The Modular System for Direct Drive Rotary Tables Comes from a Single Source

The modular system for direct drive rotary tables and swivel-type axes offered by Schaeffler Group ensures more performance and precision in cutting tool operations. Torque motor, rotary table, and angular measuring system perfectly matched to each other, come from a single source, with all the advantages that come with it.

by Elena Magistretti

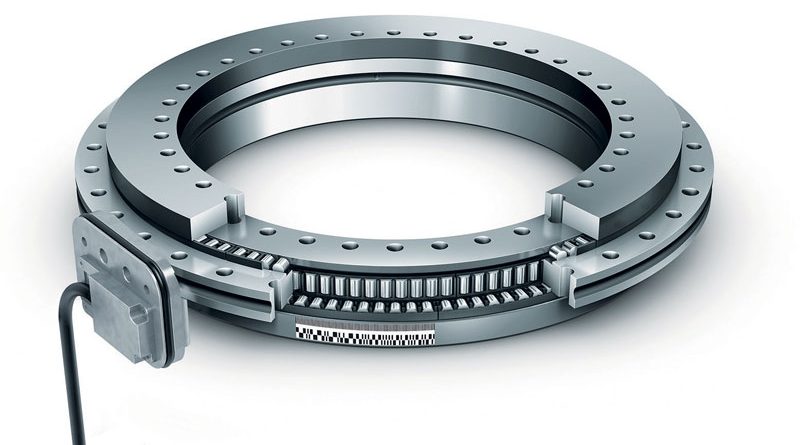

In directly driven rotary tables and swivel-type axes, the torque motor, the rotary table bearing, and the angular measuring system constitute a complex system with a large number of interactions regarding heat flow, cogging, speed and acceleration capability, rigidity, frictional torque, and positioning accuracy. It is therefore immensely beneficial if all three components come from a single source and are perfectly matched to each other in one modular system. Schaeffler Industrial Drives, based in Suhl (Germany), offers three torque motor series for an extremely wide range of applications, while Schaeffler offers three FAG bearing series and an angular measuring system integrated into the bearing. Market requirements for higher speeds without any compromises in terms of rigidity remain strong especially for rotary tables in milling machines. Schaeffler has therefore optimized its proven YRT rotary table bearings using a new plastic cage, a more solid bearing ring, and a new rolling element geometry. The bearings developed for the YRTC X-life successor series offer machine tool operators increased speeds of up to 80 percent and up to 20 percent more tilting rigidity compared to the YRT series. Operators can thus obtain higher cutting performance while also achieving higher precision. The new YRTC X-life rotary axis bearings are also available with an angular measuring system integrated into the bearing (YRTCMA). The dimensional scale is affixed to the high-precision inner ring shoulder that runs completely true and is thus designed at bearing level. This arrangement achieves the highest possible measuring accuracy when the table is tilted. Moreover, costly ground connecting parts are not necessary as the measuring system is integrated into the rotary table bearing. All common absolute measuring protocols such as EnDat2.2, DRIVECLiQ, the Fanuc serial interface, and SSi1VSS are available with functional safety for the YRTCMA bearing. This allows integration into the standard control systems of machine tools. A reference run of the rotary axis does not need to be carried out due to the absolute value, offering maximum collision protection for the machine.

Torque motors for rotary tables and axes: precision to the limits of what is feasible

The requirement for increased manufacturing precision and lower noise is driving forward the development of torque motors with the fewest possible sources of malfunctions and the lowest possible power loss because the fewer there are the less outlay machine manufacturers need to invest to compensate deviations in the control system resulting from potential sources of malfunctions.

Schaeffler Industrial Drives has developed SRV and HSRV motors in order to reduce such deviations, which may occur in the grinding process of gear teeth due to cogging and holding torque for example, to levels approaching zero. They have a double motor structure, which cancels out the opposing radial magnetic disturbance forces. This prevents tilting of the rotation axis in the micrometer range right from the outset. The positive effect on the manufacturing quality is further reinforced by the motors requiring relatively low bearing preload as there are hardly any disturbance forces. The bearing therefore generates less frictional heat during operation, causing lower fluctuations of the bearing preload and the bearing rigidity.

Milling and turning operations: high torque and high speeds

The combined milling and turning operations are mainly characterized by precise track-accurate contours and high speeds in the turning mode. From the torque motor developer’s perspective, speeds of 800 rpm for table diameters of over 500 mm are technically very challenging, as the electric alternating frequencies of the motors with a high number of poles increase significantly. The motors warm up as well, with all the negative impacts for the entire drive including a change of the bearing’s preload and rigidity. For this segment, the motors of the RKI series have been launched onto the market. The development work in this case focused on expanding the torque motors’ typically low speed range without having to reduce the torque. The RKI motors are therefore equipped with a tooth coil winding and laminated rotors for reducing eddy current losses.

Development partnership with machine tool manufacturer

The trend towards high power yield and precision has caused customers today to regard motors and bearing supports as a functional unit. Details such as the simulation of the heat flow, the change in bearing preload, the achievable acceleration capability, and many more, are discussed in depth with the customer if required, in order to adapt individual motor topologies precisely to customer-specific drive tasks – in some cases even to the limit of what is technically feasible.