Wear-free magnetic hysteresis couplings

The permanent-magnetic hysteresis coupling MINEX-H series of KTR Systems, and distributed by Mondial, transmit the torque via magnetic forces; it is available in three sizes for overload torques from 1.2 to 6 Nm with a maximum speed of 1,800 RPM.

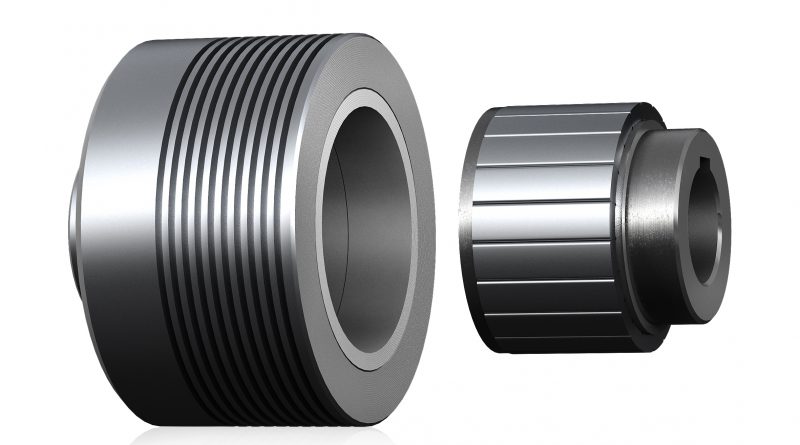

Mondial distributes permanent-magnetic hysteresis couplings MINEX-H series, developed by KTR Systems, which transmit the torque synchronously and contactless between the internal and external rotor via magnetic forces.

The particular feature of this new product is the integrated overload protection: when the operating torque exceeds the selected torque, the coupling slips while ensuring wear-free torque limitation.

Apart from that the coupling can be applied as a brake in permanent slipping operation. In this case one rotor side is fixed while the other rotor side limits the tensile force set.

For overload torques up to 6 Nm with a maximum speed of 1,800 RPM

The internal rotor of MINEX-H is a hub made of stainless steel which the nickel-plated permanent magnets are arranged on. The external rotor is made up of an aluminium body that the hysteresis rings are located on. The new series is currently available in three sizes for overload torques from 1.2 to 6 Nm with a maximum speed of 1,800 RPM.

Main fields of application of the hysteresis coupling are low speed applications with frequent or permanent slipping; these include, inter alia, filling plants, winding and unwinding plants as well as medical and materials handling technology.