The Latest News in the Field of Hydraulic Pumps and Motors

The new series of radial piston motors “Staffa” HPB and the renewed variable displacement axial piston pump for open circuit K3VL series, both of them produced by Kawasaki, are among the novelties distributed by HANSA-TMP, the well-known producer and distributor of hydraulic components.

HANSA-TMP is a well-known manufacturer of electro-hydraulic and hydraulic components. For over twenty years, the company has been distributing some of the major brands of the sector: the entire Kawasaki production range being one of them. The Modena-based company HANSA-TMP is thus able to supply most of the components required by a hydraulic circuit. The new series of radial piston motors “Staffa” HPB and the renewed variable displacement axial piston pump for open circuit K3VL series are among the highlights. In 1916, over 100 years ago, Kawasaki began manufacturing Hele-Shaw type radial piston pumps. Today, it is a world leader in the hydraulics industry, manufacturing a wide range of products, from hydraulic pumps, motors, valves and electrical controllers, to hydraulic systems for mobile, industrial and marine applications.

Fixed displacement motors are perfect for industrial applications

In 1957, George Hally Junior, who called it the “Staffa” motor, designed the first hydraulic radial piston motor. Originally designed to work in the harsh environment of a coalmine, the Staffa motor was quickly found to be a tough and reliable product, it soon became popular wherever a reliable direct drive solution was required. In the decades that have followed, modern techniques such as Finite Element Analysis (FEA), materials handling and coatings, Computational Fluid Dynamics, evolved and refined the motor design, allowing it to push the operating boundaries of this unique family of motors. The HPB is the optimal fixed displacement motor for industrial applications. In relation to the different Staffa models, you can select the required displacement, minimum 983 cc/rev – maximum 5,310 cc/rev, and reaching a maximum intermittent pressure of 300 bar. With a maximum speed of 450 rpm, it is faster than the previous standard HMB motor and, for the same displacement, it has up to 100% more power and, with flushing, it increases its useful life by 83%, reducing costs and downtime. Currently, more than 500,000 motors have been sold, many of which are still in use, after thousands of hours in trouble-free service.

Axial Piston Pumps are the best choice for limited spaces

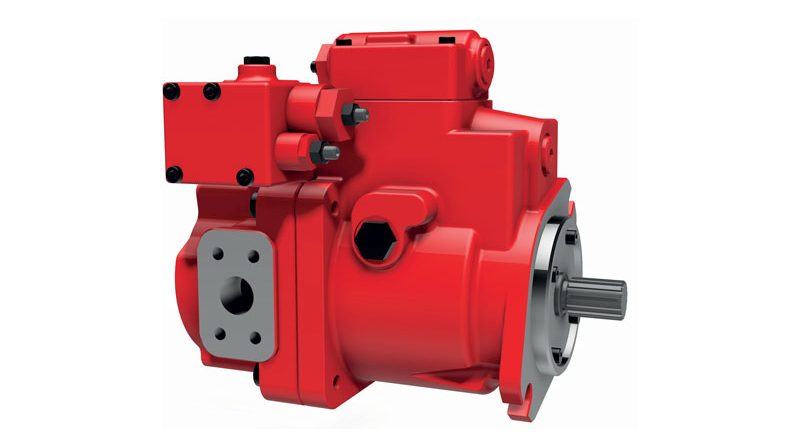

The innovative K3VL series variable displacement axial piston pump for open circuit covers a wide range of flow rates, from 28 to 200 cm3/rev, with various options: pressure limiter, torque limiter and Load Sensing. With a great sensitivity to the dynamics of working conditions, combined with the speed of response, K3VL are at the top of the category. The excellent weight/power ratio and the small size of the pumps make the use of the K3VL optimal in all applications that require limited space and weight. The exclusive self-regulation and control system allows a simple and versatile setting (with a few and easy operations you can switch from one control to another). The continuous development of the construction technology of the internal components of the pump allows reaching a high efficiency, with values hardly achievable by similar products.

The particular constructive shape of the oscillating plate for flow adjustment and the continuous technological development of pumping construction, have allowed to obtain a low level of noise even at high pressures (72 dB to 1500 rpm and 250 bar) with the direct, positive consequence of obtaining a better acoustic comfort for the operating environment. The high efficiency of the rotary unit requires a low stand-by torque, allowing a reduction in the temperature of the hydraulic system and, as a result, a lower fuel consumption. The K3VL series is also available in ATEX version, for use in potentially explosive atmospheres.