Technology and innovation in fruit pitting

By integrating Mitsubishi Electric’s automation solutions, CTI Foodtech provides the market with state-of-the-art solutions for fruit pitting. The machines built by the Salerno-based company are equipped with brushless motors and servo drives of the MR-J4 or MR-JE families, connected to the iQ-F compact automation platform. The motion control is entrusted to the Simple Motion Module installed on the PLC, while a FR-D700 inverter and configurable recipes allows the machines to be adapted to different sizes.

Thirty years of experience, more than a hundred patents and over 600 machines installed on five continents make CTI FoodTech a pioneering company in the field of industrial fruit processing machinery. In particular, the company is the second manufacturer of peach pitters for number of units installed in the world.

Thanks to Mitsubishi Electric solutions integrations into its machinery, CTI Foodtech introduced innovative machines for pitting fruit on the market, ensuring unique overall performances. CTI FoodTech’s machines are equipped with brushless motors driven by the MR-J4 or MR-JE families’ servodrives connected to the Mitsubishi Electric iQ-F compact automation platform. The motion control system uses the high-speed fiber optical SSCNET III / H Motion Bus network. The main PLC manage the data coming from the sensors on field and the operator can handle them from the GOT GS operator panel. Moreover, through to FR-D700 inverter Mitsubishi Electric and recipes realized with HMI, the machine can be adapted to different fruit sizes.

New patented automatic feeding system

The partnership between CTI Foodtech and Mitsubishi Electric allowed the development of new-patented automatic feeding system “CTI-FAS” that place automatically fruits with different size, in particular pears, adapting to horizontal and vertical coring machines. The fruit is first oriented and processed through the stalk cutting station (capable of multiple cutting) and then conveyed to the subsequent de-stemming and peeling stations.

The implementation of a 4-axis solution with Mitsubishi Electric motors on the machine made it possible to optimise machine operation and maximise its yield.

MR-J4 and MR-JE servo system’s Mitsubishi Electric guarantee high reliability of the drive system, considered as a key factor for this type of production. Moreover, thanks to the HMI touch screen GOT2000 from Mitsubishi Electric, the machine can be easily adapted to different fruit sizes.

Thanks to the touch screen panel of the Mitsubishi Electric GOT2000 family, the machine can be easily adapted to different fruit sizes.

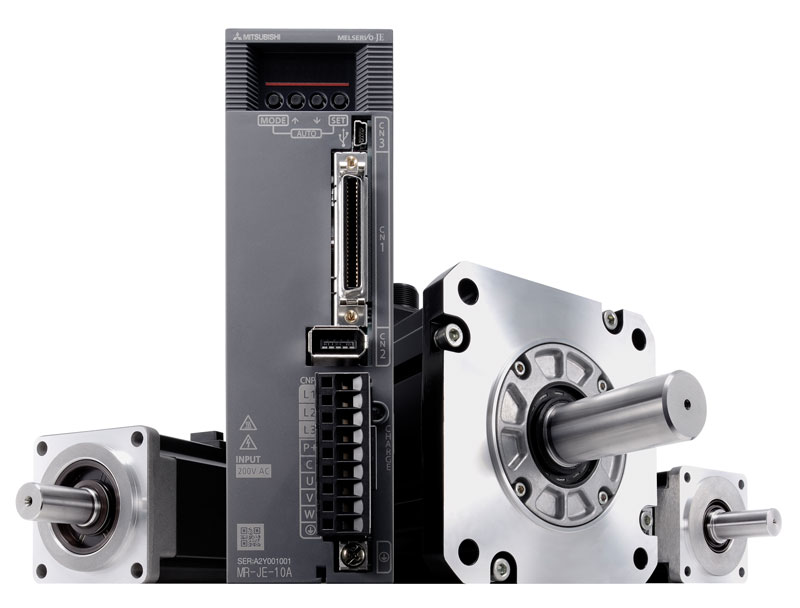

Mitsubishi Electric’s MR-JE family of servo systems.

High-performance, user-friendly servo motors

The MR-J4 family of Melservo servo motors offers a complete, user-frinsdly and easily commissioned solution, offering high performance and a number of outstanding features. The MR-J4 servo motor meets the needs of the most challenging applications including packaging machines, rotary tables and handling systems. The many innovative features aim to minimise time-consuming system adaptations between mechanics and electronics.

Commissioning and parameterisation times are extremely short thanks to the ‘one-touch tuning’ and ‘vibration suppression’ functions, available both at start-up and during operation. The amplifiers also feature a “Life Diagnosis Function”. This function monitors condition and quality of the internal components throughout their life cycle and alerts the operator to any faults. In this way, downtimes and machine stoppages are practically excluded.

The automatic vibration suppression function optimally controls all mechanical kinematics by eliminating vibrations. Maximum positioning accuracy and speed are guaranteed by the 22-bit absolute encoder (over 4 million pulses/revolution) built into the servomotors as standard.

Melservo MR-J4 family servomotors guarantee maximum positioning accuracy and speed thanks to the 22-bit resolution absolute encoder (over 4 million pulses/revolution) integrated as standard.

The iQ-F compact automation platform features two Simple Motion Modules, FX-40SSC-S with 4 axes or FX80SSC-S with 8 axes.

Compact automation platform for a cost-effective motion solution

The iQ-F compact automation platform features two Simple Motion Modules, FX-40SSC-S with 4 axes or FX80SSC-S with 8 axes, allowing users to implement powerful and cost-effective Motion Control solutions. It can perform PTP positioning, linear or circular interpolation, electronic cams, axis synchronisation, cutting on the fly and so on, solving Motion Control applications with compact PLCs. The Simple Motion Modules control via the SSCNET III/H fibre optic motion bus both the MR-J4-B-RJ and MR-JE-BF servos, both with integrated STO safety function as standard. The use of the MR-JE-BF servos provides a cost-effective Motion solution.

Absolute encoders are installed on the servomotors as standard, while the drive incorporates a “one-touch tuning” function allowing the kinematic parameters of the system to be automatically adjusted. The following functions are also included: the vibration suppression function, which eliminates mechanical shocks, the “drive recorder” function, which continuously records the parameters of the servo system, storing them when an alarm occurs. The analysis of the parameters obtained by using the oscilloscope function allows any problem to be immediately identified. Configuration, programming, setup and debugging of the system is performed by the GX Works 3 software, a tool capable of handling all the functions of the FX5-40SSC-S and FX5-80SSC-S Simple Motion Modules.