Thin Section Bearings Travelling 400 kilometres above the Earth

Thin section bearings angular contact from Kaydon will do their work in a robot on the outside of the International Space Station (ISS). Kaydon’s bearings will guarantee trouble-free movements for the articulations of that robot. They were considered as the best possible choice on the basis of their accuracy, reliability, their efficiency in absorbing both radial and axial forces and their particularly space-saving design

by Elena Magistretti

Thin section bearings from Kaydon will do their work in a robot on the outside of the International Space Station (ISS) about 400 kilometres above the surface of the Earth.

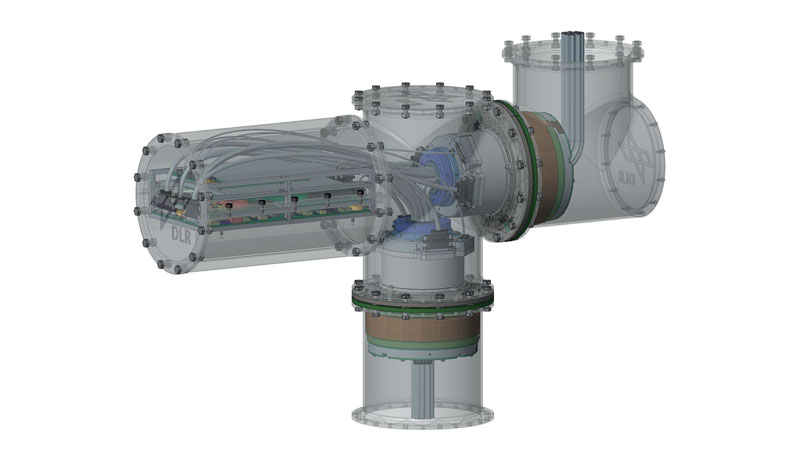

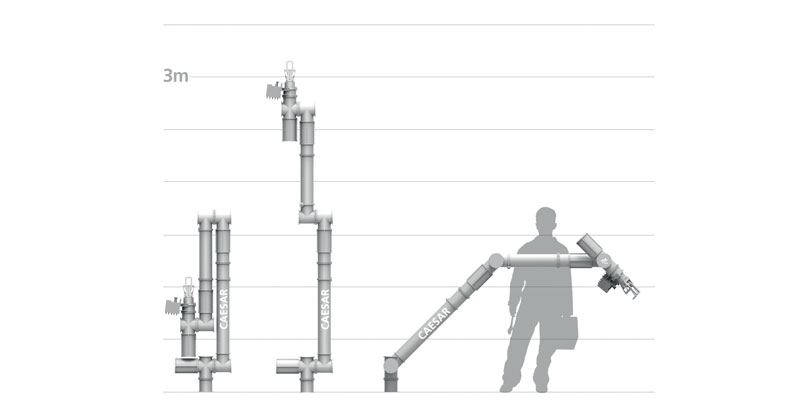

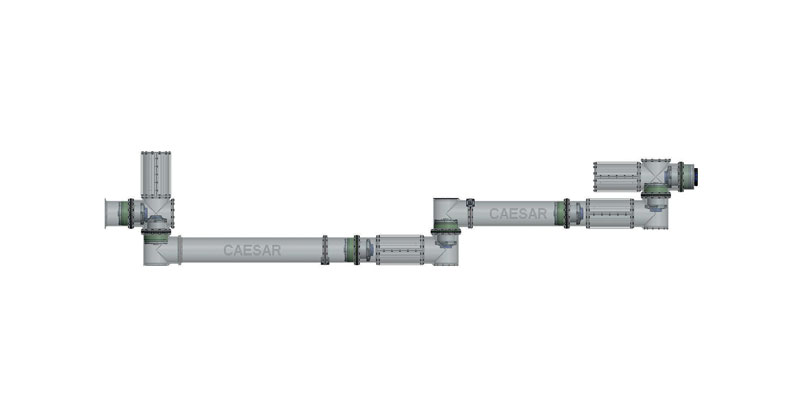

CAESAR (Compliant Assistance and Exploration SpAce Robot ) is equipped with a three-metre long arm with seven articulations whose function will be to attend to the performance of scientific and commercial experiments in conditions of weightlessness.

The robot weighing 60 kilograms will be transported up to the weightless conditions of the ISS, where it will be installed 400 kilometres above the Earth’s surface. This is where the exceptionally flexible folding robot arm will work, grabbing and stabilising satellites which are orbiting erratically or have become unresponsive. The German Aerospace Center (DLR), which developed CAESAR, can draw on an immense fund of experience with robots in space. A robot from the DLR was already operational on the ISS from 2005 to 2010 as part of the ROKVISS project (Robotic Components Verification on the ISS). Thin section angular contact bearings from Kaydon successfully guaranteed trouble-free movements for the articulations of that robot thanks to their load-bearing capability, reliability, and indeed the experience in space applications.

Drawing on experience with the previous project

For CAESAR, researchers were able to draw on the many experiences gained with ROKVISS, which was partially controlled from Earth. “With ROKVISS, ‘force feedback’ on the ISS was used to test how precisely the robot arm can be manipulated with a joystick. This enables the operator on Earth to feel the force with which the robot in space is pressing against its environment. The prototype of the space robot arm was brought back to Earth in a Soyuz capsule in 2011, and the data on its state of wear was used by scientists as a basis for constructing the new model.

