couplings bring with them a surplus of efficiency; at the same time, they support increased productivity and it is easy to imagine that in injection moulding companies with dozens of machines on which there are sets of several servo pumps, they guarantee a reduction in energy expenditure. It is precisely for servo pumps for plastic injection and dosing machines that R+W’s EK couplings are primarily intended, and this is where most of the company’s customers are to be found. Since the common theme linking pumps and compressors is the analysis and collection of data from these machines and their associated components, components capable of measuring different types of data can be crucial. This is why R+W also supplies EK couplings in the AIC version with integrated sensors.