Now, CAESAR is the continuation of the force- and torque-controlled robot systems for the DLR and the space counterpart of modern service robots which are used in manufacturing and for human-robot cooperations. The new generation of robots combines innovative electronic and mechanical engineering. For example, the robot has seven degrees of freedom. This number of freely selected motion capabilities thus matches that of the human arm, endowing it with greater flexibility than standard robots. The basis for the robot that was built for research and assistance in space is the lightweight robot III, which was developed by the Institute and transferred to the world’s leading robot manufacturer. KUKA, in 2003.

Trouble-free motion and force control

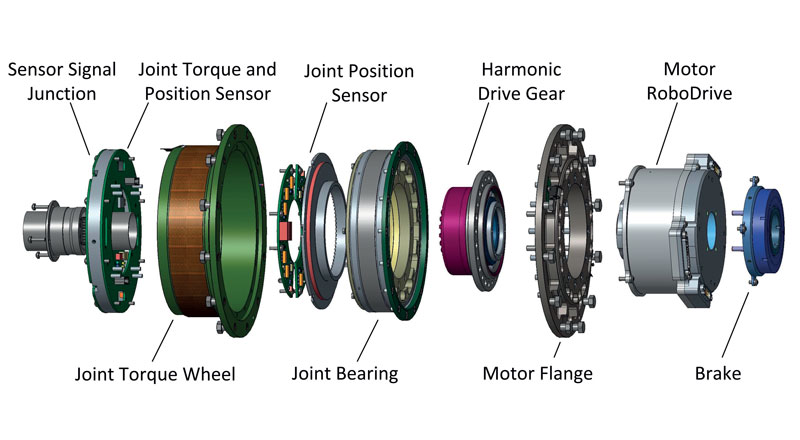

CAESAR can be operated semi-autonomously, by telecommand or with telepresence and force feedback. The impedance controller allows the arm articulations to yield and prevents them from damaging objects. The integrated torque sensor system detects unintended contact with the surroundings and enables appropriate responses, which represents a critical safety feature particularly in cooperation with astronauts. Since there is no gravitational load in space, all connections have the same torque capacity. Fast control circuits in the articulations and a high-speed, real-time communications bus connecting the articulations to the Robot Control Unit (RCU) ensure trouble-free motion and force control.

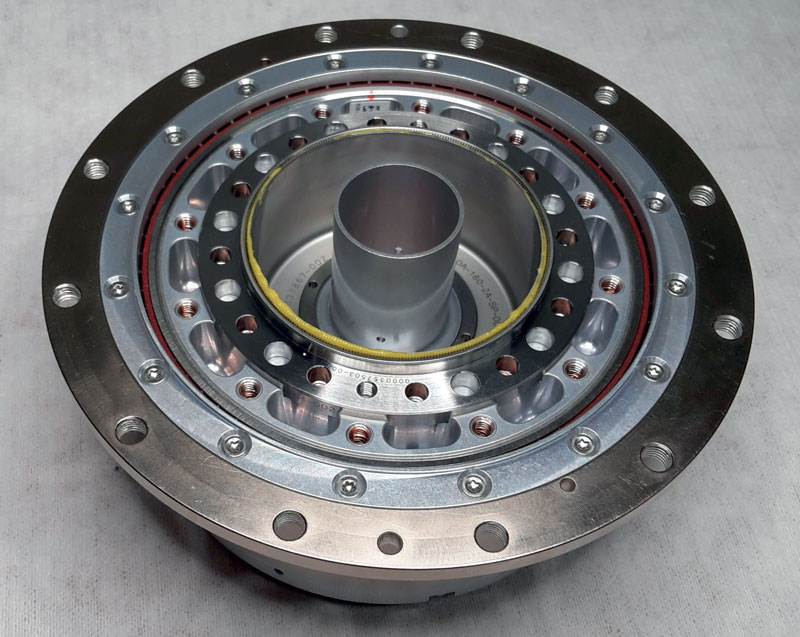

The connective construction includes a hollow shaft to enable internal wiring. Each articulation consists of a synchronous motor with a commutation sensor, a harmonic drive pinion and angular contact bearings, the torque sensor and a common position sensor. The choice of thin section angular contact bearings was made on the basis of their efficiency in absorbing both radial and axial forces and their particularly space-saving design. The Reali-Slim series, on which the thin section bearings used here are based, can withstand the harshest operating conditions. They feature a compact design, outstanding precision, and they are ideal for applications with such extreme demands.”

Permanent passenger in orbit

Since most services in future will be provided for geostationary satellites, the radiation hardness and service life of CAESAR have been planned for fifteen years’ operation in geostationary orbit.

The robot as a whole is designed for temperatures between -20° Celsius and +60° Celsius. There are plans to build this system for further requirements as well. For this, it must be able to be adapted to various carriers, satellites or spacecraft. Production and qualification of the system must be efficient and precise to enable financial success.

Nicole Dahlen, Managing Director with responsibility for Sales, Marketing and Organisation with Rodriguez GmbH, Kaydon’s partner in this project.